The primary purpose of an automatic shut-off system in Methane Dry Reforming (MDR) is to act as a fail-safe against catastrophic reactor rupture caused by internal blockages. By strictly monitoring pressure limits and flow rates, the system detects the early signs of obstruction—often caused by carbon buildup—and immediately terminates the reaction by cutting off heat and gas supplies to preserve the equipment.

Methane Dry Reforming operates at extreme temperatures where internal obstructions are a persistent risk. An automated safety system provides the necessary response speed to neutralize the reaction before pressure accumulation destroys the reactor or endangers the laboratory environment.

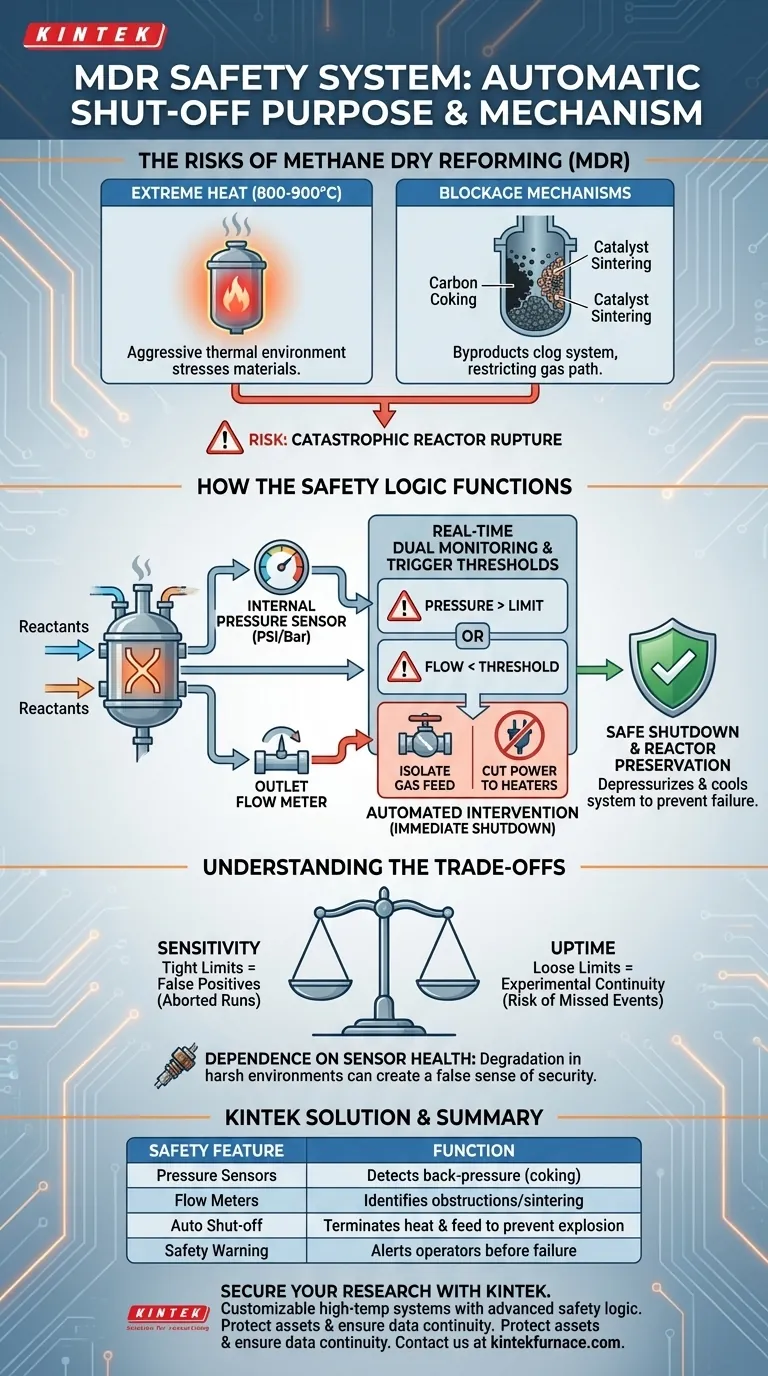

The Unique Risks of Methane Dry Reforming

Extreme Operating Temperatures

MDR reactions require an aggressive thermal environment, typically operating between 800 °C and 900 °C.

