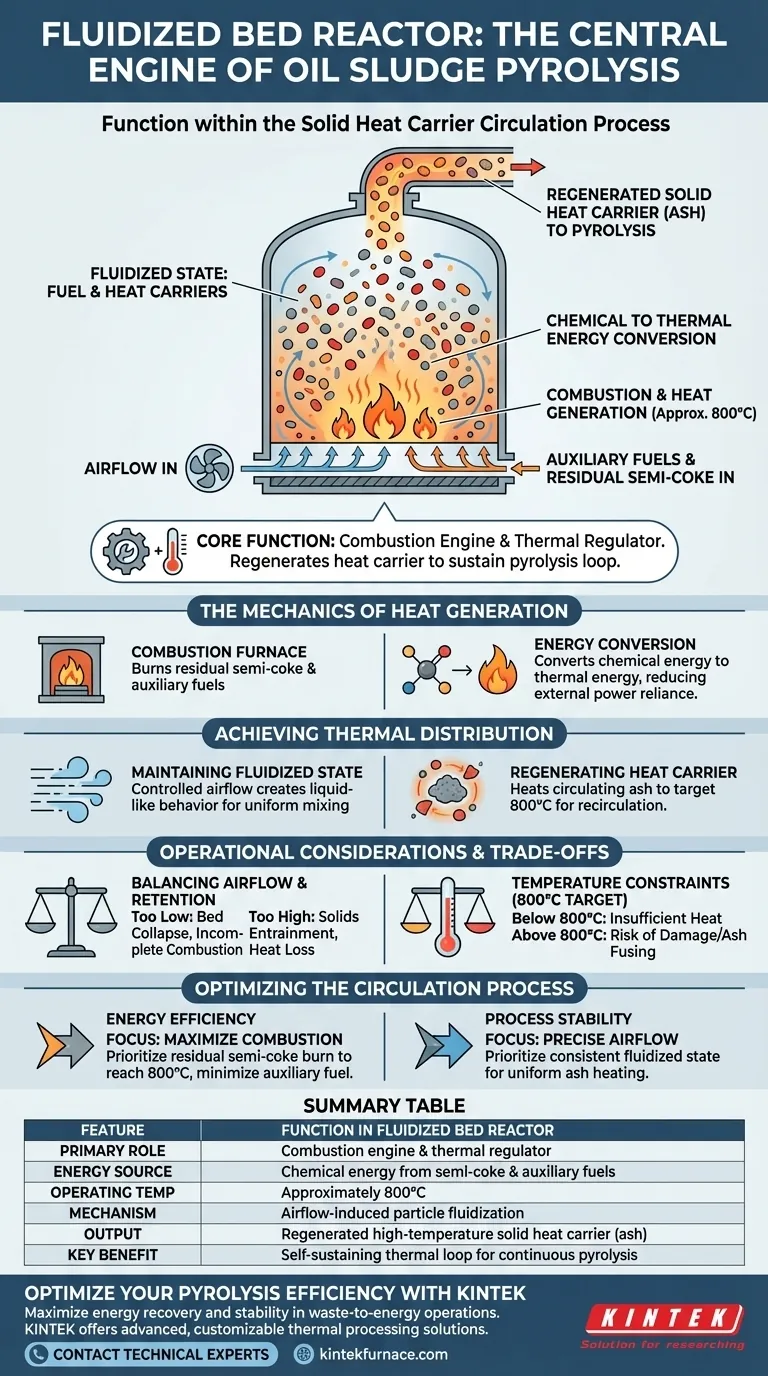

The fluidized bed reactor functions as the central combustion engine and thermal regulator within the solid heat carrier circulation process. It utilizes airflow to suspend semi-coke and heat carrier particles in a fluid-like state, creating an environment optimized for efficient combustion. By converting the chemical energy of residual semi-coke and auxiliary fuels into heat, it raises the temperature of the circulating ash to approximately 800°C to power the pyrolysis reaction.

In this system, the fluidized bed reactor bridges the gap between waste disposal and energy generation. Its core purpose is to regenerate the solid heat carrier, transforming low-value byproducts into the high-temperature thermal energy required to sustain the continuous pyrolysis loop.

