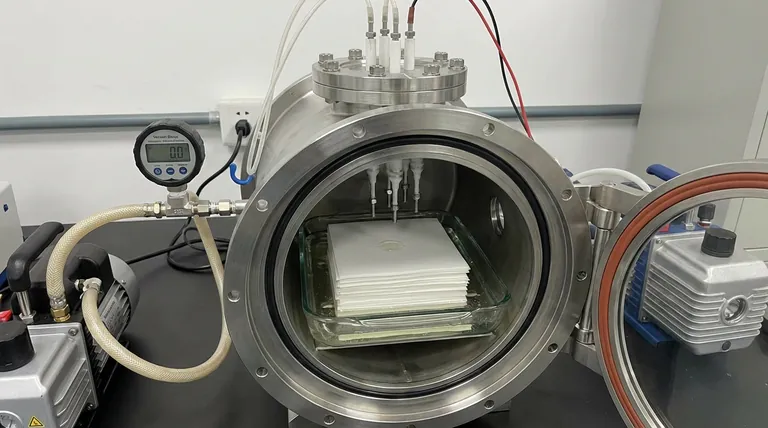

The primary purpose of using a vacuum dryer during the resin impregnation phase is to create a negative pressure environment that forcibly evacuates air trapped within the Aluminum Nitride (AlN) fiber skeletons. This evacuation is critical because it removes the air resistance that would otherwise prevent the low-viscosity Polyurethane (PU) solution from entering the microscopic gaps of the material.

By eliminating air pockets within the fiber network, vacuum drying ensures complete resin infiltration and tight interfacial contact between the inorganic AlN filler and the organic PU matrix. This structural integrity is the prerequisite for achieving high thermal conductivity and reliable electrical insulation.

The Mechanics of Vacuum Impregnation

Evacuating the Microstructure

The Aluminum Nitride (AlN) framework consists of a complex, three-dimensional nanofiber network. Under normal atmospheric pressure, air is trapped deep within the micropores of this skeleton.

Using a vacuum dryer creates a negative pressure environment. This physically pulls the air out of these voids, leaving empty space that is ready to be filled.

Enabling Deep Penetration

Once the air is evacuated, the barrier to fluid entry is removed. This allows the low-viscosity Polyurethane (PU) solution to flow freely into the intricacies of the AlN network.

Without the vacuum, the resin would likely coat only the surface, leaving the internal structure dry and structurally weak.

Critical Impact on Material Performance

Maximizing Interfacial Contact

The ultimate goal of this composite is to marry the properties of the ceramic filler with the polymer matrix. The vacuum process ensures tight interfacial contact between the inorganic AlN and the organic PU.

This continuous interface is vital for the transfer of energy across the material.

Boosting Thermal and Electrical Properties

Gaps or air pockets act as insulators for heat, drastically lowering thermal conductivity. By ensuring the PU completely fills the AlN network, the vacuum process creates a direct path for heat dissipation.

Simultaneously, a void-free structure ensures superior electrical insulation, preventing breakdown that can occur in air-filled cavities.

Preventing Defects and Common Pitfalls

Eliminating Internal Voids

Beyond just moving resin, the vacuum environment manages the quality of the cure. It assists in the migration of residual water and trace solvents out of the material.

If these volatiles are not removed via vacuum negative pressure, they can become trapped as the film forms. This leads to internal bubbles, pinholes, or structural defects that compromise the sheet.

Reducing Internal Stress

The controlled environment of a vacuum dryer does more than just fill holes; it aids in the orderly rearrangement of polymer chains.

By preventing rapid or uneven drying, the process minimizes internal stress. This results in a composite sheet with higher mechanical strength and greater structural density.

Making the Right Choice for Your Goal

To ensure you are utilizing the vacuum dryer effectively for your specific requirements:

- If your primary focus is Thermal Conductivity: Ensure the vacuum level is sufficient to evacuate the smallest micropores, as air pockets are the primary barrier to heat transfer.

- If your primary focus is Mechanical Longevity: Monitor the process to ensure all trace solvents and moisture are evacuated, preventing internal stress and pinhole formation.

The vacuum dryer is not merely a drying tool; it is the fundamental mechanism that transforms a loose fiber network and liquid resin into a high-performance, unified composite material.

Summary Table:

| Feature | Impact of Vacuum Impregnation | Benefit for Composite Material |

|---|---|---|

| Air Removal | Evacuates air from AlN nanofiber skeletons | Eliminates resistance for resin entry |

| Resin Penetration | Allows low-viscosity PU to fill micropores | Ensures complete infiltration and density |

| Interface Quality | Creates tight contact between AlN and PU | Maximizes thermal conductivity and insulation |

| Defect Control | Removes trace solvents and moisture | Prevents internal bubbles and pinholes |

| Structural Stress | Facilitates orderly polymer rearrangement | Increases mechanical strength and longevity |

Elevate Your Material Research with KINTEK

Achieving the perfect composite requires precision-engineered thermal and vacuum environments. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Systems, Muffle, Tube, Rotary, and CVD furnaces, all customizable to meet your unique laboratory needs. Whether you are optimizing thermal conductivity in AlN-PU sheets or developing next-generation insulators, our equipment ensures consistent, void-free results.

Ready to enhance your lab's efficiency? Contact us today to discuss your custom furnace solution.

References

- Md. Shakhawat Hossain, Koji Nakane. Enhancing heat dissipation in polyurethane sheets through the incorporation of freeze‐dried aluminum nitride nanofiber. DOI: 10.1111/ijac.14725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why introduce high-purity N2 during cooling after roasting? Preserve Sample Integrity and Prevent Oxidation

- What key process environments does a Molecular Beam Epitaxy (MBE) system provide? Optimize CaF2 Thin Film Growth

- Why is immediate quenching required after CTS treatment of mesoporous carbon? Preserve Your Material’s Atomic Structure

- Why is long-term NaOH immersion required for porous carbon? Optimize Your Template Removal & Surface Area

- What advantages does a vacuum drying oven offer? Superior Chemical Stability & Efficient Dehydration

- What type of reaction environment is required for the synthesis of Ge-Se-Tl-Sb chalcogenide glasses? | KINTEK

- Why is temperature control accuracy critical for K439B superalloy? Master 1160°C Solution Treatment

- What role do high-temperature industrial furnaces play in the pretreatment of spodumene for lithium extraction?