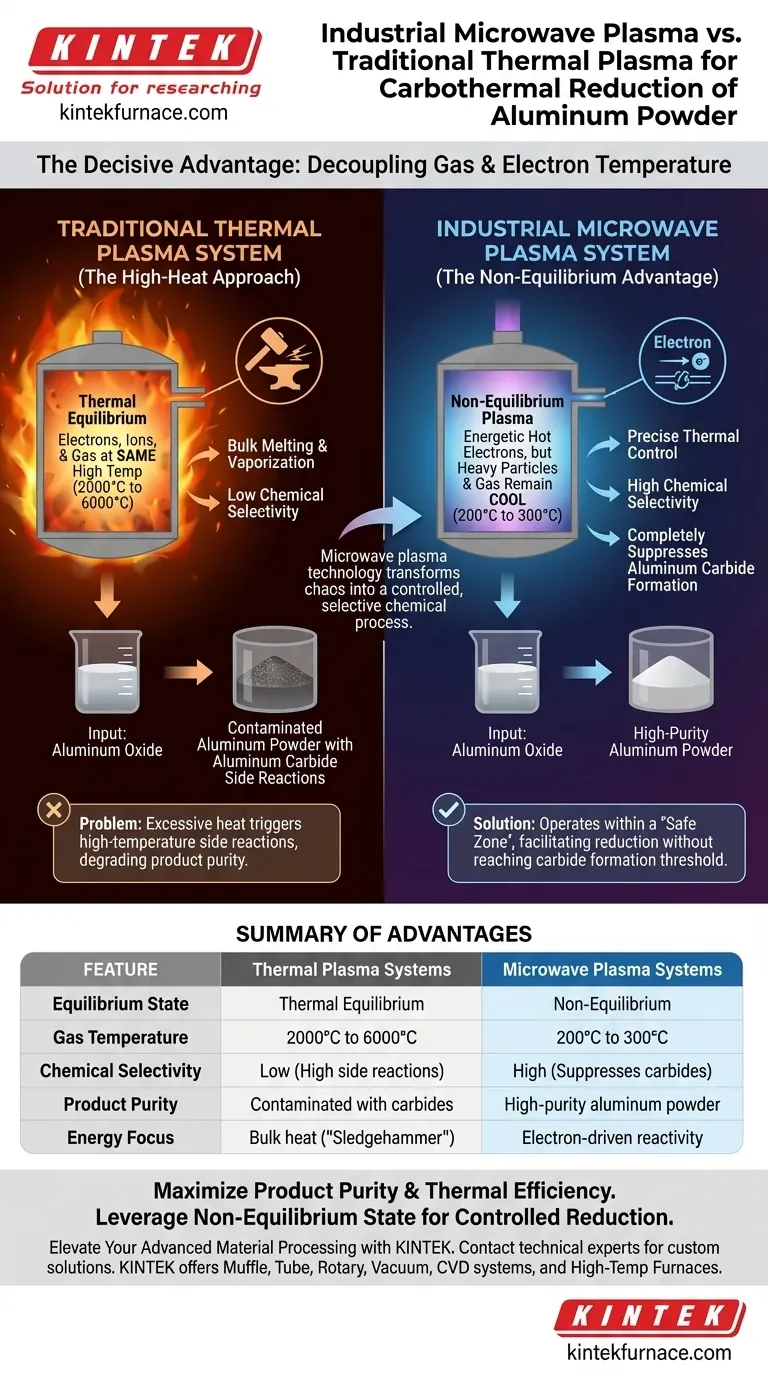

The decisive advantage of industrial microwave plasma systems is their ability to decouple gas temperature from electron temperature. While traditional thermal systems rely on brute-force heat, microwave plasma systems utilize non-equilibrium plasma to keep gas temperatures between 200 and 300 °C. This precise thermal control facilitates the reduction of aluminum oxide while completely suppressing the thermodynamic conditions required for aluminum carbide formation, ensuring a high-purity final product.

By maintaining a non-equilibrium state, microwave plasma systems solve the primary chemical challenge of aluminum processing: reducing oxides without triggering the high-temperature side reactions that contaminate the material with carbides.

The Physics of Temperature Control

To understand why microwave plasma is superior for this specific application, one must look at how energy is transferred within the system.

Thermal Plasma: The High-Heat Approach

Traditional thermal plasma systems operate on the principle of thermal equilibrium. In these environments, the electrons, ions, and neutral gas species all exist at roughly the same temperature.

