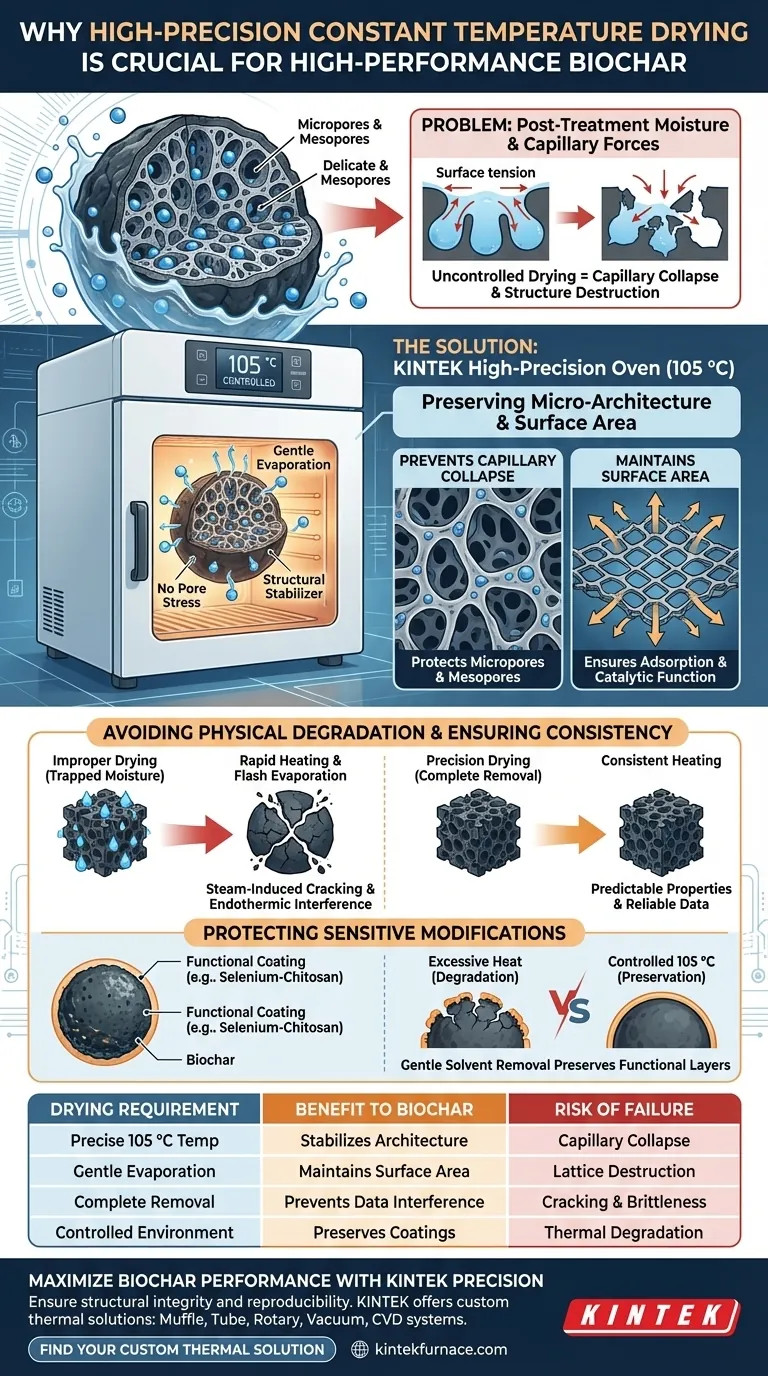

A high-precision constant temperature drying oven is essential for preserving the structural integrity of high-performance biochar. After the removal of residual salts via acid washing and rinsing, this equipment allows for the thorough removal of moisture at a controlled 105 °C. This precise drying step is the only way to prevent residual water from exerting capillary forces that would otherwise cause the delicate pore structure to collapse.

The oven is not merely a drying tool; it is a structural stabilizer. Its primary function is to eliminate moisture gently to ensure the biochar retains its highly developed microporous and mesoporous architecture.

Preserving Micro-Architecture

Preventing Capillary Collapse

The most critical function of the drying oven is the protection of the biochar's internal lattice. When biochar is washed, water fills its pores.

