At first glance, a combined furnace for debinding and sintering appears more energy-efficient because it eliminates the need to cool parts down and reheat them. However, the actual energy consumption is far more nuanced, depending heavily on furnace design, process atmosphere, and operational demands.

The decision between separate and combined furnaces is not a simple energy calculation. It is a strategic trade-off between the potential energy savings of a combined cycle and the operational flexibility, throughput, and process integrity offered by separate, specialized units.

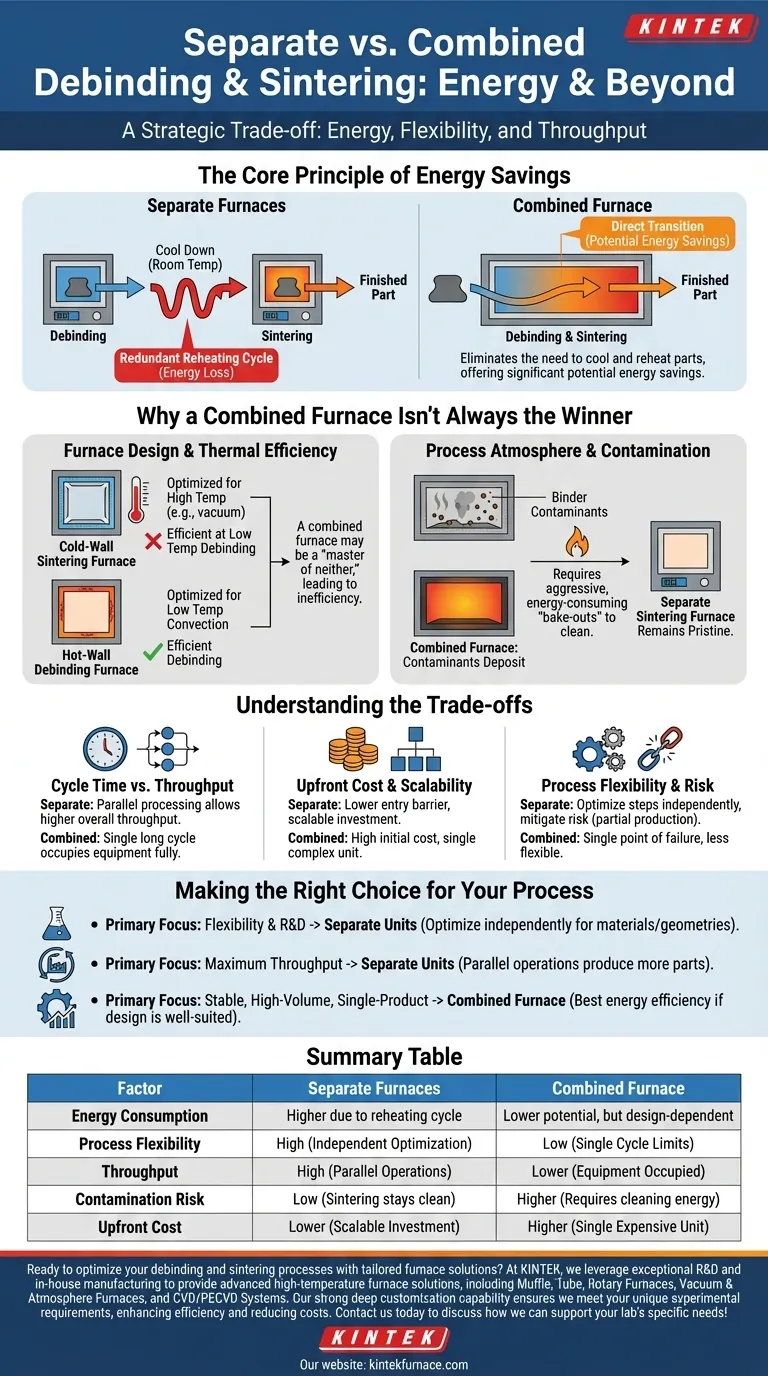

The Core Principle of Energy Savings

The primary argument for a combined debinding and sintering furnace is the avoidance of a redundant heating and cooling cycle.

Eliminating the Re-Heating Cycle

In a two-furnace setup, parts must be fully cooled after debinding before being moved and reheated from room temperature in the sintering furnace.

A combined furnace transitions directly from the lower-temperature debinding phase to the high-temperature sintering phase. This bypass of an entire thermal cycle is the single largest source of potential energy savings.

Why a Combined Furnace Isn't Always the Winner

Despite the theoretical savings, several factors can make a combined furnace less efficient or practical, sometimes consuming more energy or creating other operational costs.

Furnace Design and Thermal Efficiency

Different furnace types are optimized for different thermal processes. A furnace designed to do both may be a master of neither.

For example, many high-temperature sintering furnaces are cold-wall designs (like a graphite furnace). They are extremely efficient at reaching very high temperatures in a vacuum but are less efficient at lower-temperature, convection-heavy processes like thermal debinding.

Using such a furnace for debinding can lead to higher energy consumption than a dedicated, efficient hot-wall debinding furnace, potentially negating the savings from eliminating the re-heat cycle.

Process Atmosphere and Contamination

Debinding releases significant binder contaminants. In a combined furnace, these contaminants can deposit on the furnace's interior hot zone and insulation.

This requires aggressive cleaning cycles or "bake-outs" between runs, which consume considerable energy and time. In a separate system, the sintering furnace remains pristine, ensuring part quality and process consistency without extra energy use for cleaning.

Understanding the Trade-offs

Energy consumption is only one piece of the puzzle. A full analysis requires weighing it against other critical operational factors.

Cycle Time vs. Throughput

A combined furnace locks you into a single, long process cycle. While one batch is running, the equipment is fully occupied.

Two separate furnaces can operate in parallel. A batch can be debinding while a previous one is sintering. This can dramatically increase overall plant throughput, which is often a more significant financial driver than marginal energy savings.

Upfront Cost and Scalability

Separate furnaces offer a lower barrier to entry. A dedicated debinding furnace is generally less expensive than a high-temperature sintering furnace.

This allows you to scale your operation incrementally. You can start with one sintering furnace and multiple debinding units, adding capacity as needed without investing in another large, complex, and expensive combined machine.

Process Flexibility and Risk

Separate units provide unmatched flexibility. You can optimize the debinding cycle for one part and the sintering cycle for another without compromise.

This setup also mitigates risk. If a combined unit requires maintenance, your entire production line stops. If one of two separate furnaces goes down, you can often maintain partial production or queue parts, minimizing the impact of downtime.

Making the Right Choice for Your Process

Your decision should be guided by your primary operational goal, not just a simple energy calculation.

- If your primary focus is process flexibility and R&D: Separate units are the superior choice, allowing you to optimize each step independently for different materials and geometries.

- If your primary focus is maximum throughput: Two or more separate furnaces running in parallel will almost always produce more parts per day than a single combined unit.

- If your primary focus is a stable, high-volume, single-product line: A combined furnace can offer the best energy efficiency and lowest labor cost, provided the design is well-suited to your specific process.

By analyzing your specific production goals against these core principles, you can confidently select the most efficient and cost-effective furnace configuration for your operation.

Summary Table:

| Factor | Separate Furnaces | Combined Furnace |

|---|---|---|

| Energy Consumption | Higher due to reheating cycle | Lower potential, but depends on design |

| Process Flexibility | High, allows independent optimization | Low, single cycle limits adjustments |

| Throughput | High with parallel operations | Lower, as equipment is occupied per batch |

| Contamination Risk | Low, sintering furnace stays clean | Higher, requires energy for cleaning |

| Upfront Cost | Lower, scalable investment | Higher, single expensive unit |

Ready to optimize your debinding and sintering processes with tailored furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, enhancing efficiency and reducing costs. Contact us today to discuss how we can support your lab's specific needs!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes