Precision drying is the absolute baseline for experimental accuracy. You must use a precision oven to treat moxa floss samples to a unified air-drying basis to standardize their moisture content prior to testing. This specific treatment removes surface moisture variations caused by the environment, ensuring every sample begins from an identical physical state.

Scientific rigor requires isolating the variable you intend to study. By standardizing moisture content through precision drying, you eliminate environmental noise, ensuring that observed differences in combustion performance are due to the moxa floss itself, not random fluctuations in humidity.

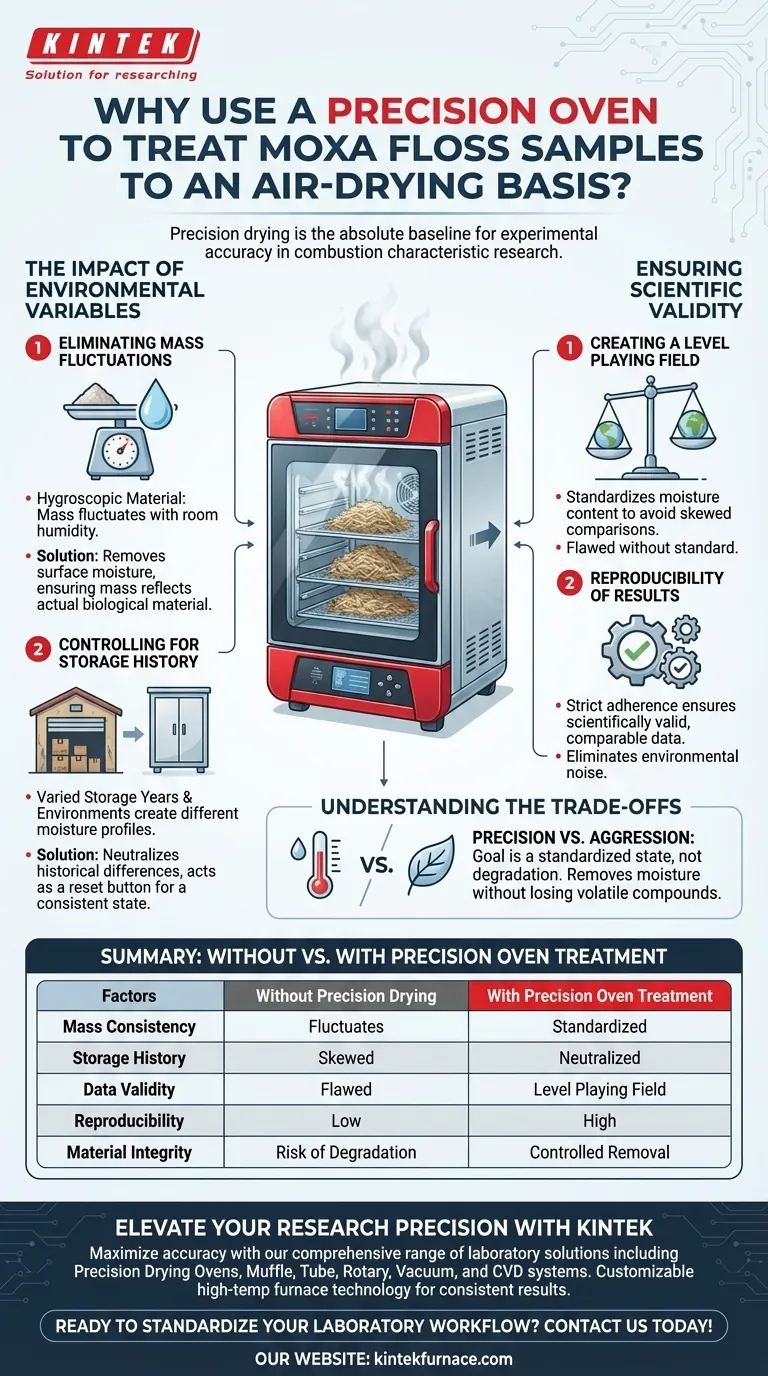

The Impact of Environmental Variables

Eliminating Mass Fluctuations

Moxa floss is a hygroscopic material, meaning it readily absorbs moisture from the surrounding air. If left untreated, the mass of the sample will fluctuate based on the specific humidity of the laboratory or storage facility.

