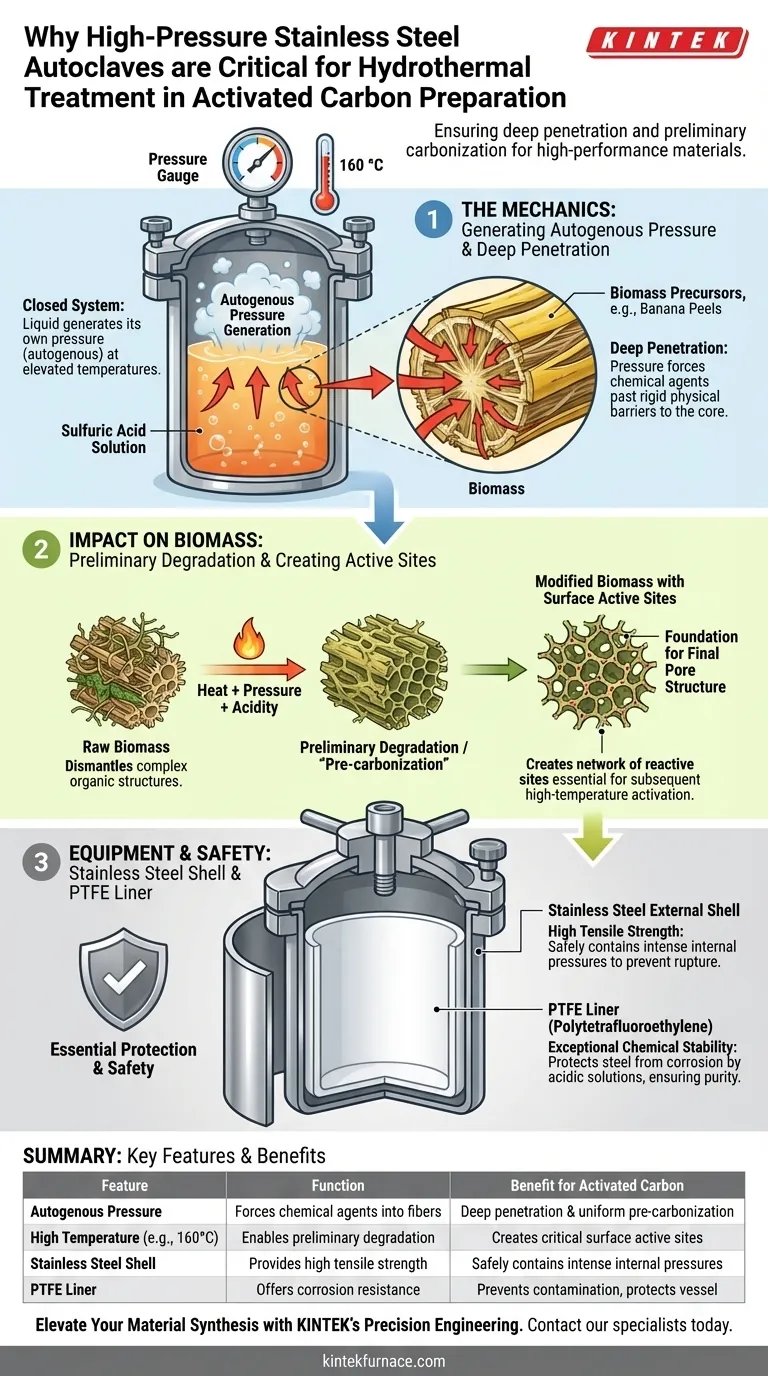

A high-pressure stainless steel autoclave is required because it creates a sealed environment capable of generating autogenous pressure at elevated temperatures, typically around 160 °C. This pressurized atmosphere forces chemical agents, such as sulfuric acid solutions, to penetrate deeply into the stubborn structural fibers of biomass precursors like banana peels.

Core Insight The autoclave does not merely heat the material; it acts as a catalyst for preliminary carbonization. By breaking down biomass structures under high pressure, it generates critical surface active sites that are necessary for the subsequent high-temperature activation stage to be effective.

The Mechanics of Hydrothermal Treatment

Generating Autogenous Pressure

The autoclave functions as a closed system. When the solution inside is heated to temperatures like 160 °C, it cannot evaporate into the atmosphere. Instead, the liquid generates its own pressure (autogenous pressure), creating an environment significantly more reactive than standard open-air heating.

Facilitating Deep Penetration

Biomass precursors often possess rigid, fibrous structures that resist chemical attack. The high pressure generated within the autoclave forces the sulfuric acid solution past these physical barriers. This ensures the chemical agent reaches the core of the material rather than just reacting with the outer surface.

Impact on Biomass Structure

Preliminary Degradation

Inside this high-pressure thermal environment, the biomass undergoes preliminary degradation. The combination of heat, pressure, and acidity begins to dismantle the complex organic structures of the raw material. This process is effectively a "pre-carbonization" stage, preparing the material for the more intense thermal processing that follows.

Creating Surface Active Sites

The ultimate goal of this stage is to modify the material's surface chemistry. By breaking down the stubborn fibers, the hydrothermal treatment creates a network of surface active sites. These sites are the foundation upon which the final pore structure of the activated carbon will be built during the final activation phase.

Operational Considerations and Safety

The Role of Stainless Steel

The "stainless steel" specification refers to the vessel's external shell. This material is selected for its high tensile strength, which is required to safely contain the immense internal pressures generated during the reaction. A weaker material would pose a significant risk of rupture or explosion.

Essential Protection Against Corrosion

While the stainless steel provides structural integrity, it is vulnerable to corrosion from the strong acidic or alkaline solutions used in hydrothermal synthesis. Therefore, a Polytetrafluoroethylene (PTFE) liner is often utilized inside the steel shell. This liner offers exceptional chemical stability, preventing the reaction solution from corroding the autoclave body and ensuring the purity of the carbon precursor.

Making the Right Choice for Your Goal

To ensure successful activated carbon preparation, align your equipment choice with your specific processing needs:

- If your primary focus is maximizing adsorption capacity: Ensure your autoclave can sustain the specific temperatures (e.g., 160 °C) required to generate sufficient pressure for deep pore development.

- If your primary focus is equipment longevity: Prioritize the quality of the PTFE liner to protect the stainless steel shell from the corrosive sulfuric acid solutions.

By using a high-pressure autoclave, you transform a simple heating step into a mechanism for deep structural modification, setting the stage for high-performance activated carbon.

Summary Table:

| Feature | Function | Benefit for Activated Carbon |

|---|---|---|

| Autogenous Pressure | Forces chemical agents into biomass fibers | Ensures deep penetration and uniform pre-carbonization |

| High Temperature | Enables preliminary thermal degradation | Creates critical surface active sites for later activation |

| Stainless Steel Shell | Provides high tensile strength | Safely contains intense internal pressures during heating |

| PTFE Liner | Offers exceptional corrosion resistance | Prevents chemical contamination and protects the vessel |

Elevate Your Material Synthesis with KINTEK’s Precision Engineering

Achieving high-performance activated carbon requires the right environment for hydrothermal treatment. KINTEK provides specialized lab equipment designed to withstand extreme conditions while ensuring consistent, high-quality results.

Why Partner with KINTEK?

- Expert R&D and Manufacturing: Benefit from our deep technical expertise in high-pressure and high-temperature systems.

- Comprehensive Equipment Range: We offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements.

- Tailored Solutions: Whether you are focusing on biomass degradation or advanced pore development, our furnaces are built for precision and durability.

Ready to optimize your hydrothermal and carbonization processes? Contact our specialists today to discuss your project!

Visual Guide

References

- Nokuthula Mekgoe, Kriveshini Pillay. Synergistic electrochemical detection of ciprofloxacin using bismuth vanadate nanocomposite-modified activated carbon derived from banana peel biomass. DOI: 10.1039/d5ma00168d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the technical purpose of drying NaNbO3:Pr3+ precursors at 60 °C? Optimize Your Powder Synthesis

- Why is a blast drying oven required during zeolite modification? Ensure Structural Integrity & Precision

- Why are SiC fragments added in microwave sintering? Boost Heating Uniformity and Prevent Cracks in Porous Ceramics

- What advantages does hydrogen gas-phase pyrolysis offer over inert gas? Unlock Superior Carbon Defunctionalization

- How does the thermal treatment enhance the mechanical properties of AZO and ZnO coatings? Boost Durability & Hardness

- How does a forced-air drying oven contribute to the transformation of GaN precursor resins? Ensure Material Uniformity

- What is the role of high-purity argon gas in ultrafine magnesium powder production? Control Particle Size & Purity

- How is the influence of permeation temperature on steel hardness quantified? Precision Modeling for Plasma Nitriding