In the automotive industry, heat treatment furnaces are not merely ovens; they are precision instruments critical for manufacturing strong, durable, and reliable components. They are used to fundamentally alter the properties of metals for high-stress parts like gears, engine components, shafts, and bearings, ensuring they can withstand intense operational demands by enhancing their strength, hardness, and resistance to wear and fatigue.

The core function of heat treatment in automotive manufacturing is to re-engineer a metal's internal crystal structure. This controlled process transforms standard metal parts into high-performance components capable of ensuring the vehicle's safety, efficiency, and longevity.

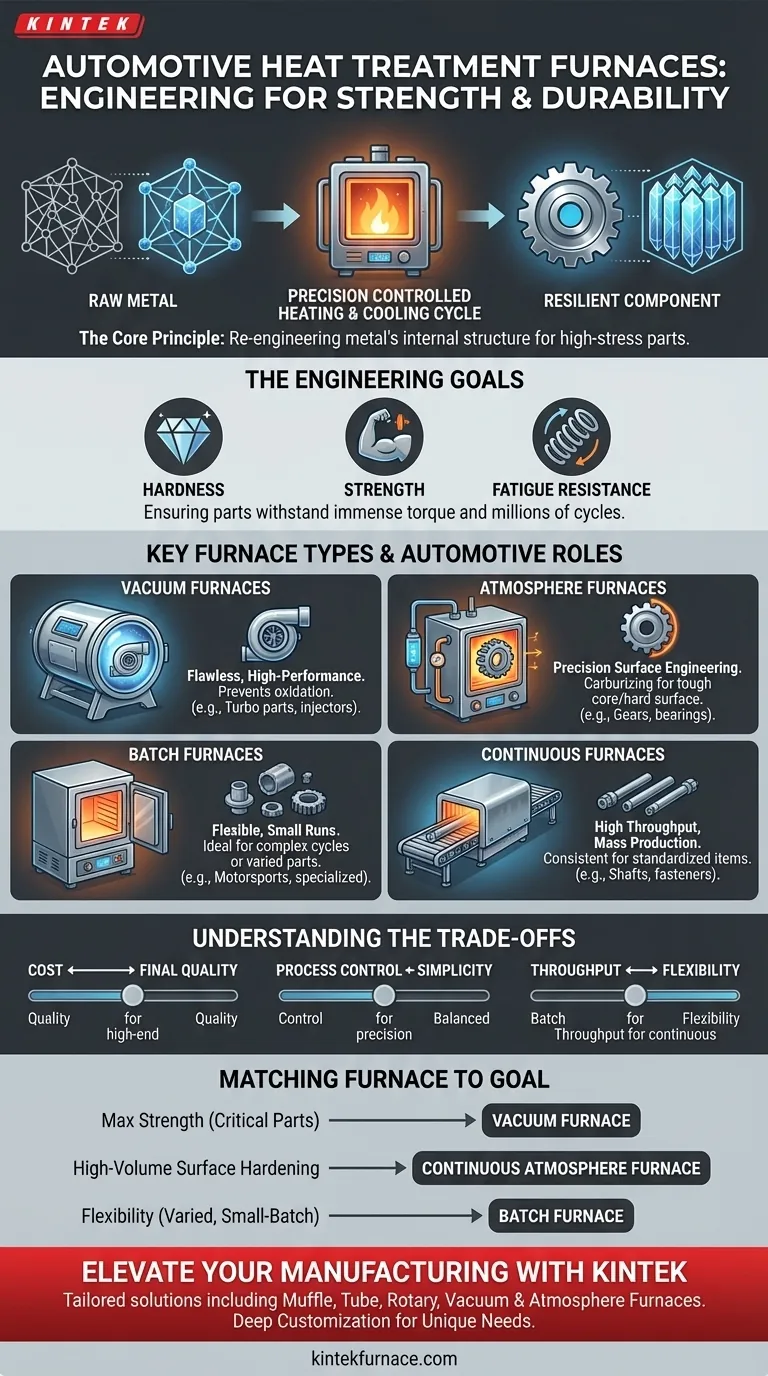

The Core Principle: Why Heat Treatment is Essential

From Raw Metal to Resilient Component

A furnace heats metal to a specific, tightly controlled temperature and holds it for a set duration before cooling it in a calculated manner. This cycle is not simply about heating and cooling; it is a metallurgical process that rearranges the atomic structure of the material.

Without this process, critical parts like transmission gears or engine crankshafts would be far more brittle and wear out quickly, leading to catastrophic failure.

The Engineering Goals

The primary objectives of heat treating automotive parts are to increase hardness, improve strength, and enhance fatigue resistance.

This ensures that a gear tooth can handle immense torque without shearing off and that a bearing can spin millions of times without deforming.

Key Furnace Types and Their Automotive Roles

The choice of furnace depends entirely on the component's requirements, the material being used, and the scale of production.

Vacuum Furnaces: For Flawless, High-Performance Parts

Vacuum furnaces are the gold standard for the most critical automotive components, such as high-performance gears, fuel injectors, and turbocharger parts.

By operating in a near-vacuum, these furnaces prevent any gases from reacting with the metal at high temperatures. This eliminates surface oxidation, resulting in a clean, pristine surface and superior mechanical properties.

Processes like high-pressure gas quenching, performed within a vacuum furnace, provide rapid and uniform cooling, which is essential for achieving maximum hardness and strength in parts subject to extreme stress.

Atmosphere Furnaces: Precision Surface Engineering

Atmosphere furnaces introduce a specific, controlled gas mixture (such as nitrogen, argon, or carbon-rich gases) into the heating chamber.

This method is crucial for surface-hardening processes like carburizing, where carbon is diffused into the surface of steel parts like gears. This creates a component with an incredibly hard, wear-resistant surface while maintaining a softer, tougher core that can absorb shock.

Batch vs. Continuous Furnaces: A Matter of Scale

Batch furnaces process one load or "batch" of parts at a time. This makes them highly flexible and ideal for smaller production runs, specialized components (like for motorsports), or parts with complex heating cycles.

Continuous furnaces, by contrast, move parts through various heating and cooling zones on a conveyor belt. They are the workhorses of high-volume manufacturing, used for standardized items like shafts and fasteners where consistency and throughput are paramount.

Understanding the Trade-offs

Choosing a heat treatment process involves balancing performance requirements with operational realities. No single method is universally superior.

Cost vs. Final Quality

Vacuum furnaces produce parts with exceptional quality and performance, but their initial investment and operational costs are significantly higher.

For less critical components, atmosphere or simple batch furnaces can provide the necessary properties in a more cost-effective manner.

Process Control vs. Simplicity

Achieving precise metallurgical properties requires sophisticated process control. Vacuum and atmosphere furnaces demand advanced sensor arrays and automated systems to manage temperature, time, and gas composition accurately.

Simpler furnace types may be easier to operate but offer less control, which may be insufficient for parts with tight engineering tolerances.

Throughput vs. Flexibility

Continuous furnaces are built for mass production, offering unmatched throughput for a single type of part. However, they are highly inflexible and changing the process for a new part is a major undertaking.

Batch furnaces provide the opposite: lower overall throughput but the ability to easily switch between different parts and treatment cycles, making them ideal for just-in-time manufacturing or diverse product lines.

Matching the Furnace to the Automotive Goal

Your selection should be directly guided by the end-use application of the component and your production strategy.

- If your primary focus is maximum strength and fatigue life for critical components: A vacuum furnace with high-pressure gas quenching is the definitive choice for its clean processing and superior results.

- If your primary focus is high-volume production of parts needing surface hardening: A continuous atmosphere furnace is the most efficient solution for processes like carburizing.

- If your primary focus is flexibility for varied, smaller-batch components: A batch furnace provides the necessary versatility to handle diverse parts and treatment requirements effectively.

Ultimately, selecting the right heat treatment process is a foundational engineering decision that dictates the safety, reliability, and performance of the final vehicle.

Summary Table:

| Furnace Type | Key Features | Common Automotive Applications |

|---|---|---|

| Vacuum Furnace | Prevents oxidation, superior mechanical properties, high-pressure gas quenching | High-performance gears, fuel injectors, turbocharger parts |

| Atmosphere Furnace | Controlled gas mixtures, surface hardening (e.g., carburizing) | Gears, shafts, bearings requiring wear-resistant surfaces |

| Batch Furnace | Flexible, ideal for small runs and complex cycles | Specialized components, motorsports parts, varied product lines |

| Continuous Furnace | High throughput, consistent for mass production | Standardized items like shafts and fasteners |

Ready to elevate your automotive manufacturing with precision heat treatment solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production needs, enhancing component strength, durability, and performance. Contact us today to discuss how our tailored solutions can drive your success in the automotive industry!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control