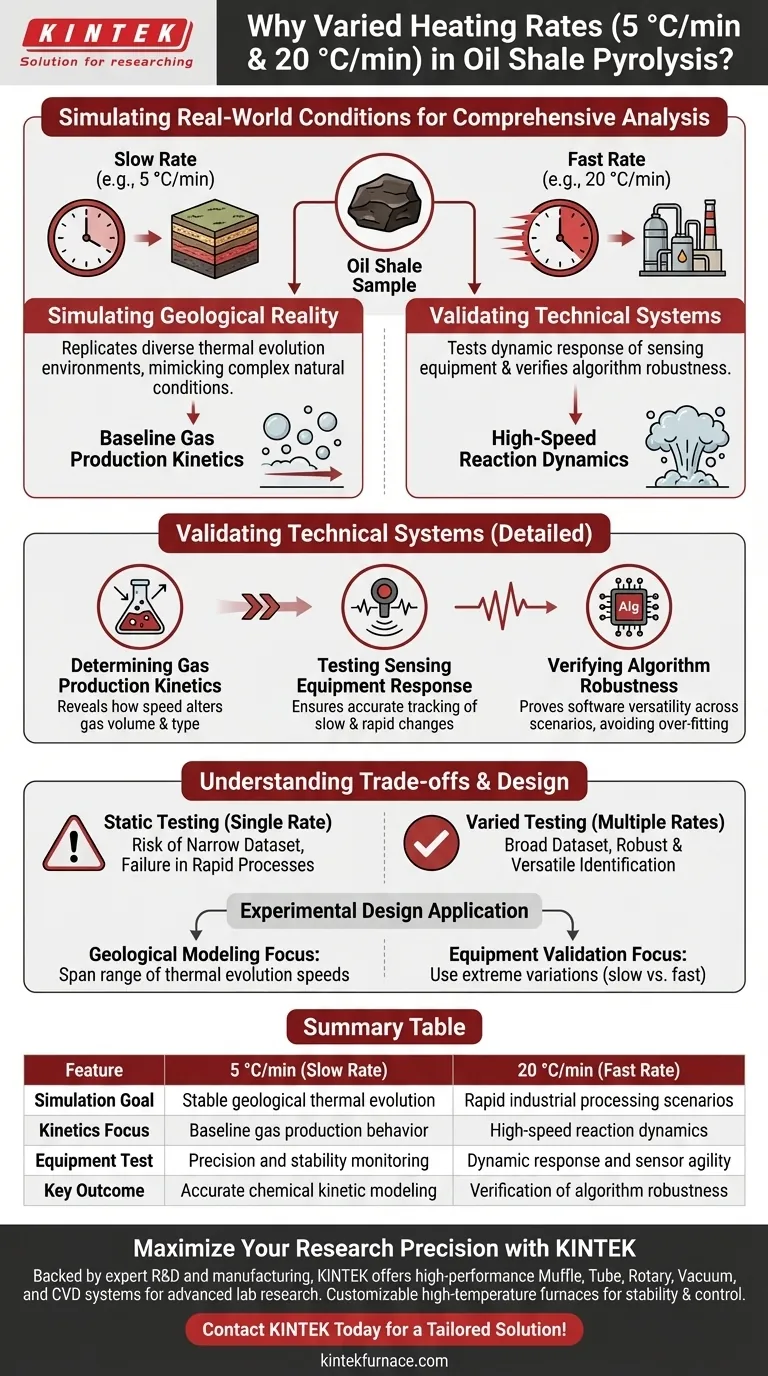

Varied heating rates are applied to simulate real-world conditions. By utilizing different speeds, such as 5 °C/min and 20 °C/min, researchers can replicate the diverse thermal environments found in actual geological formations. This approach allows for a comprehensive analysis of gas production kinetics and validates the reliability of monitoring systems under changing variables.

By testing across a spectrum of heating rates, researchers can bridge the gap between laboratory data and industrial reality, ensuring that identification algorithms remain robust regardless of the processing speed.

Simulating Geological Reality

Replicating Thermal Evolution

In the natural world, geological formations do not undergo thermal changes at a single, static speed.

To understand how oil shale behaves in the ground, researchers must simulate diverse thermal evolution environments.

Applying varied rates allows the laboratory to mimic the complex, non-uniform conditions found in actual geological deposits.

Validating Technical Systems

Determining Gas Production Kinetics

The rate at which heat is applied directly influences the chemical reactions within the shale.

Comparing results from slow (5 °C/min) and fast (20 °C/min) rates helps researchers calculate the kinetics of gas production.

This data reveals how the speed of heating alters the volume and type of gas released.

Testing Sensing Equipment Response

Industrial processing requires monitoring equipment that can handle dynamic changes.

Varied heating rates test the dynamic response of sensing equipment.

This ensures that sensors can accurately track changes whether the reaction is progressing slowly or rapidly.

Verifying Algorithm Robustness

Data collected from sensors is often processed by identification algorithms.

Testing with different rates is crucial for verifying the robustness and versatility of these algorithms.

It proves that the software can correctly identify conditions across varying industrial processing scenarios, rather than being optimized for just one specific speed.

Understanding the Trade-offs

The Risk of Static Testing

Relying on a single heating rate creates a narrow dataset that may not reflect reality.

If an algorithm is only validated at 5 °C/min, it may fail unexpectedly during a rapid industrial process running at 20 °C/min.

Varied testing prevents this "over-fitting" of data, exposing weaknesses in sensing equipment before deployment.

Applying These Principles to Experimental Design

- If your primary focus is Geological Modeling: Ensure your heating rates span the range of thermal evolution speeds found in your target formation to capture accurate behavioral data.

- If your primary focus is Equipment Validation: Use extreme variations in heating rates (slow vs. fast) to stress-test the dynamic response of your sensors and the versatility of your algorithms.

Comprehensive testing across varied rates is the only way to ensure your data is scientifically valid and your technology is industrially viable.

Summary Table:

| Feature | 5 °C/min (Slow Rate) | 20 °C/min (Fast Rate) |

|---|---|---|

| Simulation Goal | Stable geological thermal evolution | Rapid industrial processing scenarios |

| Kinetics Focus | Baseline gas production behavior | High-speed reaction dynamics |

| Equipment Test | Precision and stability monitoring | Dynamic response and sensor agility |

| Key Outcome | Accurate chemical kinetic modeling | Verification of algorithm robustness |

Maximize Your Research Precision with KINTEK

Precision in oil shale pyrolysis requires equipment that can handle diverse thermal profiles. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigors of advanced lab research. Whether you are simulating geological evolution or testing industrial gas kinetics, our customizable high-temperature furnaces provide the stability and control you need.

Ready to elevate your thermal analysis? Contact KINTEK today for a tailored solution that fits your unique experimental needs!

Visual Guide

References

- Yuping Yuan, Zhiyong Chang. Deep Learning Framework for Oil Shale Pyrolysis State Recognition Using Bionic Electronic Nose. DOI: 10.1007/s44196-025-00913-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is an ultra-thin ruthenium buffer layer used for sapphire and Ru50Mo50? Optimize Your Thin Film Quality

- How do microprocessor-controlled electric furnaces ensure the homogeneity of the Se80In5Te6Sb9 alloy?

- How are heat treatment furnaces utilized in the automotive industry? Enhance Component Durability and Performance

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- Why is rapid quenching required during the preparation of amorphous glass fertilizers? Boost Nutrient Solubility

- Why is precise temperature control critical in a calcination furnace for LiMnO2? Achieve High-Purity Crystal Structures

- What is the catalytic mechanism of methane gas conversion in Ni-Co CNT synthesis? Master Carbon Transformation