The belt-type rapid sintering furnace acts as the critical activation step in the manufacturing of crystalline silicon solar cells. It subjects screen-printed metal pastes to a short-duration, high-temperature pulse, converting them into functional electrodes that can efficiently extract electricity.

The core function of this furnace is to facilitate a controlled chemical reaction where glass frit in the metal paste penetrates the solar cell's passivation layer without damaging the underlying silicon junction.

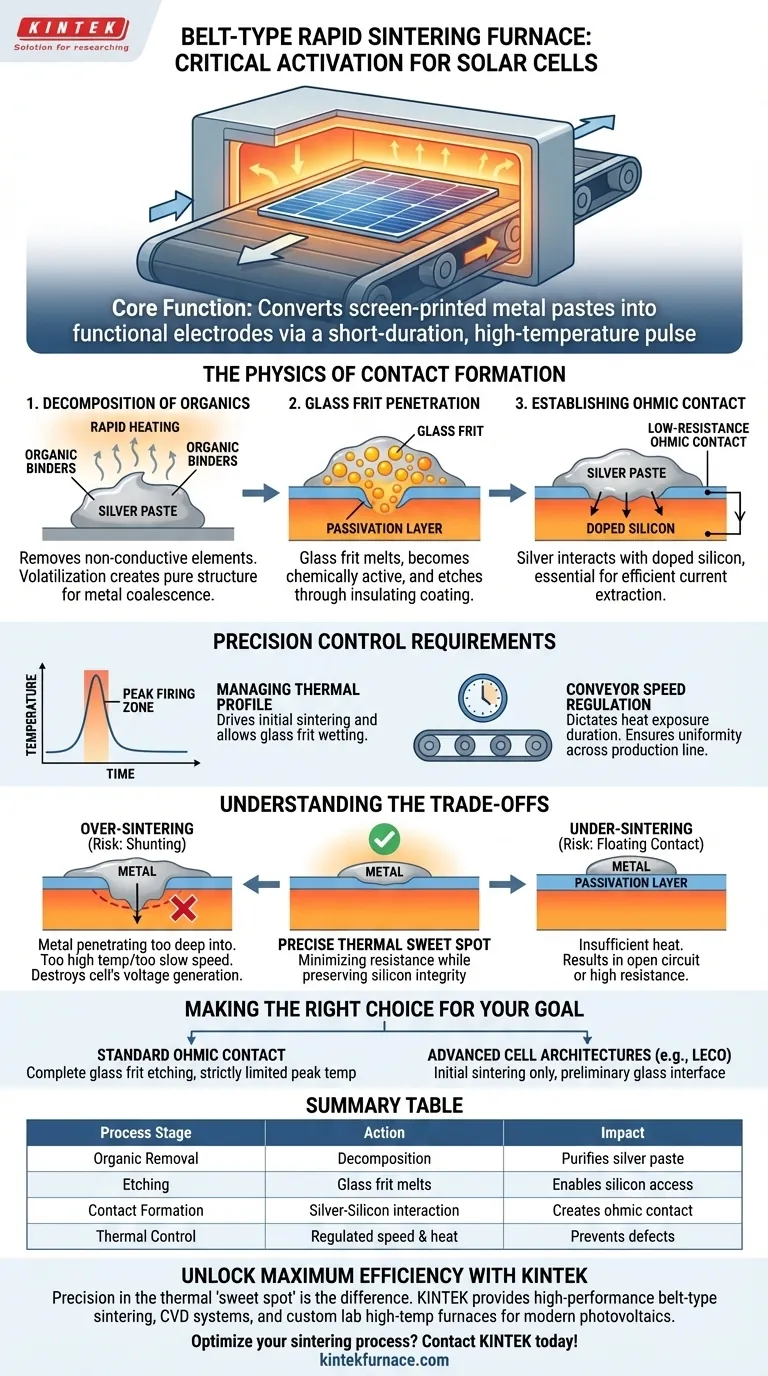

The Physics of Contact Formation

Decomposition of Organics

Before a conductive contact can form, the furnace must remove the non-conductive elements of the paste.

Rapid heating decomposes and volatilizes the organic binders and solvents present in the silver paste.

This creates a pure structure for the remaining metal particles to coalesce.

Glass Frit Penetration

The defining mechanism of this process relies on the glass frit contained within the metal paste.

Under the high-temperature pulse, this glass frit melts and becomes chemically active.

It etches through the insulating anti-reflection (passivation) coating on the surface of the cell.

Establishing Ohmic Contact

Once the passivation layer is breached, the molten silver paste interacts directly with the highly doped silicon region.

This interaction creates a low-resistance ohmic contact, which is essential for current to flow freely from the silicon into the metal grid.

Without this specific connection, the solar cell would have high series resistance and poor efficiency.

Precision Control Requirements

Managing the Thermal Profile

The furnace does not simply heat the wafer; it applies a rigorously controlled temperature profile.

This profile drives the initial sintering of silver particles and allows the glass frit to wet the silicon surface effectively.

Conveyor Speed Regulation

The "belt" aspect of the furnace dictates the duration of the heat exposure.

Precise control of the conveyor speed ensures the wafer spends the exact amount of time required in the peak firing zone.

This consistency is vital for maintaining uniformity across thousands of cells in a production line.

Understanding the Trade-offs

The Risk of Over-Sintering

The process window for rapid sintering is extremely narrow.

If the temperature is too high or the conveyor speed too slow, over-sintering occurs.

This causes the metal to penetrate too deeply, potentially shunting the p-n junction and destroying the cell's ability to generate voltage.

The Risk of Under-Sintering

Conversely, insufficient heat fails to fully etch the passivation layer.

This results in a "floating" contact where the metal sits on top of the insulator rather than connecting to the silicon.

The result is effectively an open circuit or extremely high resistance, rendering the cell useless.

Making the Right Choice for Your Goal

To maximize the effectiveness of a belt-type sintering furnace, you must align your thermal profiles with your specific cell architecture.

- If your primary focus is Standard Ohmic Contact: Prioritize a profile that ensures complete glass frit etching through the passivation layer while strictly limiting peak temperature duration to avoid junction damage.

- If your primary focus is Advanced Cell Architectures (like LECO): Adjust the furnace to achieve only "initial sintering" and a preliminary glass interface, as this provides the necessary physical foundation for subsequent Laser Enhanced Contact Optimization.

Success in sintering is defined by hitting the precise thermal "sweet spot" that minimizes resistance while preserving the structural integrity of the silicon junction.

Summary Table:

| Process Stage | Action | Impact on Solar Cell Performance |

|---|---|---|

| Organic Removal | Decomposition of binders/solvents | Purifies silver paste for metal coalescence |

| Etching | Glass frit melts & penetrates passivation | Enables access to the underlying silicon junction |

| Contact Formation | Silver-Silicon interaction | Creates low-resistance ohmic contact for current flow |

| Thermal Control | Regulated belt speed & peak heat | Prevents junction shunting and under-sintering defects |

Unlock Maximum Efficiency in Solar Cell Production

Precision in the thermal 'sweet spot' is the difference between a high-performance solar cell and a wasted wafer. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance belt-type sintering, CVD systems, and custom lab high-temp furnaces designed to meet the rigorous demands of modern photovoltaics. Whether you are perfecting standard ohmic contacts or advancing LECO architectures, our customizable solutions ensure uniform heating and precise conveyor control.

Ready to optimize your sintering process? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Hakim Korichi, Ahmed Baha-Eddine Bensdira. Investigating the influence of boron diffusion temperature on the performance of n-type PERT monofacial solar cells with reduced thermal steps. DOI: 10.35784/iapgos.6599

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the specific purpose of using a laboratory oven for the treatment of copper oxide precipitates? Expert Insights

- Why is a high-precision constant temperature drying oven required for biochar? Protect Delicate Pore Structures

- Why pre-treat nanopowders in an industrial oven? Optimize Epoxy Nanocomposite Strength and Consistency

- What is the purpose of using a laboratory blast drying oven at 107°C for 17 hours for reforming catalysts?

- What is the function of a constant temperature blast drying oven? Achieve Uniform Chemical Activation and Porosity

- What is the function of a laboratory drying oven in the preparation of solid bismuth molybdate materials? Expert Tips

- What role does a Teflon-lined stainless steel autoclave play in the hydrothermal synthesis of PtLaOx@S-1 catalysts?

- What are the primary purposes of using high-purity argon flow during the pyrolysis of CMS membranes? Achieve High-Purity Results