Using a precision oven removes this variable surface moisture. This ensures that the weight measurements you record reflect the actual biological material, not the water it has absorbed from the room.

Controlling for Storage History

Samples often come from different "storage years" or distinct environments. A sample stored in a humid warehouse for three years will have a vastly different moisture profile than fresh stock stored in a dry cabinet.

Precision drying neutralizes these historical differences. It acts as a reset button, bringing all samples—regardless of their age or storage background—to a consistent initial state.

Ensuring Scientific Validity

Creating a Level Playing Field

In combustion characteristic research, you are often comparing samples from various "geographical origins." Without a unified air-drying standard, these comparisons are fundamentally flawed.

If Sample A is wetter than Sample B simply because of where it was grown or stored, your combustion data will be skewed. The oven treatment ensures that the playing field is level for all batches.

Reproducibility of Results

The goal of any scientific study is to produce data that is comparable and reproducible. Standardization is the mechanism that achieves this.

By strictly adhering to an air-drying basis, you ensure that your experimental results are scientifically valid. This allows other researchers to verify your findings without wondering if humidity played a role in the outcome.

Understanding the Trade-offs

Precision vs. Aggression

While removing surface moisture is critical, it is important to distinguish between "air-drying basis" and "absolute drying" (bone dry).

The goal is to reach a standardized state, not to degrade the material. Using a precision oven is necessary to maintain specific temperatures that remove moisture without triggering premature pyrolysis or losing volatile compounds that are essential to the combustion profile.

Making the Right Choice for Your Research

To ensure your combustion characteristic research is robust, apply the following principles to your sample preparation:

- If your primary focus is comparative analysis: Prioritize strict adherence to the unified air-drying standard to ensure samples from different origins are statistically comparable.

- If your primary focus is data integrity: Use the precision oven to eliminate mass fluctuations, documenting the exact parameters used to guarantee reproducibility.

Standardization is not just a step in the process; it is the foundation of credible data.

Summary Table:

| Factor | Without Precision Drying | With Precision Oven Treatment |

|---|---|---|

| Mass Consistency | Fluctuates based on room humidity | Standardized biological mass |

| Storage History | Skewed by age and environment | Neutralized to a consistent state |

| Data Validity | Flawed comparisons between origins | Level playing field for all samples |

| Reproducibility | Low; environmental noise interference | High; verifiable scientific results |

| Material Integrity | Risk of degradation or dampness | Controlled moisture removal |

Elevate Your Research Precision with KINTEK

Maximize the accuracy of your combustion characteristic research by starting with a perfectly standardized sample. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside our precision drying ovens—all customizable to your unique experimental needs. Whether you are treating moxa floss or advanced materials, our high-temp furnace technology ensures consistent results every time.

Ready to standardize your laboratory workflow? Contact us today to find your custom solution!

Visual Guide

References

- Yukun Feng, Zhaoyi Zhuang. Combustion Characteristics of Moxa Floss Under Nitrogen Atmosphere. DOI: 10.3390/fuels6020048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of post-treating Nitrogen-doped Carbide-Derived Carbon (N-CDC)? Optimize Purity & Performance

- What are the ideal characteristics of a quenching medium? Achieve Optimal Hardness and Safety in Heat Treatment

- What is the purpose of using a vacuum dryer for PU and AlN composite sheets? Enhance Thermal & Structural Integrity

- What is the role of a laboratory vacuum drying oven in LNMO electrode slurry preparation? Master Solvent Removal

- Why is high-purity argon gas required during the calcination of TiO2/MoSe2 materials? Protect Your Sensor's Integrity

- How is a precision micro-Raman spectrometer utilized in the characterization of SSBSN ceramics? Master Phase Verification

- What physical characteristics of high-precision heating equipment are used in CSE selenium recycling?

- What role does Iodine (I2) play as a transport agent in CVT for FexTaSe2? Unlock Efficient Single Crystal Growth