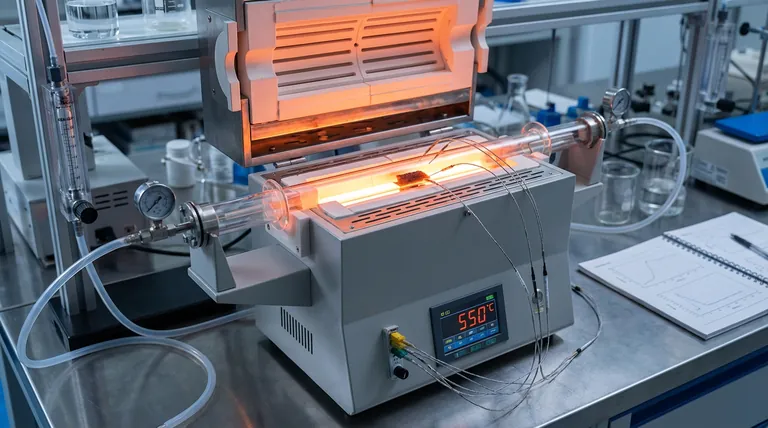

A high-temperature continuous flow fixed-bed reactor creates a precise, simulated industrial environment. It operates between 500°C and 550°C for up to 150 hours with a Weight Hourly Space Velocity (WHSV) of 7500 mL/g·h. This specific configuration, utilizing quartz reaction tubes and K-type thermocouple controls, allows researchers to measure how Zn-Cr catalysts withstand long-term thermochemical stress.

This testing environment bridges the gap between lab-scale experimentation and industrial reality. By maintaining rigorous thermochemical conditions over an extended period, it isolates the effects of heat and flow on catalyst structure and carbon deposition.

Simulation of Industrial Stress

Temperature Ranges and Control

The system maintains temperatures between 500°C and 550°C, which are critical for testing thermal degradation in Zn-Cr systems. K-type thermocouples ensure high-precision temperature regulation, preventing thermal runaway or fluctuations that could skew stability data.

The Importance of Temporal Stability

The reactor supports continuous flow for up to 150 hours. This duration is essential for identifying slow-onset structural changes or the gradual accumulation of carbon that shorter tests might miss.

Kinetic and Material Parameters

Standardized Weight Hourly Space Velocity (WHSV)

A constant WHSV of 7500 mL/g·h is maintained throughout the evaluation process. This consistency ensures that any observed deactivation is a result of catalyst instability rather than variations in contact time or reactant flow.

Quartz Tube Integrity

The use of quartz reaction tubes minimizes unwanted catalytic wall effects. This ensures that the observed chemical reactions and carbon resistance data are purely a reflection of the atomic synergistic active sites within the catalyst.

Understanding Potential Trade-offs

Limitations of the 150-Hour Window

While 150 hours is a rigorous benchmark, it may not capture deactivation mechanisms that only emerge after thousands of hours of industrial use. Researchers must extrapolate these results carefully when predicting the multi-year lifespan of a catalyst.

Fixed-Bed Constraints

The fixed-bed design provides excellent stability data but may not fully simulate the mechanical stresses found in fluidized bed environments. Catalyst attrition or physical fragmentation might be underestimated in this static configuration compared to more dynamic reactor types.

Implementing These Conditions for Catalyst Development

To maximize the utility of this reactor setup, align your experimental goals with the specific capabilities of the system.

- If your primary focus is structural integrity: Prioritize the full 150-hour duration at the upper temperature limit of 550°C to stress the atomic synergistic sites.

- If your primary focus is carbon resistance: Maintain the 7500 mL/g·h WHSV strictly to observe how flow dynamics influence coke formation on the catalyst surface.

By replicating industrial-grade thermochemical stress, this reactor setup provides the definitive data required to validate catalyst durability for large-scale applications.

Summary Table:

| Feature | Experimental Condition Specification |

|---|---|

| Temperature Range | 500°C to 550°C |

| Test Duration | Up to 150 hours (continuous) |

| Flow Rate (WHSV) | 7500 mL/g·h |

| Temperature Control | K-type thermocouples for high precision |

| Reaction Vessel | High-integrity quartz tubes |

| Primary Goal | Evaluate thermal stability & carbon resistance |

Elevate Your Catalyst Research with KINTEK

Precision in thermal stability testing requires equipment that can withstand rigorous industrial simulation. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to deliver the exact thermochemical environments your research demands.

Backed by expert R&D and world-class manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique experimental parameters. Ensure your catalysts are ready for industrial scale-up with our reliable heating solutions.

Ready to optimize your lab's performance? Contact us today to discuss your custom furnace needs!

References

- Ji Yang, Ji Su. Atomically synergistic Zn-Cr catalyst for iso-stoichiometric co-conversion of ethane and CO2 to ethylene and CO. DOI: 10.1038/s41467-024-44918-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does Vacuum Degassing (VD) influence spinel inclusions in heavy rail steel? Controlling Refractory Erosion

- How does a continuous furnace differ from a batch furnace? Optimize Your Heat Treatment Process

- How does the introduction of SiO2 as an additive improve the sintering process of solid electrolytes? Boost Densification

- What is sintering in the context of 3D printing? Unlock Dense, Functional Parts with Precision

- What is the function of a Laboratory Forced Air Drying Oven in fruit waste pretreatment? Ensure Superior Carbon Yields

- What are the advantages of using microwave plasma for aluminum powder reduction? Achieve Unmatched Material Purity

- How does high-temperature calcination affect kaolin? Boost Surface Area and Catalytic Reactivity via Thermal Processing

- How does a laboratory oven contribute to the hydrothermal treatment of graphene aerogels? Master High-Strength Synthesis