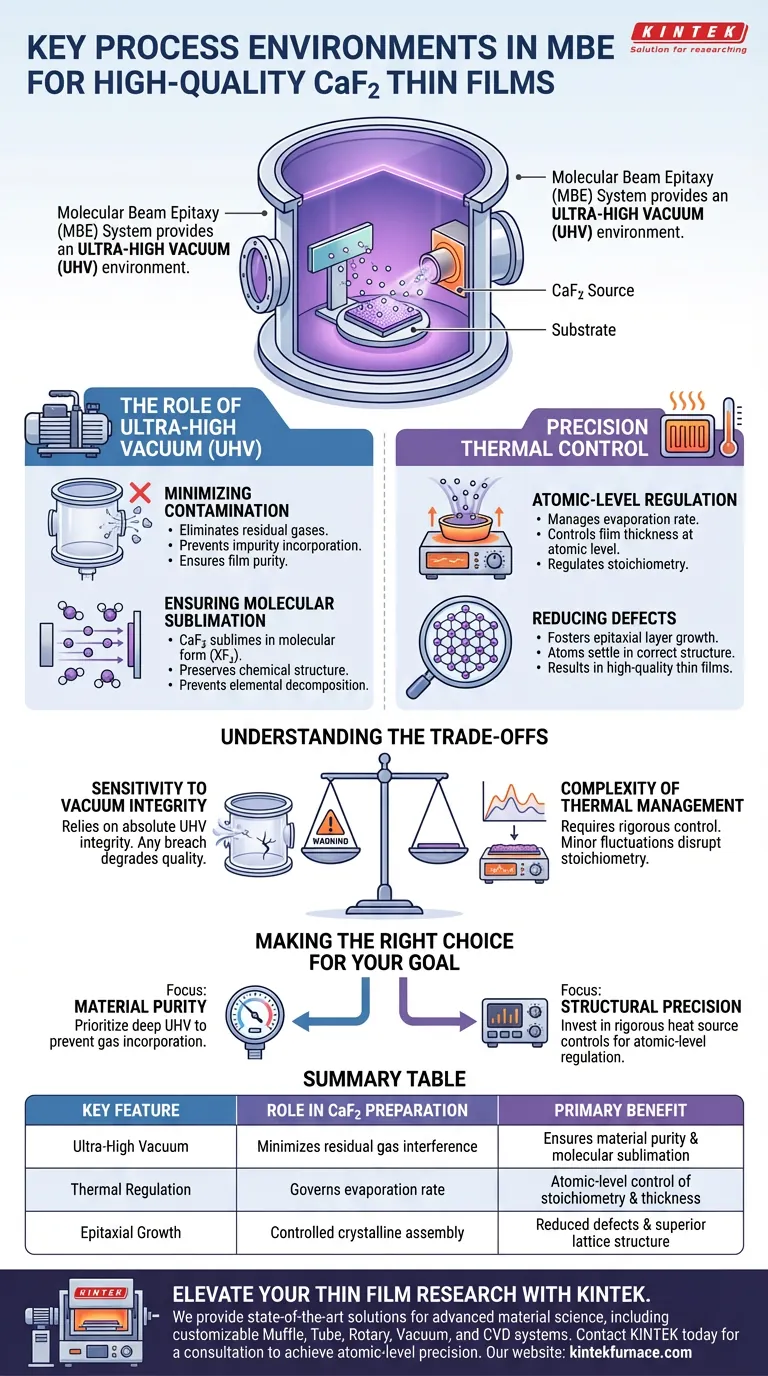

A Molecular Beam Epitaxy (MBE) system primarily provides an Ultra-High Vacuum (UHV) environment essential for preparing high-quality Calcium Fluoride (CaF2) thin films. By maintaining this vacuum, the system minimizes interference from residual gases and allows CaF2 to sublime and deposit in its molecular form, while precise heat controls enable atomic-level regulation of film thickness.

The combination of an Ultra-High Vacuum (UHV) and precise thermal regulation is critical for growing defect-free CaF2 layers. This environment ensures the material deposits in its correct molecular form without contamination, allowing for exact control over stoichiometry and thickness.

The Role of Ultra-High Vacuum (UHV)

Minimizing Contamination

The MBE system creates a pristine environment that significantly reduces the presence of residual gases. This absence of background gas is crucial because it prevents impurities from incorporating into the growing crystal lattice. By eliminating these interferences, the system ensures the purity of the Calcium Fluoride thin films.

Ensuring Molecular Sublimation

Within this UHV environment, Calcium Fluoride behaves differently than it would under standard atmospheric conditions. It sublimes and deposits in its specific molecular form (XF2) rather than decomposing into separate elements. This preservation of the molecular structure during transport is vital for maintaining the correct chemical balance in the final film.

Precision Thermal Control

Atomic-Level Regulation

The system utilizes precise heat source controls to strictly manage the rate of evaporation. This control mechanism allows for the regulation of film thickness and stoichiometry at the atomic level.

Reducing Defects

By coupling thermal precision with a clean vacuum, the system fosters the growth of epitaxial layers with minimal defects. The controlled environment ensures that the atoms settle into the correct crystalline structure, resulting in high-quality thin films.

Understanding the Trade-offs

Sensitivity to Vacuum Integrity

The primary limitation of this process is its absolute reliance on the integrity of the UHV environment. Any breach in vacuum or rise in pressure reintroduces residual gases, which immediately interferes with the molecular deposition and degrades film quality.

Complexity of Thermal Management

Achieving perfect stoichiometry requires rigorous and constant control over the heat source. Minor fluctuations in temperature can disrupt the sublimation rate of the CaF2, leading to inconsistencies in film thickness or structural defects.

Making the Right Choice for Your Goal

To achieve high-quality epitaxial growth, you must prioritize environmental stability.

- If your primary focus is material purity: Ensure your system can maintain deep UHV levels to prevent residual gas incorporation and interference.

- If your primary focus is structural precision: Invest in rigorous heat source controls to govern the atomic-level thickness and stoichiometry of the film.

By strictly controlling the vacuum and thermal environment, MBE transforms Calcium Fluoride growth from a variable process into a precise molecular assembly.

Summary Table:

| Key Feature | Role in CaF2 Preparation | Primary Benefit |

|---|---|---|

| Ultra-High Vacuum | Minimizes residual gas interference | Ensures material purity & molecular sublimation |

| Thermal Regulation | Governs evaporation rate | Atomic-level control of stoichiometry & thickness |

| Epitaxial Growth | Controlled crystalline assembly | Reduced defects & superior lattice structure |

Elevate Your Thin Film Research with KINTEK

High-quality epitaxial growth demands more than just standard equipment—it requires the precision of a master-crafted thermal and vacuum environment. KINTEK provides state-of-the-art laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of advanced material science.

Whether you are refining CaF2 stoichiometry or developing next-generation semiconductor layers, our expert R&D and manufacturing teams offer customizable systems tailored to your unique research needs.

Ready to achieve atomic-level precision? Contact KINTEK today for a customized consultation and see how our high-temperature furnace technology can transform your thin film production.

Visual Guide

References

- Thin Fluoride Insulators for Improved 2D Transistors: From Deposition Methods to Recent Applications. DOI: 10.1002/pssr.202500200

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why use nitrogen and flow meters in sludge pyrolysis? Ensuring Superior Biochar Quality and Anaerobic Integrity

- What are the benefits of using advanced technology in heat treatment furnaces? Achieve Superior Material Quality and Efficiency

- How does a high-temperature sintering furnace influence ZnO nanotube sensors? Unlock Peak Sensitivity and Stability

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- What is the purpose of introducing high-purity argon gas into an immersed probe? Enhance Melt Analysis Accuracy

- Why is a slow heating rate utilized for rice husk biochar? Optimize Pore Structure and Adsorption Performance

- Why is a constant temperature drying oven required for processing lignin residue? Ensure Superior Pore Dehydration

- What are the functions of an industrial drying furnace vertically installed below a shredder? Efficient LIB Recycling