The primary purpose of preheating low carbon steel molds to 300 °C is to significantly reduce the thermal difference between the molten Mg-Zn-xSr alloy and the mold surface. This critical step moderates the cooling rate, preventing the rapid chilling that leads to structural failures.

Preheating serves as a thermal buffer that safeguards the integrity of the casting. By stabilizing the temperature gradient, you ensure the production of high-density ingots free from shrinkage holes and cracks.

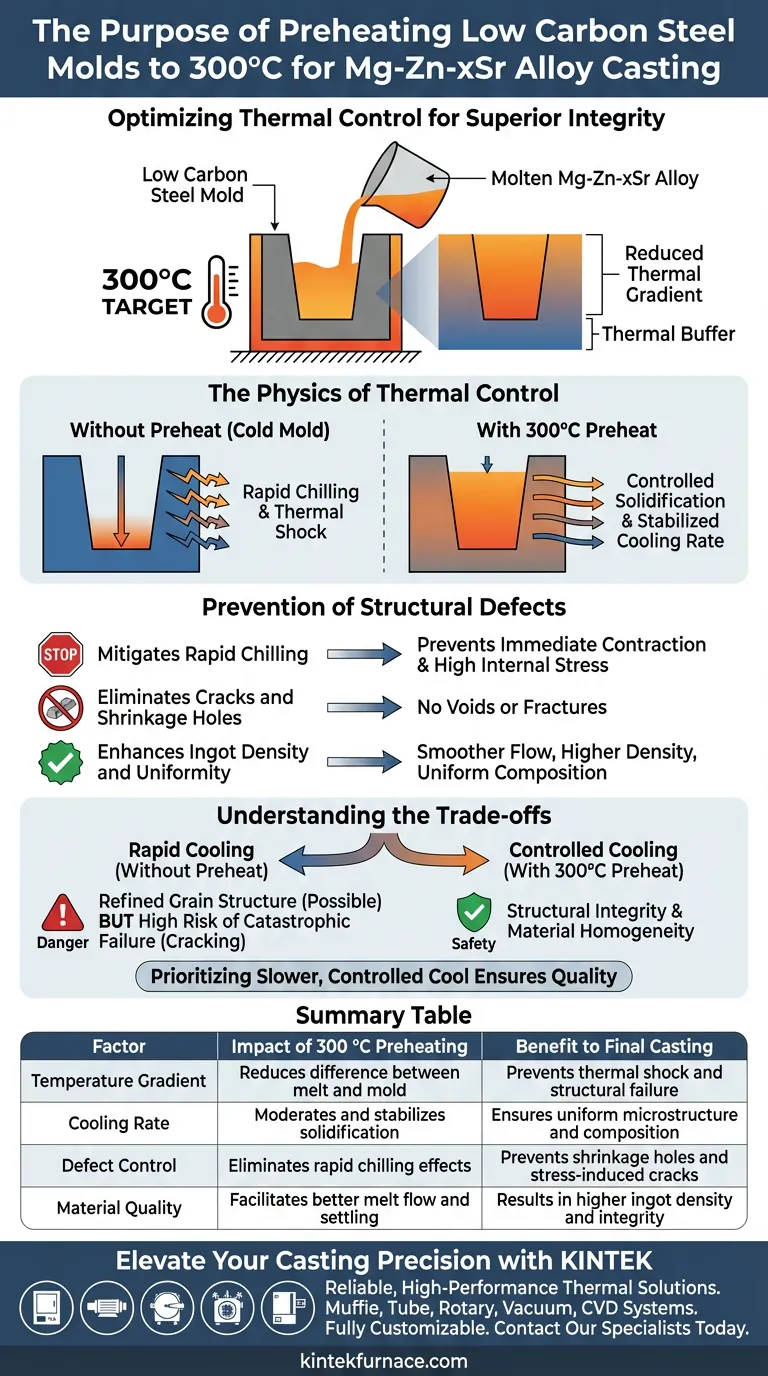

The Physics of Thermal Control

Reducing the Temperature Gradient

When molten metal enters a cold mold, the extreme temperature difference creates a thermal shock.

Preheating the mold to 300 °C bridges this gap. This reduction in the temperature gradient is the fundamental mechanism that allows for a controlled solidification process rather than a chaotic freeze.

