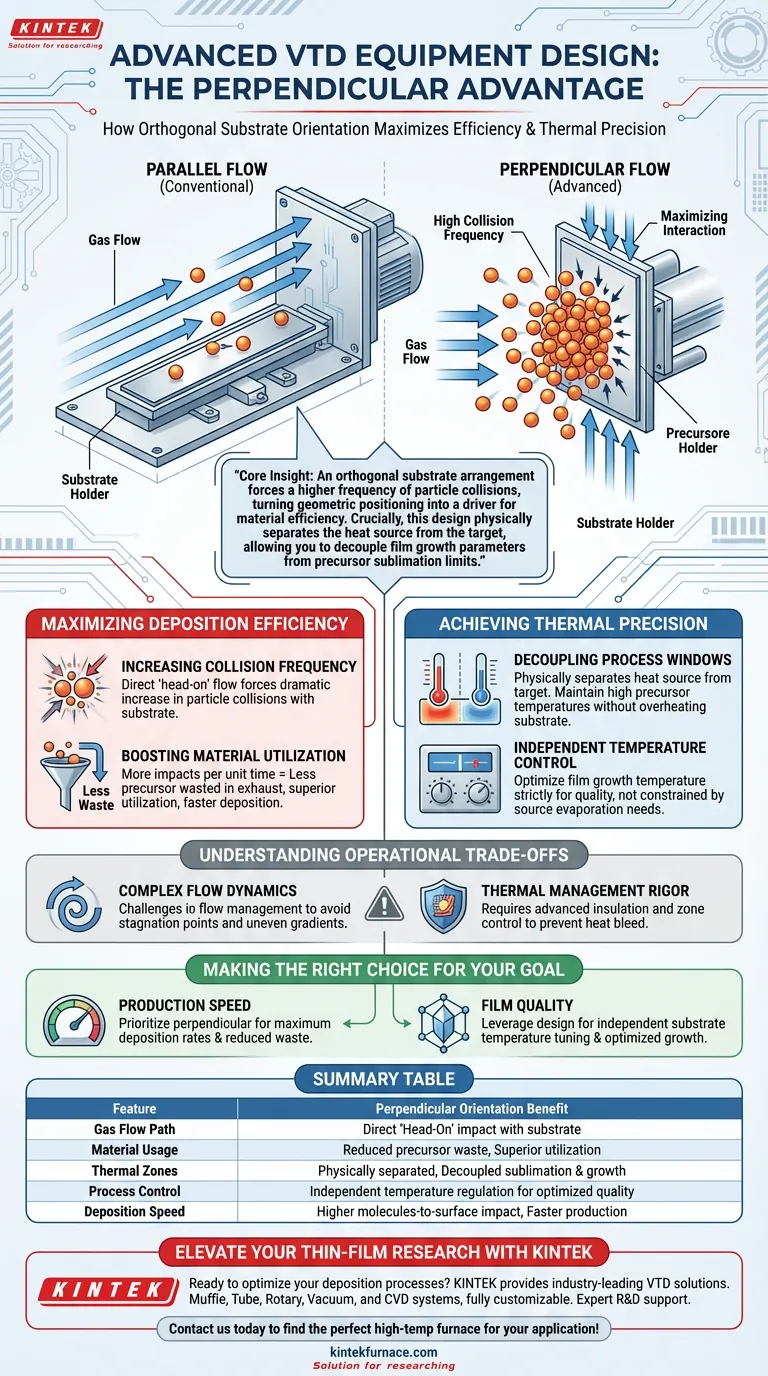

In advanced Vapor Transport Deposition (VTD) systems, orientation dictates efficiency. Placing the substrate holder perpendicular (orthogonal) to the gas flow creates a direct physical obstruction to the vapor path. This geometric arrangement maximizes the interaction between the active precursor and the target surface, resulting in significantly improved deposition rates and critical process flexibility.

Core Insight: An orthogonal substrate arrangement forces a higher frequency of particle collisions, turning geometric positioning into a driver for material efficiency. Crucially, this design physically separates the heat source from the target, allowing you to decouple film growth parameters from precursor sublimation limits.

Maximizing Deposition Efficiency

Increasing Collision Frequency

In a perpendicular configuration, the gas flow travels directly toward the substrate rather than skimming parallel to it. This "head-on" approach forces a dramatic increase in the collision frequency between the active precursor vapors and the substrate surface.

Boosting Material Utilization

Because more precursor molecules impact the surface per unit of time, less material is wasted in the exhaust stream. This results in superior utilization efficiency and faster overall deposition rates compared to parallel flow designs.

Achieving Thermal Precision

Decoupling Process Windows

A major limitation in standard VTD is the thermal link between the source and the substrate. The perpendicular design facilitates the decoupling of thermal zones. You can maintain the high temperatures required for precursor sublimation without inadvertently overheating the substrate.

Independent Temperature Control

This separation allows for independent and precise temperature regulation of the substrate holder. Consequently, engineers gain the flexibility to optimize the film growth temperature window strictly based on film quality requirements, rather than being constrained by the evaporation needs of the source material.

Understanding the Operational Trade-offs

Complexity of Flow Dynamics

While orthogonal flow enhances collision, it introduces challenges in flow management. Creating a uniform deposition across the entire substrate requires careful design to avoid stagnation points (where flow stops at the center) or uneven gradients at the edges.

Thermal Management Rigor

Decoupling the temperatures provides flexibility but demands a more sophisticated control system. The equipment must be capable of maintaining distinct thermal environments in close proximity, requiring advanced insulation and zone control to prevent heat bleed between the source and the substrate.

Making the Right Choice for Your Goal

To determine if this VTD configuration aligns with your objectives, consider your primary processing needs:

- If your primary focus is Production Speed: Prioritize the perpendicular orientation to maximize deposition rates and reduce precursor waste through high collision frequency.

- If your primary focus is Film Quality: Leverage this design to independently tune the substrate temperature, ensuring the growth environment is optimized regardless of the source material's volatility.

The perpendicular alignment transforms the substrate holder from a passive target into an active tool for process optimization.

Summary Table:

| Feature | Perpendicular (Orthogonal) Orientation | Benefit |

|---|---|---|

| Gas Flow Path | Direct "Head-On" impact with substrate | Increases particle collision frequency |

| Material Usage | Reduced precursor waste in exhaust | Superior material utilization efficiency |

| Thermal Zones | Physically separated source and substrate | Decouples sublimation from film growth |

| Process Control | Independent temperature regulation | Optimized film quality and growth windows |

| Deposition Speed | Higher molecules-to-surface impact rate | Faster production and throughput |

Elevate Your Thin-Film Research with KINTEK

Ready to optimize your deposition processes? KINTEK provides industry-leading VTD solutions designed for precision and efficiency. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory and production needs.

Whether you require independent thermal zone control or enhanced material utilization, our expert team is here to support your success. Contact us today to find the perfect high-temp furnace for your application!

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do heat treatment furnaces function? Master Thermal Control and Atmosphere for Superior Material Properties

- Why is immediate quenching required after CTS treatment of mesoporous carbon? Preserve Your Material’s Atomic Structure

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- What are the energy consumption considerations when choosing between separate or combined debinding and sintering furnaces? Optimize Your Process Efficiency

- What role does a laboratory drying oven play in catalyst supports? Ensure Structural Integrity & High Dispersion

- How do heating devices and alkaline impregnation tanks coordinate in biochar activation for maximum adsorption?

- How does a high-precision temperature control system affect high-entropy materials? Unlock Material Performance

- What role do RTP or continuous sintering furnaces play in solar cell electrode formation? Optimize Your Firing Process