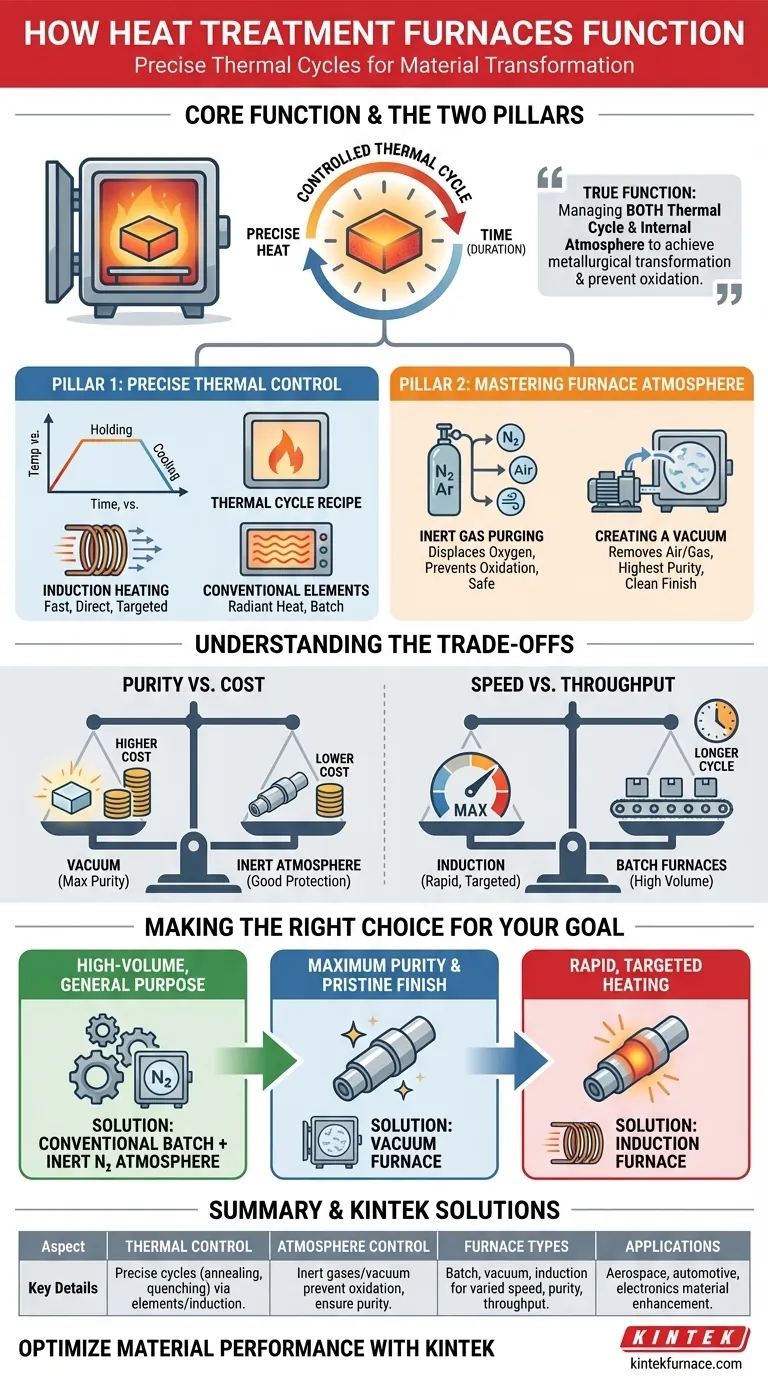

At its core, a heat treatment furnace functions by heating materials to a precise temperature and holding them there for a specific duration. This controlled thermal cycle is designed to deliberately alter a material's internal structure, thereby changing its physical and mechanical properties like hardness, strength, or ductility. The process is not just about applying heat, but about applying it with absolute precision.

The true function of a heat treatment furnace goes beyond simple heating. It is a system for meticulously managing both the thermal cycle and the internal atmosphere to achieve a desired metallurgical transformation while preventing unwanted side effects like oxidation.

The Two Pillars of Heat Treatment

Effective heat treatment relies on the perfect management of two fundamental variables: the temperature profile and the surrounding atmosphere. The furnace's design is entirely centered on controlling these two factors.

Pillar 1: Achieving Precise Thermal Control

The goal of thermal control is to execute a specific heating and cooling recipe, known as a thermal cycle. The rate of temperature change is often as important as the peak temperature itself.

Heating methods are chosen based on the speed, precision, and efficiency required. Induction furnaces, for example, use a powerful electromagnetic field to rapidly and directly heat a conductive part, offering exceptional control over the process.

Other furnaces use more conventional heating elements, often made from specialized alloys or ceramics, to radiate heat throughout the chamber. The choice depends on the material being treated and the desired outcome, such as annealing, quenching, or tempering.

Pillar 2: Mastering the Furnace Atmosphere

Simply heating a metal in open air can be disastrous, leading to oxidation (rust), scaling, and a ruined surface finish. The furnace's second critical job is to control the atmosphere surrounding the part.

Inert Gas Purging A common method is to "inert" the furnace by purging it with a non-reactive gas like nitrogen or argon. This process displaces oxygen, moisture, and other contaminants.

This serves two purposes: it prevents oxidation on the component's surface and enhances safety by removing any potentially flammable gases from the chamber.

Creating a Vacuum For applications demanding the highest level of purity, a vacuum furnace is used. These are sealed chambers where powerful pumps remove virtually all air and gas before the heating cycle begins.

By creating a vacuum, any possibility of atmospheric contamination is eliminated. Heating elements made of high-temperature materials like molybdenum or tungsten bring the parts to temperature, resulting in an exceptionally clean, bright, and oxidation-free finish.

Understanding the Trade-offs

The choice of furnace technology involves balancing cost, complexity, and the required material outcome. There is no single "best" furnace, only the right one for a specific application.

Purity vs. Cost

A vacuum furnace offers the ultimate in purity, making it essential for critical components in the aerospace, medical, and electronics industries. However, the complexity of creating and maintaining a high-quality vacuum makes these systems significantly more expensive to purchase and operate.

An inert atmosphere furnace provides excellent protection against oxidation for a much lower cost and is perfectly suitable for a vast range of industrial applications, from automotive parts to structural steel.

Speed vs. Throughput

Induction heating is unmatched for speed and precision on a part-by-part basis. It is ideal for automated production lines where specific zones of a component need to be hardened rapidly.

Conversely, large batch furnaces, such as horizontal furnaces, can process hundreds or thousands of parts simultaneously in a single, longer cycle. This offers high throughput for processes like annealing or tempering where individual part speed is less critical than overall volume.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process requires matching the technology to the end-use requirement of the material.

- If your primary focus is high-volume, general-purpose enhancement: A conventional batch furnace using an inert nitrogen atmosphere offers the best balance of cost, throughput, and quality for processes like annealing and tempering.

- If your primary focus is maximum purity and a pristine surface finish: A vacuum furnace is the definitive choice, especially for reactive metals or components where any surface contamination is unacceptable.

- If your primary focus is rapid, targeted heating of specific zones: An induction furnace provides the speed and precise control necessary for high-volume manufacturing environments like the automotive industry.

Understanding these core principles of thermal and atmospheric control empowers you to select the precise method required to engineer the exact material performance you need.

Summary Table:

| Aspect | Key Details |

|---|---|

| Thermal Control | Uses heating elements or induction for precise temperature cycles, crucial for processes like annealing and quenching. |

| Atmosphere Control | Employs inert gases (e.g., nitrogen, argon) or vacuum to prevent oxidation and ensure material purity. |

| Furnace Types | Includes batch, vacuum, and induction furnaces, each suited for different throughput, purity, and speed needs. |

| Applications | Ideal for industries like aerospace, automotive, and electronics to enhance material properties. |

Ready to optimize your material performance with the right heat treatment furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need high-volume processing, maximum purity, or rapid targeted heating, we have the expertise to help. Contact us today to discuss how our furnaces can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety