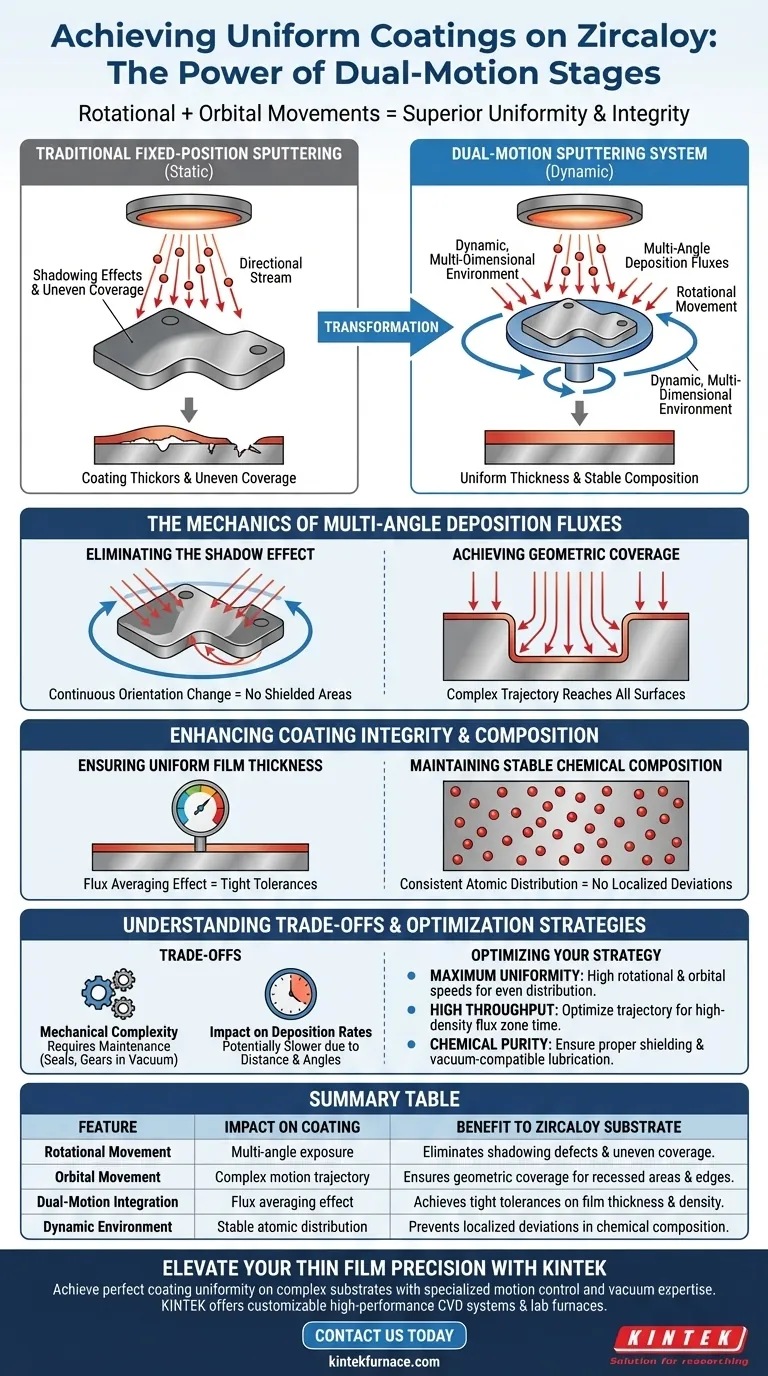

The dual-motion trajectory of the sample stage is the critical factor in achieving coating uniformity on Zircaloy substrates. By combining rotational and orbital movements, the sputtering system exposes the substrate to multi-angle deposition fluxes, which effectively bypasses the limitations of traditional fixed-position sputtering. This process ensures that metal atoms are distributed evenly across all surfaces, resulting in a coating characterized by uniform thickness and a stable chemical composition.

The integration of rotational and orbital movements transforms the deposition process from a static, directional stream into a dynamic, multi-dimensional environment. This ensures that every facet of the Zircaloy substrate receives equal exposure to the material flux, eliminating the "shadowing" defects common in simpler systems.

The Mechanics of Multi-Angle Deposition Fluxes

Eliminating the Shadow Effect

In traditional sputtering, fixed target positions often create "shadows" where certain areas of a complex substrate receive less material than others. By introducing rotational and orbital movements, the substrate constantly changes its orientation relative to the sputtering target. This ensures that no single area is shielded from the incoming metal atoms for the duration of the process.

Achieving Geometric Coverage

Zircaloy substrates often have geometries that require precise coverage to maintain structural integrity. The complex motion trajectory created by the dual-motion stage ensures that deposition flux reaches recessed areas and edges with the same intensity as flat surfaces. This results in a truly isotropic coating layer that adheres consistently to the entire part.

Enhancing Coating Integrity and Composition

Ensuring Uniform Film Thickness

Uniformity in thickness is vital for the performance of Zircaloy, particularly in high-stress or corrosive environments. The continuous movement of the stage averages out the spatial variations in the plasma flux. This averaging effect is what allows manufacturers to achieve tight tolerances on coating thickness across a large batch of samples.

Maintaining Stable Chemical Composition

A stable chemical composition is necessary for the coating to provide reliable protection. Because the substrate is exposed to the deposition flux from multiple angles, the distribution of metal atoms remains consistent throughout the growth of the film. This prevents localized deviations in chemistry that could otherwise lead to premature coating failure.

Understanding the Trade-offs

Mechanical Complexity and Maintenance

While dual-motion stages significantly improve quality, they introduce higher mechanical complexity into the vacuum chamber. The use of rotating seals and gears in a vacuum environment requires more frequent maintenance and monitoring to prevent mechanical failure or contamination.

Impact on Deposition Rates

Introducing orbital and rotational paths can sometimes lead to a lower "net" deposition rate compared to a static substrate positioned directly under a target. The increased distance and varying angles mean that while the coating is more uniform, the time required to reach a specific thickness may be longer.

Optimizing Your Deposition Strategy

To achieve the best results when coating Zircaloy substrates, you must balance the benefits of stage movement with your specific production requirements.

- If your primary focus is Maximum Thickness Uniformity: Utilize the highest available orbital and rotational speeds to ensure the most even distribution of material flux across all substrate surfaces.

- If your primary focus is High Throughput: Optimize the stage trajectory to maximize the time the substrate spends in the high-density flux zone while still maintaining enough movement to prevent shadowing.

- If your primary focus is Chemical Purity: Ensure that the mechanical components of the moving stage are properly shielded and lubricated with vacuum-compatible materials to prevent outgassing.

By mastering the complex interplay of rotational and orbital movements, you ensure that your Zircaloy coatings meet the highest standards of technical excellence and durability.

Summary Table:

| Feature | Impact on Coating | Benefit to Zircaloy Substrate |

|---|---|---|

| Rotational Movement | Multi-angle exposure | Eliminates shadowing defects and uneven coverage. |

| Orbital Movement | Complex motion trajectory | Ensures geometric coverage for recessed areas and edges. |

| Dual-Motion Integration | Flux averaging effect | Achieves tight tolerances on film thickness and density. |

| Dynamic Environment | Stable atomic distribution | Prevents localized deviations in chemical composition. |

Elevate Your Thin Film Precision with KINTEK

Achieving perfect coating uniformity on complex Zircaloy substrates requires more than just standard equipment—it requires specialized motion control and vacuum expertise. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems and lab high-temp furnaces that are fully customizable to your unique research or production needs.

Whether you are refining nuclear-grade materials or advanced alloys, our team provides the technical edge you need to eliminate shadowing and master deposition flux. Contact us today to discover how our tailored solutions can enhance your laboratory's efficiency and coating integrity.

Visual Guide

References

- Yuxin Tang, Dewen Tang. High-Temperature Oxidation Behavior of TiN-, Cr-, and TiN–Cr PVD-Coated Zircaloy 4 Alloy at 1200 °C. DOI: 10.3390/ma18081692

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Molybdenum Vacuum Heat Treat Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What function does a fluidized bed reactor perform in oil sludge pyrolysis? Enhance Thermal Efficiency

- What is the necessity of a laboratory vacuum drying oven for photocatalytic powders? Protect Your Material Integrity

- What is the function of planetary ball mills or industrial mixing granulators prior to RHF? Optimize FMDS Reactivity

- How does a precision temperature-controlled furnace regulate chemical composition in Cu-Cu2O heterostructures?

- Why is aluminum foil used during selenization and carbonization? Unlock Superior ZnSe Nanoparticle Synthesis

- Why is it necessary to thoroughly dry biomass raw materials before starting a pyrolysis experiment? Improve Yields

- What are the primary technical advantages of using stainless steel for the construction of horizontal pyrolysis furnace bodies? Durability and Thermal Precision

- What type of laboratory equipment is utilized for the high-temperature synthesis of g-C3N4? Key Tools for Success