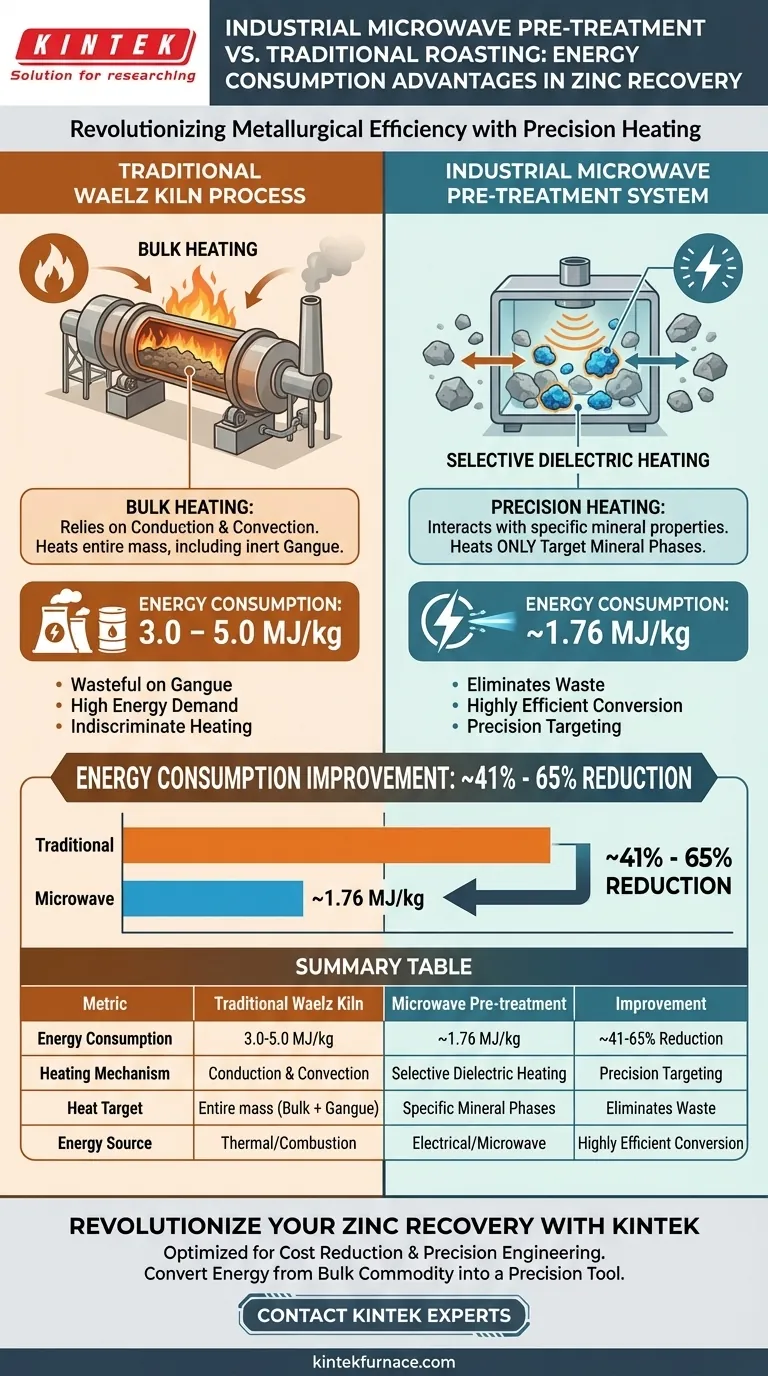

Industrial microwave pre-treatment significantly reduces energy consumption by changing how heat is applied to the material. While traditional Waelz kiln processes typically require between 3 and 5 MJ/kg to process zinc clinker, an industrial microwave system accomplishes the same task with approximately 1.76 MJ/kg.

By utilizing selective heating, microwave systems direct energy only to the target minerals rather than the bulk material, effectively eliminating the energy wasted on heating inert gangue.

The Mechanics of Efficiency

Selective Mineral Heating

Traditional roasting is a thermal process that relies on conduction and convection. To reach the reaction temperature, you must heat the entire mass of material, including the air inside the kiln.

Microwave systems operate differently by interacting directly with the dielectric properties of specific minerals. This allows the system to heat the target mineral phases specifically, rather than bringing the entire environment up to temperature.

Eliminating Waste on Gangue

In any ore or clinker, a significant portion of the mass is "gangue"—valueless rock or material surrounding the desired metal.

In a traditional Waelz kiln, energy is consumed indiscriminately to heat this gangue. Microwave pre-treatment avoids this ineffective energy loss, ensuring that energy input correlates directly with the recovery of the metal, not the volume of the waste rock.

Comparative Energy Metrics

The Microwave Benchmark

For the processing of zinc clinker, the unit energy consumption of microwave pre-treatment is drastically lower than thermal alternatives.

Data indicates these systems operate at approximately 1.76 MJ/kg. This represents a highly efficient conversion of electrical energy into metallurgical progress.

The Traditional Benchmark

Conventional methods, specifically the Waelz kiln process, are far more energy-intensive due to the need for bulk heating.

These processes typically consume between 3 and 5 MJ/kg. This results in an energy demand that is roughly 1.7 to 2.8 times higher than that of the microwave alternative.

Understanding the Operational Requirements

Dependency on Mineral Properties

The efficiency of this system relies entirely on the principle of selectivity.

For the energy savings to be realized, the target mineral phase must be responsive to microwave frequencies. If the zinc-bearing material does not absorb microwave energy significantly better than the gangue, the efficiency gap narrows.

Material Composition Constraints

This process is optimized for materials where the target phase is distinct from the gangue.

If the ore mineralogy is such that the target phase is not sufficiently liberated or distinct, the microwave system may lose its ability to heat selectively. The advantage exists only when the "target" can be isolated thermally from the "bulk."

Making the Right Choice for Your Goal

- If your primary focus is Operating Cost Reduction: The microwave system offers a superior energy profile, cutting consumption by nearly half compared to standard kilns.

- If your primary focus is Processing Non-Responsive Ores: You must verify the dielectric properties of your specific zinc clinker to ensure it allows for selective heating.

Switching to microwave pre-treatment converts energy from a bulk commodity into a precision tool, strictly targeting the value in your material.

Summary Table:

| Metric | Traditional Waelz Kiln | Microwave Pre-treatment | Improvement |

|---|---|---|---|

| Energy Consumption | 3.0 - 5.0 MJ/kg | ~1.76 MJ/kg | ~41% - 65% Reduction |

| Heating Mechanism | Conduction & Convection | Selective Dielectric Heating | Precision Targeting |

| Heat Target | Entire mass (Bulk + Gangue) | Specific Mineral Phases | Eliminates Waste |

| Energy Source | Thermal/Combustion | Electrical/Microwave | Highly Efficient Conversion |

Revolutionize Your Zinc Recovery with KINTEK

Are high energy costs limiting your production efficiency? KINTEK provides industry-leading thermal solutions designed to optimize your metallurgical processes. Backed by expert R&D and manufacturing, we offer a wide range of customizable high-temperature systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, tailored to your unique material requirements.

By partnering with KINTEK, industrial mining and processing customers benefit from:

- Precision Engineering: Systems designed to exploit selective mineral heating.

- Cost Reduction: Cutting energy consumption by nearly half compared to traditional kilns.

- Scalable Innovation: Lab-to-production scale equipment built for durability.

Ready to convert energy from a bulk commodity into a precision tool? Contact our experts today to discover how KINTEK’s advanced systems can enhance your lab or industrial facility's performance.

Visual Guide

References

- Bagdaulet Kenzhaliyev, Symbat Tugambay. Microwave Pre-Treatment for Efficient Zinc Recovery via Acid Leaching. DOI: 10.3390/ma18112496

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does a releasing agent play during the assembly process of titanium-steel composite plates?

- How does the post-rolling annealing process improve the interfacial microstructure? Enhancing Titanium-Steel Bond Strength

- What experimental conditions does a high-temperature continuous flow fixed-bed reactor provide for Zn-Cr catalysts?

- How do quartz-capped vials facilitate the pyrolysis of magnetic chitosan carbon? Master Localized Reducing Atmospheres

- Why is a laboratory electric blast drying oven necessary for determining the water absorption rate of mortar?

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?

- Why is a sealed heating vessel used with a stepped heating process to infiltrate sulfur? Maximize Li-S Battery Performance

- What are the advantages of the sol-gel nitrate combustion method? Achieve Atomic-Level Purity in Oxide Synthesis