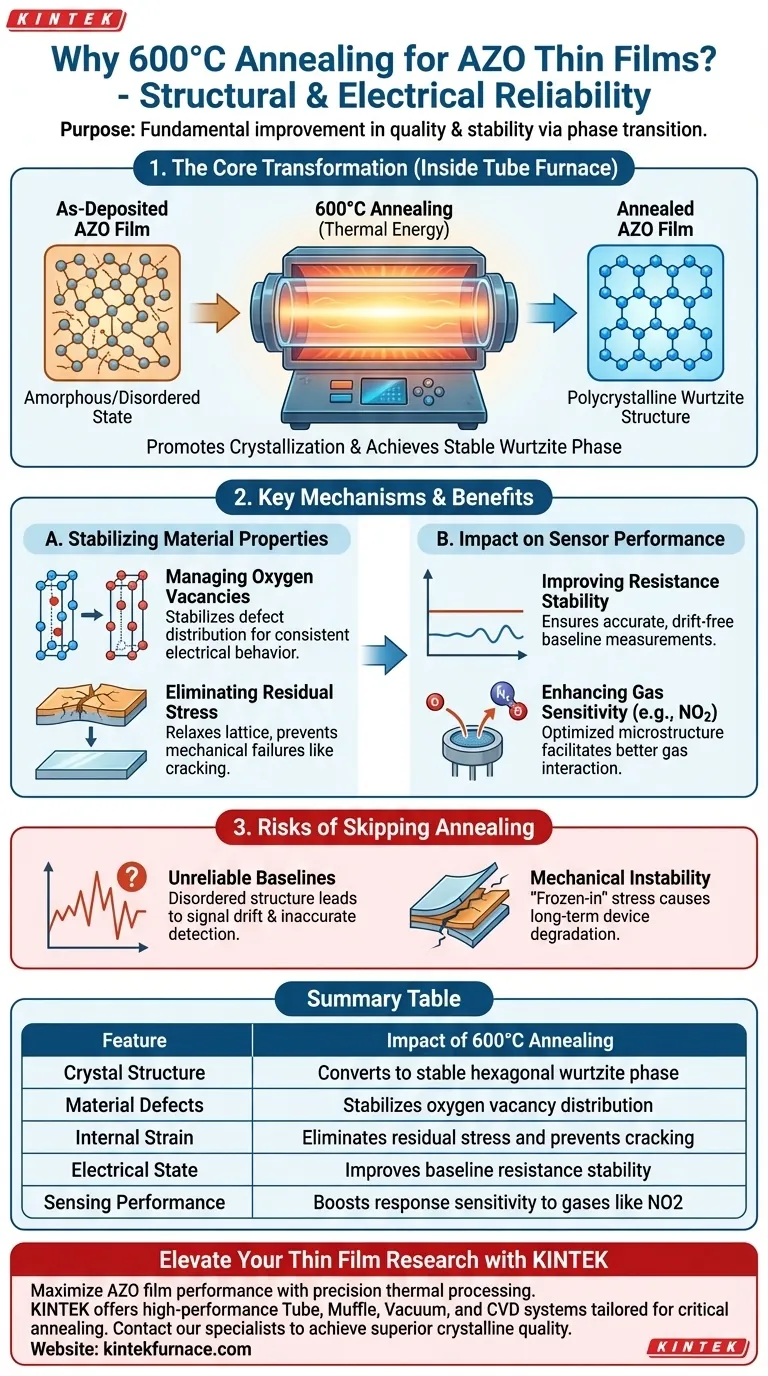

The primary purpose of performing a 600°C annealing treatment on Aluminum-doped Zinc Oxide (AZO) thin films is to fundamentally improve their structural quality and electrical reliability. This high-temperature process drives a phase transition that converts the as-deposited film into a stable, highly ordered crystalline material.

Annealing serves as a critical stabilization step that converts the AZO film into a polycrystalline hexagonal wurtzite structure. By refining the crystal lattice and managing oxygen vacancies, this process significantly enhances the material's baseline stability and boosts its sensitivity for gas sensing applications.

Optimizing the Crystalline Structure

Promoting Crystallization

The thermal energy provided by the tube furnace promotes the crystallization of the AZO thin film. This transforms the material from a potentially disordered or amorphous state into a defined polycrystalline form with higher crystalline quality.

Achieving the Wurtzite Phase

Specifically, the annealing process converts the microstructure into a hexagonal wurtzite structure. This specific crystal lattice configuration is desirable because it optimizes the material's physical properties for electronic applications.

Stabilizing Material Properties

Managing Oxygen Vacancies

Annealing is essential for defect engineering; it helps stabilize the distribution of oxygen vacancies throughout the film. Since oxygen vacancies act as charge carriers in oxide semiconductors, their stable distribution is vital for consistent electrical performance.

Eliminating Residual Stress

Deposition processes often leave thin films under significant internal strain. The 600°C treatment relaxes the lattice, effectively eliminating residual stress. This prevents mechanical failures such as cracking or delamination and ensures uniform electronic behavior.

Impact on Sensor Performance

Improving Resistance Stability

By removing stress and ordering the crystal structure, the film achieves higher baseline resistance stability. This means the sensor's electrical resting state does not drift unpredictably, which is a prerequisite for accurate measurements.

Enhancing Gas Sensitivity

The optimized microstructure directly increases the response sensitivity of the sensor. The primary reference notes this is particularly effective for improving the detection of nitrogen dioxide (NO2) gas, as the interaction between the gas and the film surface is facilitated by the improved material quality.

The Risks of Skipping Post-Deposition Annealing

Unreliable Baselines

If you omit the annealing step, the film retains a disordered structure with unstable defects. This results in fluctuating electrical resistance, making it difficult to distinguish between actual gas detection and mere signal drift.

Mechanical Instability

Without the stress relief provided by high-temperature treatment, the film remains under tension or compression. This "frozen-in" stress compromises the mechanical integrity of the device, leading to potential performance degradation over time.

Making the Right Choice for Your Goal

To maximize the effectiveness of your AZO thin films, consider your specific application requirements:

- If your primary focus is gas sensing precision: You must anneal to stabilize oxygen vacancies, which maximizes the film's response sensitivity to gases like nitrogen dioxide.

- If your primary focus is device longevity: You must anneal to eliminate residual stress, ensuring the film maintains a stable baseline resistance and does not degrade mechanically.

By controlling the thermal history of the film, you turn a raw deposited layer into a functional, high-performance sensing element.

Summary Table:

| Feature | Impact of 600°C Annealing |

|---|---|

| Crystal Structure | Converts to stable hexagonal wurtzite phase |

| Material Defects | Stabilizes oxygen vacancy distribution |

| Internal Strain | Eliminates residual stress and prevents cracking |

| Electrical State | Improves baseline resistance stability |

| Sensing Performance | Boosts response sensitivity to gases like NO2 |

Elevate Your Thin Film Research with KINTEK

Maximize the performance of your AZO thin films with precision thermal processing. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems tailored for critical annealing applications. Whether you are optimizing gas sensors or developing advanced electronic materials, our customizable lab furnaces ensure uniform heating and reliable results.

Ready to achieve superior crystalline quality? Contact our specialists today to find the perfect high-temperature solution for your unique laboratory needs.

Visual Guide

References

- So-Young Bak, Moonsuk Yi. Transparent Al-Doped ZnO Thin Films for High-Sensitivity NO2 Gas Sensing. DOI: 10.3390/s25123622

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What industries benefit from the use of tube furnaces? Unlock Precision in Semiconductor and Battery Tech

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing