In short, advanced technology in heat treatment furnaces delivers superior material quality, exceptional process consistency, and greater operational efficiency. By leveraging precise control over temperature and atmosphere, these systems prevent common defects like oxidation, ensure uniform material properties, and significantly reduce the consumption of process utilities, leading to long-term cost savings.

The fundamental shift is from heat treatment as a brute-force process to a highly controlled, scientific method. Advanced furnaces act less like ovens and more like precision instruments, giving you direct control over the final metallurgy and finish of your components.

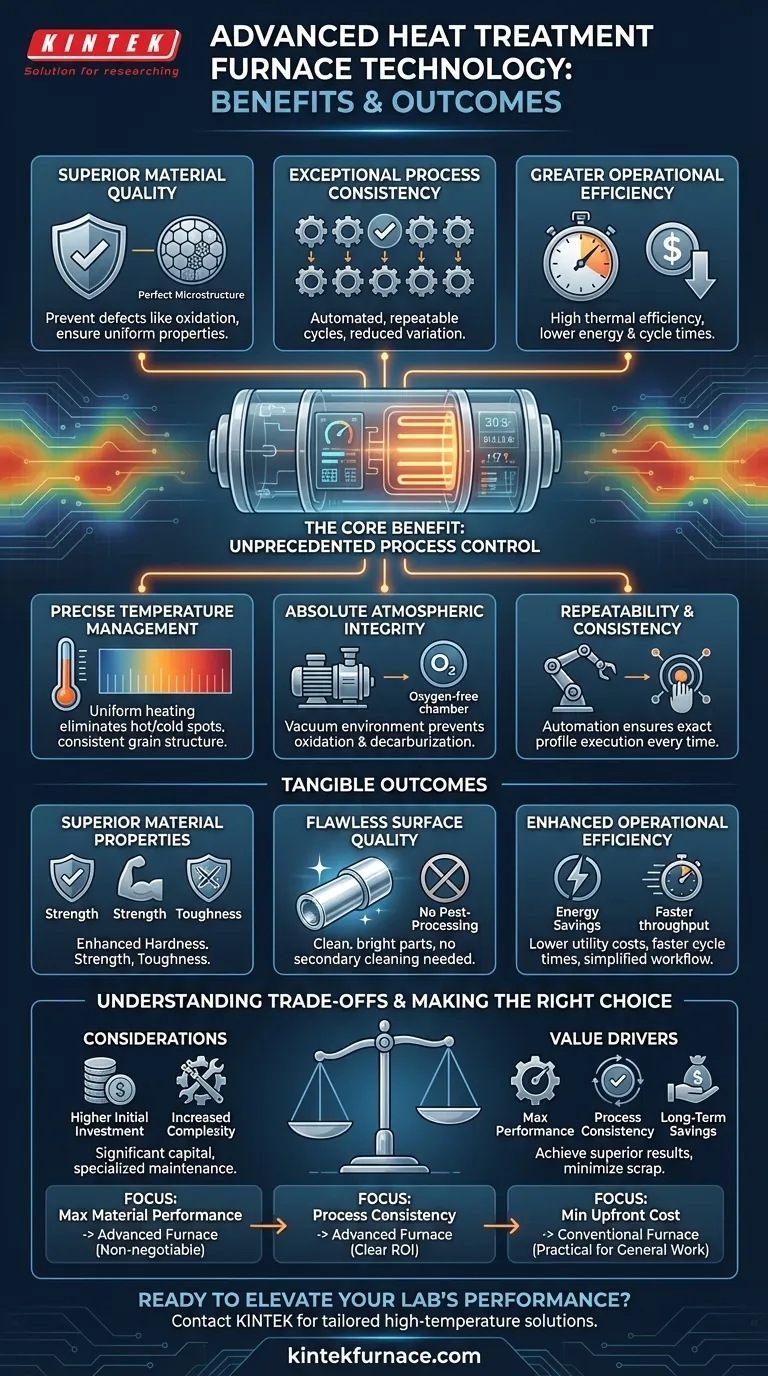

The Core Benefit: Unprecedented Process Control

The primary advantage of modern furnace technology is the ability to tightly manage every variable of the heat treatment cycle. This control is the foundation for all other benefits.

Precise Temperature Management

Advanced furnaces provide exceptionally uniform heating. By eliminating hot and cold spots, they ensure the entire workpiece or batch experiences the exact same thermal profile.

This precision is critical for developing a consistent and homogenous grain structure within the material, which is the basis for predictable mechanical properties.

Absolute Atmospheric Integrity

Many advanced systems are vacuum furnaces. By removing the atmosphere, you eliminate the oxygen, moisture, and other elements that cause negative reactions at high temperatures.

This directly prevents oxidation (scaling) and decarburization (loss of surface carbon and hardness), which are common failures in conventional furnaces. The vacuum environment can also have a cleaning effect, removing oils and other surface contaminants.

Repeatability and Consistency

Through automation and sophisticated sensors, advanced furnaces can execute the exact same heating and cooling profile every single time. This produces invariance—the assurance that the 1,000th part will have the same properties as the first.

This level of repeatability is crucial for industries with strict quality standards, as it drastically reduces part-to-part variation and eliminates the need for costly rework or scrap.

Translating Control into Tangible Outcomes

This new level of process control creates clear and measurable improvements in your products and operations.

Superior Material Properties

Precise thermal cycles and controlled atmospheres allow you to achieve the ideal microstructure. This directly enhances critical mechanical properties like hardness, strength, and toughness.

For specialized components, this control can even improve non-mechanical properties, such as the magnetic characteristics of certain alloys.

Flawless Surface Quality

Because vacuum furnaces prevent oxidation, parts emerge from the cycle clean and bright. This often eliminates the need for secondary post-processing steps like sandblasting, grinding, or chemical cleaning.

The result is a better final product with a lower total processing cost.

Enhanced Operational Efficiency

Modern furnaces are designed for high thermal efficiency, consuming less energy to reach and maintain temperature, which lowers utility costs.

Furthermore, features like rapid cooling systems can shorten cycle times, increasing throughput. The ability to degas and degrease parts within the cycle also simplifies the overall production workflow.

Understanding the Trade-offs

While the benefits are significant, adopting advanced technology requires a clear-eyed assessment of its implications.

Higher Initial Investment

Advanced furnaces, particularly large-scale vacuum systems, represent a significant capital expenditure compared to simpler atmospheric furnaces. The cost is for the precision, the sensors, and the robust construction required to manage a vacuum.

Increased Complexity and Maintenance

These are not simple "set and forget" machines. They involve vacuum pumps, sophisticated control systems, and sensitive instrumentation that require specialized knowledge for operation and a rigorous preventative maintenance schedule.

Not a Universal Solution

For simple annealing or stress-relieving of non-critical, low-carbon steel parts, the precision of a vacuum furnace may be unnecessary. The cost and complexity may not be justified if the application does not demand superior surface finish or tightly controlled mechanical properties.

Making the Right Choice for Your Goal

The decision to invest should be driven by your specific production and quality requirements.

- If your primary focus is maximum material performance and quality: The precise control offered by advanced furnaces is non-negotiable for achieving superior, consistent metallurgical properties.

- If your primary focus is process consistency and reducing rework: The repeatability of an automated, advanced furnace will provide a clear return on investment by minimizing scrap and ensuring product uniformity.

- If your primary focus is minimizing upfront cost for general-purpose work: A conventional atmospheric furnace may remain the more practical and cost-effective choice for less demanding applications.

Ultimately, investing in advanced furnace technology is about gaining precise control over material science to achieve predictable, superior results.

Summary Table:

| Benefit | Key Features |

|---|---|

| Superior Material Quality | Precise temperature control, uniform heating, prevention of oxidation and decarburization |

| Process Consistency | Automation, repeatable cycles, reduced part-to-part variation |

| Operational Efficiency | High thermal efficiency, rapid cooling, reduced energy consumption and cycle times |

| Surface Quality | Clean, bright finishes, elimination of secondary processing |

Ready to elevate your lab's performance with advanced furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior material quality, consistency, and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety