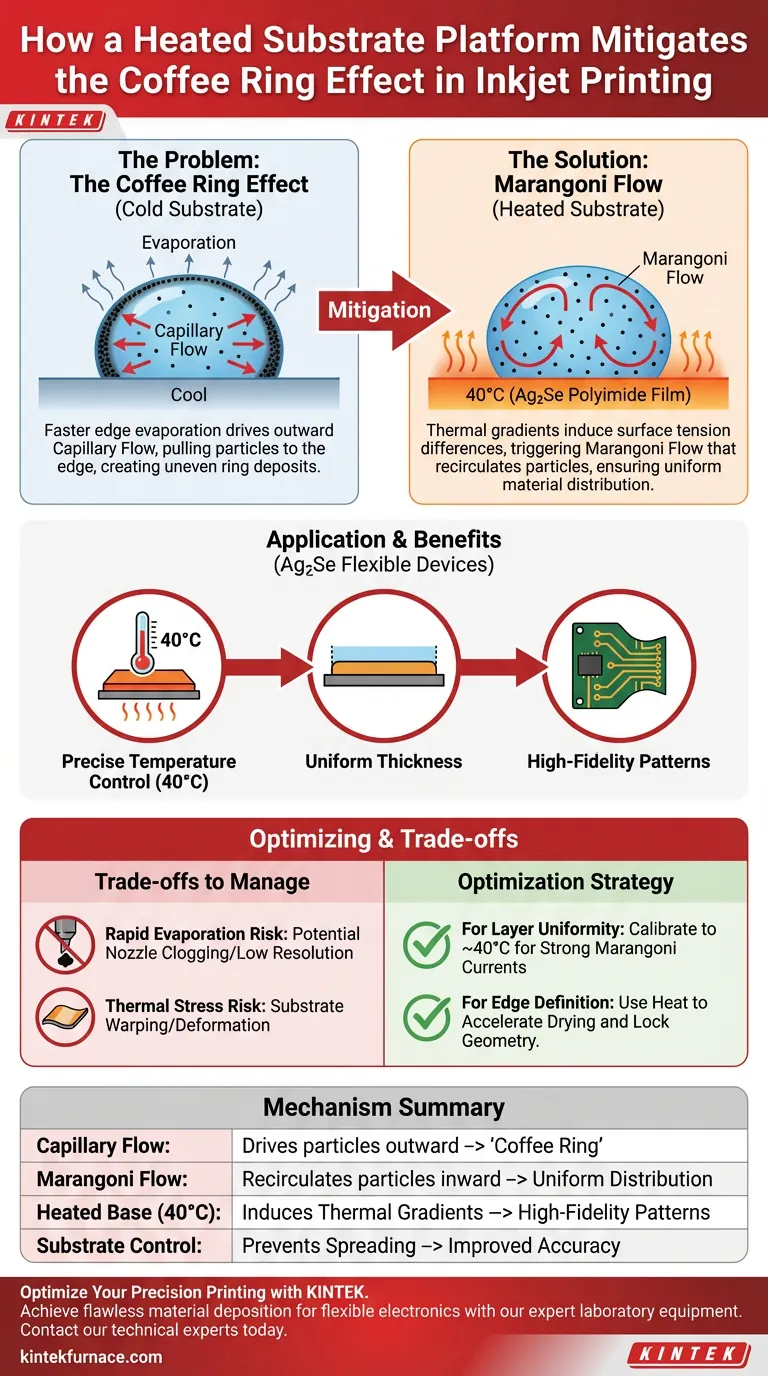

A heated substrate platform actively mitigates the coffee ring effect by altering internal fluid dynamics. By maintaining the printing base—such as a polyimide film—at a controlled temperature like 40°C, the platform accelerates solvent evaporation and creates thermal gradients within the deposited droplet. These gradients induce Marangoni flow, a recirculating force that counteracts the natural outward rush of particles, ensuring a uniform distribution of Ag2Se material rather than a concentrated ring at the edges.

The coffee ring effect naturally pulls suspended particles to the edge of a drying droplet due to uneven evaporation rates. Heating the substrate disrupts this process by driving a thermally induced Marangoni flow that recirculates particles back toward the center, resulting in uniform thickness and high-fidelity patterns.

The Mechanism of Defect Suppression

The Natural Tendency: Capillary Flow

When a droplet containing particles (like Ag2Se ink) lands on a surface, evaporation occurs faster at the pinned edges than at the center.

To replenish the liquid lost at the edges, fluid flows outward from the center of the drop. This outward capillary flow carries the suspended particles with it, depositing them in a ring-like formation as the solvent dries.

The Counter-Measure: Marangoni Flow

A heated substrate introduces a temperature differential between the hot base and the cooler top of the droplet.

This temperature difference creates a gradient in surface tension. Because fluids naturally flow from areas of low surface tension to high surface tension, a recirculating flow—known as the Marangoni flow—is triggered.

This inward flow effectively opposes the outward capillary flow. It acts as a mixer, preventing particles from accumulating at the contact line and redistributing them evenly across the footprint of the droplet.

Application in Ag2Se Flexible Devices

Precise Temperature Control

For materials like silver selenide (Ag2Se), maintaining the substrate at a specific temperature is critical. The primary reference highlights 40°C as an effective set point for polyimide film substrates.

This temperature is high enough to accelerate evaporation and induce the necessary thermal gradients, but low enough to remain safe for the flexible polymer base.

Ensuring Structural Fidelity

The ultimate goal of this thermal management is ensuring the geometric accuracy of the printed device.

By suppressing edge deposition, the heated platform guarantees that the printed patterns achieve uniform thickness. This is vital for electronic devices, where variations in thickness can lead to inconsistent conductivity or device failure.

Furthermore, this process results in high-fidelity edge profiles, ensuring that the actual printed features match the intended design without spreading or irregular boundaries.

Understanding the Trade-offs

The Risk of Rapid Evaporation

While heating is beneficial, there is a balance to be struck. If the substrate temperature is too high, the solvent may evaporate too quickly.

This can lead to nozzle clogging if the heat radiates back to the printhead, or it may cause the droplet to dry before it spreads sufficiently, affecting the resolution.

Thermal Stress on Substrates

The reference specifies polyimide, which is thermally stable. However, when applying this technique to other flexible substrates, one must consider the material's glass transition temperature.

Excessive heat could cause the substrate to warp or deform, potentially ruining the alignment of the printed circuit.

Optimizing Your Printing Strategy

To achieve the best results when inkjet printing Ag2Se devices, you must treat temperature as a primary printing parameter, not just an environmental variable.

- If your primary focus is layer uniformity: Calibrate your substrate temperature to roughly 40°C to generate strong Marangoni currents that maximize particle redistribution.

- If your primary focus is edge definition: Use the heated platform to accelerate drying times, locking the droplet's geometry in place before it can spread uncontrollably.

By mastering the thermal gradients within your ink droplets, you transform the chaotic physics of drying into a precision tool for device fabrication.

Summary Table:

| Mechanism | Impact on Fluid Dynamics | Resulting Effect on Printing |

|---|---|---|

| Capillary Flow | Drives fluid and particles toward the pinned edges | Creates uneven "coffee ring" deposits |

| Marangoni Flow | Recirculates particles via thermal surface tension gradients | Ensures uniform material distribution |

| Heated Base (40°C) | Accelerates evaporation and induces thermal gradients | High-fidelity patterns & consistent thickness |

| Substrate Control | Prevents uncontrolled droplet spreading | Improved geometric accuracy and resolution |

Optimize Your Precision Printing with KINTEK

Achieve flawless material deposition and uniform thickness for your flexible electronics. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of laboratory equipment including high-precision heating systems and customizable high-temp furnaces—such as Muffle, Tube, Rotary, Vacuum, and CVD systems—designed to meet the unique thermal management needs of your research.

Ready to eliminate printing defects and enhance your device performance?

Contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Yan Liu, Wan Jiang. Fully inkjet-printed Ag2Se flexible thermoelectric devices for sustainable power generation. DOI: 10.1038/s41467-024-46183-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- What design considerations are important for custom vacuum chambers? Optimize for Performance, Cost, and Application Needs

- What is the purpose of using a vacuum drying oven in the post-treatment of Pd/BPC catalysts? Optimize Performance.

- How does high-temperature filtration equipment facilitate molten salt separation? Boost Your Slag Treatment Recovery

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What are the energy consumption advantages of an industrial microwave pre-treatment system? Save Over 50% Energy

- What are some common applications of laboratory furnaces? Unlock Precision in Material Transformation

- What is the significance of using a laboratory vacuum drying oven during the catalyst recovery phase of depolymerization?

- Why is the continuous injection of high-purity argon required? Achieve Unmatched Purity in Cast Iron Melting