The ideal quenching medium is defined by four key characteristics: a specific cooling profile to achieve desired hardness without causing defects, long-term stability for consistent results, operational safety and environmental friendliness, and overall cost-effectiveness. In essence, it must cool the workpiece rapidly at high temperatures but slowly once the metal enters its critical transformation range to prevent cracking and distortion.

The concept of a single "ideal" quenchant is a theoretical benchmark. In practice, the optimal choice is always a strategic trade-off, balancing the metallurgical goal of hardness against the practical necessities of dimensional stability, safety, and cost.

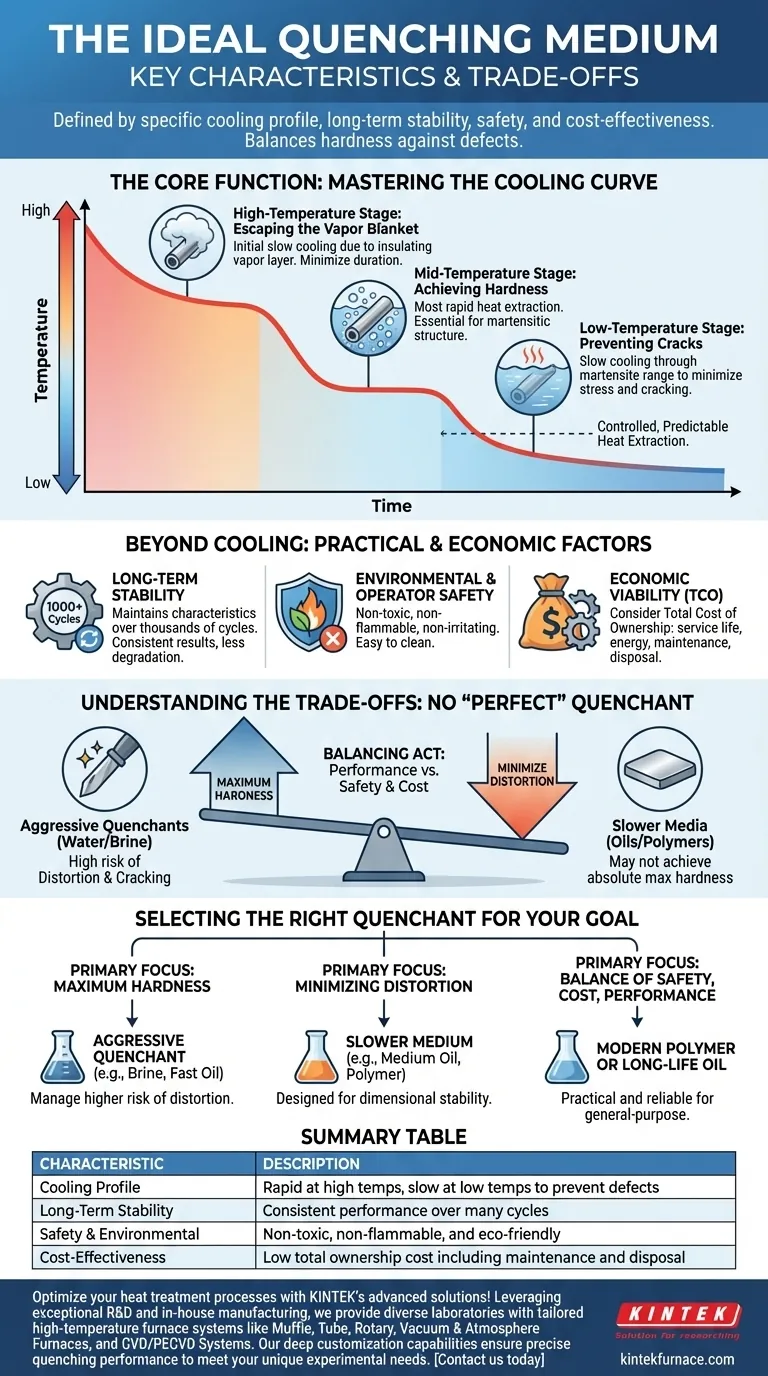

The Core Function: Mastering the Cooling Curve

The most critical characteristic of any quenching medium is its ability to extract heat from a workpiece in a controlled, predictable manner. This process is not linear and can be broken down into three distinct stages.

High-Temperature Stage: Escaping the Vapor Blanket

When a hot part first enters the quenchant, a layer of vapor called a vapor blanket instantly forms around it. This blanket acts as an insulator, dramatically slowing down the initial cooling rate. An ideal medium minimizes the duration and stability of this phase to begin effective cooling as quickly as possible.

Mid-Temperature Stage: Achieving Hardness

Once the vapor blanket collapses, the quenchant enters the nucleate boiling phase. This is where the most rapid heat extraction occurs as liquid boils violently at the workpiece's surface. A fast cooling rate in this stage is essential for preventing the formation of soft microstructures (like pearlite) and achieving the desired hardened martensitic structure.

Low-Temperature Stage: Preventing Cracks

As the part cools further, it enters the convective cooling stage. Here, boiling ceases, and heat is removed more slowly via convection. It is crucial for the cooling rate to be slow in this range, especially as the steel passes through its martensite start (Ms) and finish (Mf) temperatures. Slowing down here reduces thermal stress, minimizing the risk of distortion and quench cracking.

Beyond Cooling: Practical and Economic Factors

While the cooling curve dictates the metallurgical outcome, several other factors determine a quenchant's real-world viability and reliability.

Long-Term Stability and Consistency

An effective medium must maintain its cooling characteristics over thousands of cycles. Degradation due to heat or contamination leads to inconsistent results, causing unpredictable workpiece quality and requiring costly process adjustments. Stability ensures that the 1000th part is quenched identically to the first.

Environmental and Operator Safety

Modern manufacturing places a high premium on safety. An ideal medium is non-toxic, non-flammable, and non-irritating to operators. It should not produce hazardous fumes and should be easy to clean from parts without requiring harsh chemicals.

Economic Viability (Total Cost of Ownership)

The initial purchase price is only one part of the equation. A truly cost-effective quenchant considers the total cost of ownership, which includes its service life, maintenance requirements, energy consumption for heating or cooling, and disposal costs.

Understanding the Trade-offs: No "Perfect" Quenchant

Every quenching medium represents a compromise. Understanding these trade-offs is key to making an informed decision.

Hardness vs. Distortion

This is the fundamental metallurgical trade-off. Aggressive quenchants like water or brine provide extremely fast cooling for maximum hardness but generate immense internal stresses, leading to a high risk of warping and cracking. Slower media, like oils, are gentler on the part but may not achieve the absolute maximum hardness.

Performance vs. Safety and Cost

Water is cheap, non-flammable, and effective, but its cooling curve is often too aggressive and difficult to control. Traditional oils offer excellent control but introduce fire hazards and fumes. Modern polymer quenchants bridge this gap, offering adjustable cooling rates and enhanced safety, but they can be more expensive and require tighter concentration control.

Selecting the Right Quenchant for Your Goal

Your choice must be driven by the primary objective for your specific workpiece.

- If your primary focus is Maximum Hardness: Select an aggressive quenchant like brine or a fast-formulated oil, but be prepared to manage a higher risk of distortion.

- If your primary focus is Minimizing Distortion: Choose a slower, more controlled medium like a medium-speed quenching oil or a polymer quenchant designed for dimensional stability.

- If your primary focus is a Balance of Safety, Cost, and Performance: Modern polymer quenchants or high-quality, long-life quenching oils are often the most practical and reliable choices for general-purpose heat treating.

Ultimately, choosing the right quenching medium is about matching the tool to the specific metallurgical task at hand.

Summary Table:

| Characteristic | Description |

|---|---|

| Cooling Profile | Rapid at high temps, slow at low temps to prevent defects |

| Long-Term Stability | Consistent performance over many cycles |

| Safety & Environmental | Non-toxic, non-flammable, and eco-friendly |

| Cost-Effectiveness | Low total ownership cost including maintenance and disposal |

Optimize your heat treatment processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise quenching performance to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production