If this water is not removed under controlled conditions, the surface tension creates strong capillary forces. These forces can crush the pore walls, destroying the microporous and mesoporous structure that defines high-performance biochar.

Maintaining Surface Area

High-performance biochar, such as that derived from chitin, relies on a vast surface area for its effectiveness.

By maintaining a constant temperature of 105 °C, the oven ensures water evaporates at a rate that does not stress the carbon skeleton. This preserves the open pore network required for adsorption and catalytic applications.

Avoiding Physical Degradation

Eliminating Steam-Induced Cracking

Beyond capillary forces, uncontrolled moisture presents a risk during any subsequent high-temperature processing.

If moisture remains trapped inside the biomass or biochar, rapid heating can cause flash evaporation. This rapid steam release generates internal pressure that leads to structural cracking and irregular collapse of the material.

Ensuring Material Stability

Consistent drying prevents physical deformities in the final product.

Whether treating coconut husk or Rosa roxburghii residue, complete moisture removal prevents the material from becoming brittle or physically unstable. This ensures the physical properties of the carbon remain predictable and robust.

Understanding the Risks of Improper Drying

The Risk of Endothermic Interference

Failing to remove all physically adsorbed moisture introduces significant experimental variables.

Residual water acts as a heat sink, creating endothermic effects that absorb energy during later heating stages. This interferes with combustion temperature stability and compromises the reproducibility of your data.

Degradation of Modified Surfaces

For biochar modified with functional layers, such as selenium-chitosan, temperature precision is non-negotiable.

Excessive heat during drying can degrade these sensitive surface modifications. A high-precision oven allows for gentle solvent removal, preserving the functional properties that are often chemically fragile.

Ensuring Quality in Biochar Production

To maximize the performance of your biochar, you must match your drying strategy to your material goals.

- If your primary focus is Surface Area: Prioritize steady drying at 105 °C to prevent capillary forces from collapsing micropores and mesopores.

- If your primary focus is Surface Chemistry: Ensure the temperature is low enough to remove solvents without degrading sensitive functional coatings like chitosan.

- If your primary focus is Process Consistency: Remove 100% of adsorbed moisture to prevent endothermic reactions from skewing your thermal data.

Precision in drying is the invisible step that secures the visible quality of the final carbon material.

Summary Table:

| Drying Requirement | Benefit to Biochar | Risk of Failure |

|---|---|---|

| Precise 105 °C Temp | Stabilizes microporous/mesoporous architecture | Capillary forces cause pore wall collapse |

| Gentle Evaporation | Maintains maximum specific surface area | Surface tension crushes internal lattice |

| Complete Moisture Removal | Prevents endothermic interference in data | Steam-induced cracking and material brittleness |

| Controlled Environment | Preserves sensitive functional surface layers | Thermal degradation of modified coatings |

Maximize Your Biochar Performance with KINTEK Precision

Don't let improper drying compromise your material's structural integrity. Backed by expert R&D and manufacturing, KINTEK offers high-precision drying ovens and advanced thermal systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab requirements. Whether you are working with biomass residues or sensitive functional coatings, our equipment ensures the stability and reproducibility your research demands.

Ready to elevate your biochar production? Contact us today to find your custom thermal solution!

Visual Guide

References

- Pu Yang, Feng Jiang. Phase Diagram‐Guided Molten Salt Engineering of Biocarbon Pores at Low Temperatures. DOI: 10.1002/smll.202501162

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the requirements for synthesizing Magnesium alloys via ampoule method? Expert Synthesis Protocols

- What are the technical advantages of using high-purity hydrogen as a protective atmosphere? Boost Heat Treatment Speed

- How does the temperature capability of continuous furnaces benefit industrial processes? Boost High-Volume Production with Extreme Heat

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance

- Why are industrial-grade drying and crushing equipment necessary for pretreatment? Optimize Chemical Reactions

- What is the purpose of a safety warning system in MDR? Ensure Reactor Integrity and Laboratory Safety

- What is the function of the electric arc furnace in the production of UMG-Si? Powering Silicon Transformation