Consequently, these systems generate extreme heat, typically ranging from 2000 to 6000 °C. While effective for bulk melting, this "sledgehammer" approach lacks selectivity.

Microwave Plasma: The Non-Equilibrium Advantage

Industrial microwave plasma systems generate non-thermal, non-equilibrium plasma. In this state, the electrons are highly energetic and hot, but the heavy particles (ions and neutral gas molecules) remain relatively cool.

This mechanism allows the system to maintain overall gas temperatures in the 200 to 300 °C range. You achieve the necessary reactivity through electron impact without subjecting the bulk material to destructive thermal loads.

Achieving Chemical Selectivity

The primary engineering challenge in the carbothermal reduction of aluminum is preventing impurities. The temperature difference between the two systems dictates the chemical outcome.

The Aluminum Carbide Problem

In high-temperature environments (such as those found in thermal plasma), the chemical reaction does not stop at the reduction of aluminum oxide.

The excessive heat provides the activation energy for aluminum carbide side reactions. Once formed, these carbides act as contaminants, degrading the quality and applicability of the aluminum powder.

Preserving Product Purity

Microwave plasma systems operate strictly within a "safe zone." The gas temperature of 200–300 °C is sufficient to facilitate the reduction of aluminum oxide when driven by energetic electrons.

Crucially, this temperature is far too low to support the formation of aluminum carbide. By physically preventing the system from reaching the thermal threshold for carbide creation, high purity is engineered directly into the process.

Understanding the Operational Constraints

While microwave plasma offers superior purity, it introduces specific operational constraints that differ from thermal systems.

The Process Window

The system relies on maintaining a non-equilibrium state. This requires precise control to ensure the gas temperature remains between the 200 and 300 °C targets.

Feedstock Limitations

Because the bulk gas temperature is low, this method is strictly a reduction technique. It is not suitable for applications requiring the bulk melting or vaporization of materials that have melting points significantly higher than 300 °C, unless the reaction kinetics are driven entirely by non-thermal electron interactions.

Making the Right Choice for Your Project

The choice between thermal and microwave plasma depends entirely on your tolerance for impurities and your specific processing goals.

- If your primary focus is maximizing product purity: utilize microwave plasma to ensure the reduction of oxides occurs without the risk of aluminum carbide contamination.

- If your primary focus is thermal efficiency: leverage the non-equilibrium nature of the system to perform chemical reduction at 200–300 °C, avoiding the massive energy input required to heat gas to 6000 °C.

Microwave plasma technology effectively transforms the carbothermal reduction of aluminum from a chaotic thermal event into a controlled, selective chemical process.

Summary Table:

| Feature | Thermal Plasma Systems | Microwave Plasma Systems |

|---|---|---|

| Equilibrium State | Thermal Equilibrium | Non-Equilibrium |

| Gas Temperature | 2000°C to 6000°C | 200°C to 300°C |

| Chemical Selectivity | Low (High side reactions) | High (Suppresses carbides) |

| Product Purity | Contaminated with carbides | High-purity aluminum powder |

| Energy Focus | Bulk heat ("Sledgehammer") | Electron-driven reactivity |

Elevate Your Advanced Material Processing with KINTEK

Don't let high-temperature side reactions compromise your product quality. KINTEK provides industry-leading thermal solutions designed for precision and purity. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to meet your unique carbothermal and plasma processing needs.

Ready to optimize your lab's efficiency? Contact our technical experts today to find your custom solution!

Visual Guide

References

- Alexander Logunov, Sergey S. Suvorov. Plasma–Chemical Low-Temperature Reduction of Aluminum with Methane Activated in Microwave Plasma Discharge. DOI: 10.3390/met15050514

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Spark Plasma Sintering SPS Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the key advantages of using an annealing furnace? Enhance Material Quality and Manufacturing Efficiency

- What is the purpose of conducting high-temperature tensile testing on TC4 titanium alloy? Master Thermal Forming Limits

- What is the primary role of the Thermal Oxidation (TO) process in Ti-6Al-4V ELI alloy? Enhancing Hardness and Wear

- How does temperature control affect nanoporous copper dealloying? Master Pore Uniformity and Size

- How can I improve my vacuum pump performance? Optimize Your System for Deeper Vacuum & Faster Pump-Down

- What is the function of a vacuum drying oven in CMS synthesis? Ensure High-Purity Precursor Integrity

- What is the chemical vapor transport technique? A Guide to High-Purity Crystal Growth

- What are the specific equipment operational requirements for the SRS process? Unlock Precise Strain Engineering