Regulating the Cooling Rate

The quality of a magnesium alloy casting is heavily dependent on how fast it cools.

If the mold is too cold, the outer surface of the melt solidifies instantly while the center remains liquid. Preheating ensures the cooling rate is gradual and consistent throughout the ingot, preventing uneven solidification.

Prevention of Structural Defects

Mitigating Rapid Chilling

Rapid chilling occurs when the melt contacts a cold surface, causing immediate contraction.

This phenomenon introduces high internal stresses within the material. By preheating the mold, you eliminate the conditions that cause this rapid, stress-inducing contraction.

Eliminating Cracks and Shrinkage Holes

The most common symptoms of improper thermal management are physical voids and fractures.

Without the 300 °C preheat, the alloy is prone to forming shrinkage holes and cracks. These defects compromise the mechanical strength of the final product and often result in rejected parts.

Enhancing Ingot Density and Uniformity

Beyond preventing cracks, thermal control directly impacts the microstructure.

A preheated mold facilitates a smoother flow and settling of the melt. This results in an ingot with higher density and a more uniform composition, ensuring the Mg-Zn-xSr alloy performs as intended.

Understanding the Trade-offs

The Balance of Cooling Speed

While rapid cooling can sometimes refine grain structure, it is dangerous for these specific alloys in steel molds.

The trade-off here is sacrificing extreme cooling speed for structural integrity. Prioritizing a slower, controlled cool via preheating avoids the catastrophic failure modes (cracking) associated with faster, uncontrolled quenching.

Process Precision

Temperature control must be precise.

Preheating is not merely about "warming up" the mold; it requires reaching the specific target of 300 °C. Deviating significantly below this temperature risks reintroducing the defects the process is designed to avoid.

Optimizing Your Casting Strategy

To ensure high-quality Mg-Zn-xSr alloy castings, apply these principles based on your specific quality targets:

- If your primary focus is Structural Integrity: strict adherence to the 300 °C preheat is non-negotiable to prevent stress fractures and cracking.

- If your primary focus is Material Homogeneity: utilize the preheat to ensure the composition remains uniform across the entire cross-section of the ingot.

Consistency in mold preparation is the single most effective variable for reducing rejection rates in magnesium alloy casting.

Summary Table:

| Factor | Impact of 300 °C Preheating | Benefit to Final Casting |

|---|---|---|

| Temperature Gradient | Reduces difference between melt and mold | Prevents thermal shock and structural failure |

| Cooling Rate | Moderates and stabilizes solidification | Ensures uniform microstructure and composition |

| Defect Control | Eliminates rapid chilling effects | Prevents shrinkage holes and stress-induced cracks |

| Material Quality | Facilitates better melt flow and settling | Results in higher ingot density and integrity |

Elevate Your Casting Precision with KINTEK

Achieving the perfect 300 °C thermal buffer requires reliable, high-performance equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique metallurgical needs.

Don't let thermal stress compromise your Mg-Zn-xSr alloy quality. Contact our specialists today to find the ideal thermal solution for your lab and ensure defect-free, high-density results every time.

Visual Guide

References

- Hongxuan Liu, Jingzhong Xu. Discharge Properties and Electrochemical Behaviors of Mg-Zn-xSr Magnesium Anodes for Mg–Air Batteries. DOI: 10.3390/ma17174179

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a heated substrate platform mitigate the coffee ring effect? Enhance Ag2Se Printing Precision

- What is the role of a precision heating system in HEA synthesis? Achieve Atomic Uniformity at 220 °C

- What role does a high-power graphite resistance furnace play in SiC ceramic treatment? Achieve Perfect Crystallization

- How does the annealing process affect Co3O4/Cu2+1O heterojunction nanowires? Achieve Precise Structural Hybridization

- Why is a furnace with high-precision temperature control required for DPKB-S? Ensuring Material Synthesis Accuracy

- Why is a blank control experiment without a sample required? Ensure Accuracy in Oxide Scale Measurement

- What is the function of wet ball milling in the synthesis of SPAN? Optimize Your Sulfur Content Through Deep Mixing

- What is the function of planetary ball mills or industrial mixing granulators prior to RHF? Optimize FMDS Reactivity