The Mechanics of Heat Generation

Acting as the Combustion Furnace

The reactor acts as the primary combustion furnace for the system. It is designed to burn off the residual semi-coke that remains after the initial oil sludge treatment, as well as any auxiliary fuels introduced to the process.

Converting Chemical to Thermal Energy

The fundamental role of this unit is energy conversion. It efficiently transforms the chemical energy stored within the semi-coke and fuels into direct thermal energy. This internal heat generation reduces the system's reliance on external power sources.

Achieving Thermal Distribution

Maintaining a Fluidized State

To ensure efficient burning and heat transfer, the reactor uses controlled airflow. This keeps the solid particles—both fuel and heat carriers—in a fluidized state, causing them to behave like a liquid. This suspension ensures uniform mixing and prevents the formation of hot spots or cold zones.

Regenerating the Heat Carrier

The most critical output of this reactor is the high-temperature solid heat carrier (circulating ash). The combustion process heats this ash to approximately 800°C. Once brought to this target temperature, the ash is recirculated back to the pyrolysis reactor to drive the decomposition of incoming oil sludge.

Operational Considerations and Trade-offs

Balancing Airflow and Retention

Achieving a stable fluidized state requires precise aerodynamic control. If airflow is too low, the bed may collapse, leading to incomplete combustion and uneven heating. Conversely, excessive airflow can entrain solids, blowing the essential heat carriers out of the reactor before they reach the target temperature.

Temperature Constraints

While the target is 800°C, maintaining this specific temperature window is a strict operational constraint. Temperatures dropping below this threshold result in insufficient heat for the pyrolysis reaction. However, significantly exceeding this limit can risk damaging the reactor lining or fusing the ash particles.

Optimizing the Circulation Process

To maximize the effectiveness of the fluidized bed reactor, consider your operational priorities:

- If your primary focus is energy efficiency: Maximize the combustion of residual semi-coke to generate the required 800°C without relying heavily on auxiliary fuels.

- If your primary focus is process stability: Prioritize precise airflow regulation to maintain a consistent fluidized state, ensuring the circulating ash is heated uniformly.

Success in this process depends on treating the reactor not just as a furnace, but as a precise instrument for thermal regeneration.

Summary Table:

| Feature | Function in Fluidized Bed Reactor |

|---|---|

| Primary Role | Combustion engine & thermal regulator |

| Energy Source | Chemical energy from semi-coke & auxiliary fuels |

| Operating Temp | Approximately 800°C |

| Mechanism | Airflow-induced particle fluidization |

| Output | Regenerated high-temperature solid heat carrier (ash) |

| Key Benefit | Self-sustaining thermal loop for continuous pyrolysis |

Optimize Your Pyrolysis Efficiency with KINTEK

Are you looking to maximize energy recovery and process stability in your waste-to-energy operations? KINTEK provides advanced laboratory and industrial solutions designed for high-precision thermal processing. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature furnaces tailored for oil sludge treatment and material research.

Transform your waste disposal into a high-efficiency energy stream. Contact our technical experts today to discover how our high-temperature systems can be customized for your unique laboratory or production needs.

Visual Guide

References

- Zhengyang Zhang, Changtao Yue. Theoretical Calculation of Heat and Material Balance for Oil Sludge Pyrolysis Process by Solid Heat Carrier Method. DOI: 10.3390/en18020329

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is an environmental laboratory chamber equipped with an optical window required for synthesizing Hafnium Carbide?

- What role does a laboratory drying oven play in catalyst supports? Ensure Structural Integrity & High Dispersion

- Why are varied heating rates applied during oil shale pyrolysis? Optimize Kinetics and Technical Validation

- How does a continuous furnace differ from a batch furnace? Optimize Your Heat Treatment Process

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- Why is a high-precision furnace required for carbon aerogel activation? Achieve Optimal Pore Development & Control

- Why is ALD equipment used for rear passivation of silicon solar cells? Optimize Your PERC and TOPCon Efficiency

- What are the advantages of a multimode microwave furnace? Accelerate B-doped SiC Nanowire Synthesis for Higher Yields