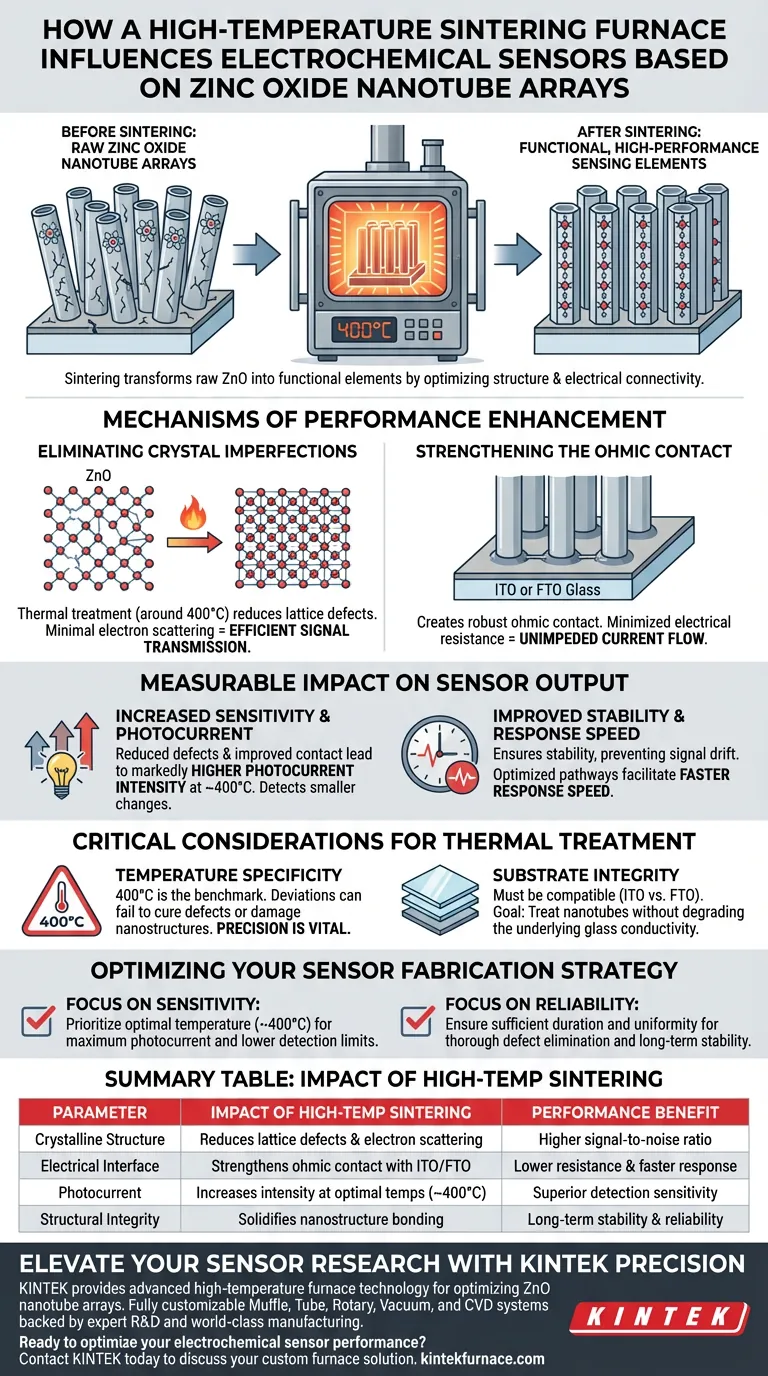

High-temperature sintering is the critical processing step that transforms raw zinc oxide (ZnO) nanotube arrays into functional, high-performance sensing elements. By subjecting the arrays to controlled thermal treatment, typically around 400 degrees Celsius, the furnace optimizes the material's structural integrity and electrical connectivity, resulting in significantly higher sensitivity, stability, and response speed.

The sintering furnace serves as the defining factor in sensor quality, turning a deposited structure into a viable electronic component. It achieves this by simultaneously healing internal crystal defects and solidifying the electrical bond between the nanomaterial and its substrate.

The Mechanisms of Performance Enhancement

To understand how the furnace improves sensor performance, we must look at the changes occurring at the microscopic level.

Eliminating Crystal Imperfections

The primary function of the high-temperature furnace is to remove lattice defects within the zinc oxide structure.

As the nanotubes undergo thermal treatment, the atoms settle into a more ordered crystalline arrangement. This reduction in defects minimizes electron scattering, which is crucial for efficient signal transmission.

Strengthening the Ohmic Contact

For a sensor to work, the sensing material must communicate effectively with the hardware.

Sintering creates a robust ohmic contact between the ZnO nanostructures and the conductive substrate (typically ITO or FTO glass). This ensures that electrical resistance at the interface is minimized, allowing for unimpeded current flow.

Measurable Impact on Sensor Output

The structural improvements delivered by the furnace translate directly into measurable performance metrics for electrochemical biosensors.

Increased Sensitivity and Photocurrent

The reduction of defects and improved contact resistance lead to a marked increase in photocurrent intensity.

For example, sintering at 400 degrees Celsius has been shown to significantly enhance this intensity. A stronger signal directly correlates to higher sensitivity, allowing the sensor to detect smaller changes in the target environment.

Improved Stability and Response Speed

Reliability is just as important as sensitivity in biosensing.

High-temperature treatment ensures the stability of the sensor, preventing signal drift over time. Additionally, the optimized electrical pathways facilitate a faster response speed, making the sensor more reactive to immediate changes.

Critical Considerations for Thermal Treatment

While the benefits are clear, the process relies on precise execution to avoid diminishing returns.

Temperature Specificity

The reference specifically highlights 400 degrees Celsius as a benchmark for enhancing performance.

Deviating significantly from validated temperatures could fail to cure defects or potentially damage the nanostructures. Precision in the furnace’s temperature control is vital.

Substrate Integrity

The process involves heating the entire assembly, including the conductive glass.

The choice of substrate (ITO vs. FTO) must be compatible with the sintering temperatures required to treat the zinc oxide. The goal is to treat the nanotubes without degrading the conductivity of the underlying glass.

Optimizing Your Sensor Fabrication Strategy

To maximize the potential of your zinc oxide nanotube sensors, align your sintering process with your specific performance goals.

- If your primary focus is Sensitivity: Prioritize reaching the optimal sintering temperature (e.g., 400°C) to maximize photocurrent intensity and lower detection limits.

- If your primary focus is Reliability: Ensure the duration and uniformity of the thermal treatment are sufficient to thoroughly eliminate lattice defects for long-term stability.

Precise thermal treatment is the difference between a theoretical concept and a commercially viable electrochemical sensor.

Summary Table:

| Parameter | Impact of High-Temp Sintering | Performance Benefit |

|---|---|---|

| Crystalline Structure | Reduces lattice defects and electron scattering | Higher signal-to-noise ratio |

| Electrical Interface | Strengthens ohmic contact with ITO/FTO substrates | Lower resistance & faster response |

| Photocurrent | Increases intensity at optimal temps (~400°C) | Superior detection sensitivity |

| Structural Integrity | Solidifies nanostructure bonding | Long-term stability & reliability |

Elevate Your Sensor Research with KINTEK Precision

Precision thermal processing is the bridge between a raw nanomaterial and a high-performance biosensor. KINTEK provides the advanced high-temperature furnace technology required to achieve the exact thermal profiles necessary for optimizing ZnO nanotube arrays.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you are aiming to maximize photocurrent intensity or ensure long-term device stability, our systems deliver the uniformity and control your research demands.

Ready to optimize your electrochemical sensor performance?

Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

References

- Ioanna-Aglaia Vagena, Nefeli Lаgopati. Functionalized ZnO-Based Nanocomposites for Diverse Biological Applications: Current Trends and Future Perspectives. DOI: 10.3390/nano14050397

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is the enhancement of coke strength essential? Maximize Blast Furnace Efficiency & Stability

- Why is an industrial electric drying oven required for catalyst support precursors? Secure Pore Integrity

- What role does X-ray diffraction (XRD) play in evaluating ZIF thermal treatment? Master Material Transformation

- What is the temperature of a graphite furnace? Unlock Extreme Heat Up to 3000°C

- How is induced heat generated in a conductive material exposed to a magnetic field? Master Rapid, Contactless Heating

- What is the purpose of using a laboratory blast drying oven at 107°C for 17 hours for reforming catalysts?

- What is the purpose of preheating low carbon steel molds to 300 °C before the casting of Mg-Zn-xSr alloys?

- Why is high-purity argon gas required for MTO synthesis? Ensure Stability in Rhenium Organometallic Catalysis