The primary function of a vacuum drying oven in this context is to thoroughly remove solvents and moisture from monomers and polymers without subjecting them to damaging thermal stress. Specifically, this process is applied during the synthesis of monomers (such as BP, BM, and TF) and the final polyimide polymers used as precursors for Carbon Molecular Sieves (CMS).

Core Insight: The value of vacuum drying lies not just in removing moisture, but in doing so at low temperatures. By lowering the boiling point of solvents, the oven prevents oxidation and thermal degradation, preserving the delicate chemical structure required for successful pyrolysis.

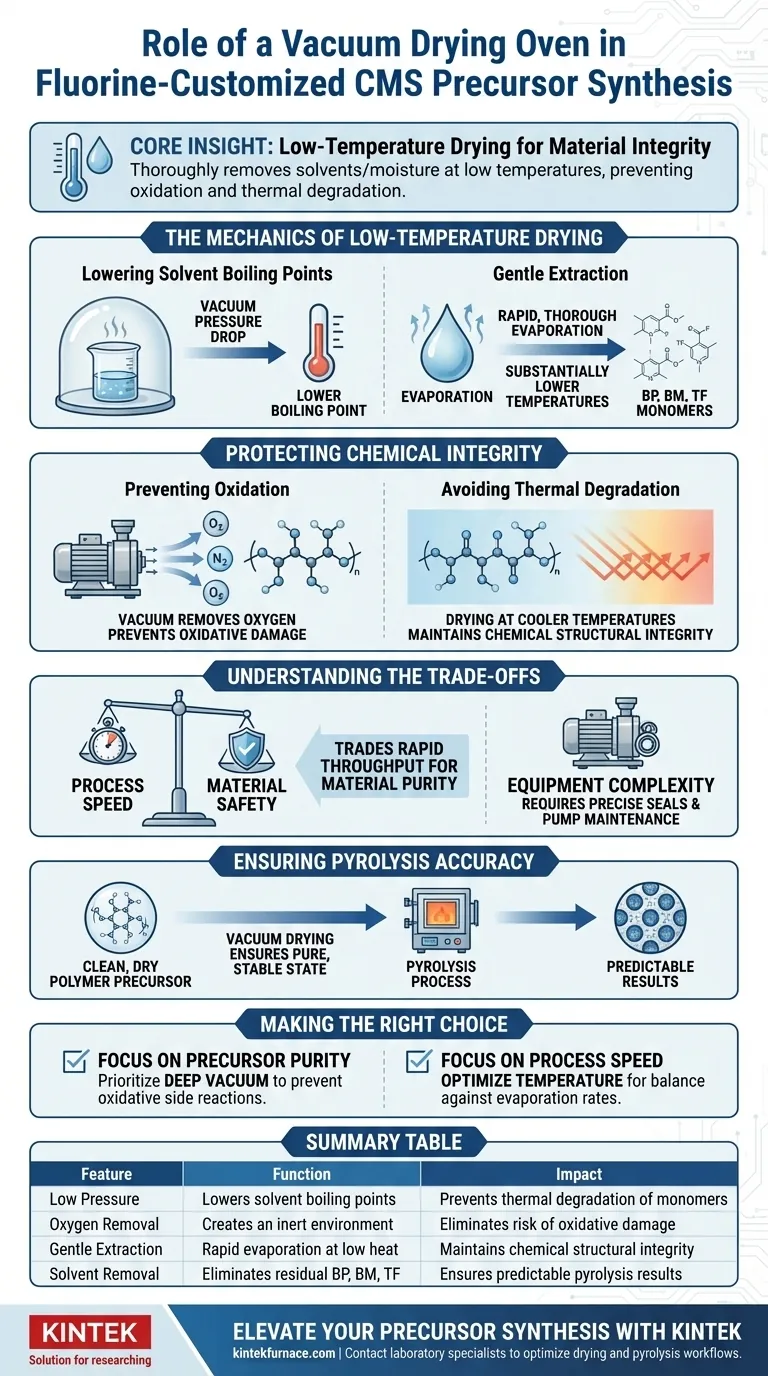

The Mechanics of Low-Temperature Drying

Lowering Solvent Boiling Points

In a standard oven, removing stubborn solvents often requires high heat. A vacuum drying oven creates a low-pressure environment that significantly lowers the boiling point of residual solvents and moisture.

Gentle Extraction

This pressure differential allows for rapid, thorough evaporation at substantially lower temperatures. This is critical for processing delicate monomers like BP, BM, and TF, ensuring they reach a dry state without requiring excessive thermal energy.

Protecting Chemical Integrity

Preventing Oxidation

Standard drying processes expose materials to heated air, which increases the risk of oxidation. The vacuum environment removes oxygen from the chamber, effectively preventing oxidative damage to the polymer precursor.

Avoiding Thermal Degradation

High temperatures can cause polymer chains to break down or cross-link prematurely. By facilitating drying at cooler temperatures, the vacuum oven maintains the chemical structural integrity of the polyimide polymers.

Understanding the Trade-offs

Process Speed vs. Material Safety

While vacuum drying is gentler, it can be slower than high-temperature blast drying if the vacuum pressure is not optimized. You trade rapid throughput for material purity and structural assurance.

Equipment Complexity

Maintaining a consistent vacuum requires precise seals and pump maintenance. Any leakage introduces oxygen and moisture, effectively negating the benefits of the process and potentially contaminating the CMS precursor.

Ensuring Pyrolysis Accuracy

The Foundation for Carbonization

The quality of the final Carbon Molecular Sieve is dictated by the quality of the precursor. If the precursor contains residual solvent or has suffered thermal damage, the subsequent pyrolysis process will yield unpredictable results.

Stabilizing the Precursor

Vacuum drying ensures the material enters the pyrolysis stage in a pure, chemically accurate state. This stability is required to achieve the precise pore sizing and separation capabilities expected from fluorine-customized CMS.

Making the Right Choice for Your Goal

To maximize the efficacy of your synthesis process, consider your specific priorities:

- If your primary focus is precursor purity: Prioritize a deep vacuum level to ensure complete solvent removal at the lowest possible temperature to prevent any oxidative side reactions.

- If your primary focus is process speed: Optimize the temperature to the highest safe limit for your specific polyimide variant, balancing thermal stability against evaporation rates.

By controlling the drying environment, you secure the structural fidelity of the precursor before it ever reaches the pyrolysis furnace.

Summary Table:

| Feature | Function in CMS Synthesis | Impact on Precursor Quality |

|---|---|---|

| Low Pressure | Lowers solvent boiling points | Prevents thermal degradation of monomers |

| Oxygen Removal | Creates an inert environment | Eliminates risk of oxidative damage |

| Gentle Extraction | Rapid evaporation at low heat | Maintains chemical structural integrity |

| Solvent Removal | Eliminates residual BP, BM, TF | Ensures predictable pyrolysis results |

Elevate Your Precursor Synthesis with KINTEK

Precision in vacuum drying is the foundation for high-performance Carbon Molecular Sieves. At KINTEK, we understand that maintaining chemical integrity during monomer and polymer processing is non-negotiable.

Backed by expert R&D and industry-leading manufacturing, KINTEK offers advanced Vacuum, Muffle, Tube, and CVD systems designed to provide the stable, oxygen-free environments your research demands. Whether you need customized high-temperature furnaces or precise vacuum control for delicate polyimides, our solutions are tailored to your unique lab requirements.

Ready to optimize your drying and pyrolysis workflows? Contact our laboratory specialists today to discover how KINTEK can enhance your material purity and process reliability.

Visual Guide

References

- Shan Xu, Yunlong Ji. High‐Performance Carbon Capture with Fluorine‐Tailored Carbon Molecular Sieve Membranes. DOI: 10.1002/adma.202420477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is vacuum impregnation necessary for PAN-GF electrodes? Ensure Peak Fiber Conductivity and Slurry Integration

- What is the purpose of using a continuous annealing furnace? Optimize Silicon Steel Normalization & Performance

- What are the advantages of using a customized multimode microwave reaction furnace? Boost Synthesis Speed by 90%

- Why is a high-pressure stainless steel autoclave required for activated carbon? Unlock High-Performance Carbon Synthesis

- Why is a furnace with high-precision temperature control required for DPKB-S? Ensuring Material Synthesis Accuracy

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- What is the significance of FE-SEM for SSBSN ceramics? Master Morphological Analysis for Superior Electrical Performance

- What is the specific purpose of using a laboratory oven for the treatment of copper oxide precipitates? Expert Insights