At these temperatures, the structural integrity of reactor materials is already under significant stress. This makes the margin for error regarding pressure containment much smaller than in low-temperature processes.

The Mechanism of Blockage

The chemical nature of MDR frequently leads to physical byproducts that can clog the system.

The two primary culprits are carbon deposition (often called coking) and catalyst sintering. As these materials accumulate or fuse, they restrict the gas path, turning the reactor into a potential pressure vessel.

How the Safety Logic Functions

Real-Time Dual Monitoring

Reliable safety systems do not rely on a single data point. Instead, they monitor two correlated variables: internal pressure sensors and outlet flow meters.

This dual-input approach helps verify that a pressure spike is actually due to a blockage (indicated by a simultaneous drop in flow) rather than a sensor error.

The Trigger Thresholds

The system is programmed with strict operational boundaries.

An emergency sequence is initiated if the internal pressure exceeds a pre-set safety limit or if the outlet flow drops below a minimum threshold. These deviations are the signature of a developing blockage.

Automated Intervention

Speed is critical when dealing with high-pressure gas at 900 °C.

Upon detecting a breach of threshold, the system triggers an immediate emergency shutdown. This action simultaneously isolates the gas feed and cuts power to the heating elements, rapidly depressurizing and cooling the system to prevent failure.

Understanding the Trade-offs

Sensitivity vs. Uptime

There is an inherent trade-off between safety and experimental continuity.

If the safety thresholds are set too tightly, the system may trigger false positives due to minor, non-critical fluctuations. This results in aborted runs, wasted reactants, and lost data.

Dependence on Sensor Health

The safety system is only as reliable as its sensors.

In harsh MDR environments, sensors can degrade or become coated in carbon. If a sensor fails or drifts, the automated system may fail to detect a genuine emergency, creating a false sense of security for the operator.

Making the Right Choice for Your Goal

When configuring your safety parameters, align them with your specific operational priorities:

- If your primary focus is Asset Protection: Set your pressure cutoff limits significantly below the reactor's maximum rating to prevent cumulative stress fatigue on the vessel.

- If your primary focus is Data Continuity: Utilize high-precision flow meters and time-delay triggers (e.g., pressure must stay high for 5 seconds) to filter out transient noise and avoid unnecessary shutdowns.

Integrating this automated defense layer is the most effective method to ensure that the predictable chemical instability of MDR does not result in physical destruction.

Summary Table:

| Safety Feature | Monitoring Parameter | Function in MDR Reaction |

|---|---|---|

| Pressure Sensors | Internal PSI/Bar | Detects back-pressure from carbon deposition (coking). |

| Flow Meters | Outlet Gas Flow | Identifies physical obstructions or catalyst sintering. |

| Auto Shut-off | Power & Gas Feed | Immediately terminates heat and feed to prevent explosion. |

| Safety Warning | Visual/Audible Alerts | Notifies operators of deviations before critical failure. |

Secure Your High-Temperature Research with KINTEK

Don’t let carbon buildup compromise your laboratory safety. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to withstand the rigors of Methane Dry Reforming. Our lab high-temp furnaces are fully customizable, featuring advanced safety monitoring and automatic shut-off logic tailored to your unique experimental needs.

Ready to upgrade your reactor safety? Contact us today to consult with our engineering team." Form) and discover how our specialized heating solutions can protect your assets and ensure data continuity."

Visual Guide

References

- Kyung Hee Oh, Ji Chan Park. Scalable Exsolution‐Derived E‐Ni/m‐MgAlO <sub>x</sub> Catalysts with Anti‐Sintering Stability for Methane Dry Reforming. DOI: 10.1002/smll.202508028

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a vacuum system composed of molecular and mechanical pumps essential? Ensure Purity in Magnetron Sputtering

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- Why is a vacuum drying oven necessary for MPCF@VG@SiNDs/C granulation? Ensure Framework Stability and Prevent Oxidation

- What role does a pyrolysis furnace play in preparing graphene nanosheets? Master High-Value Plastic Transformation

- What are the temperature ranges for low, medium, and high-temperature industrial heating processes? Optimize Your Process with KINTEK

- What is preventive maintenance on a furnace? A Proactive Strategy for Peak Performance

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation