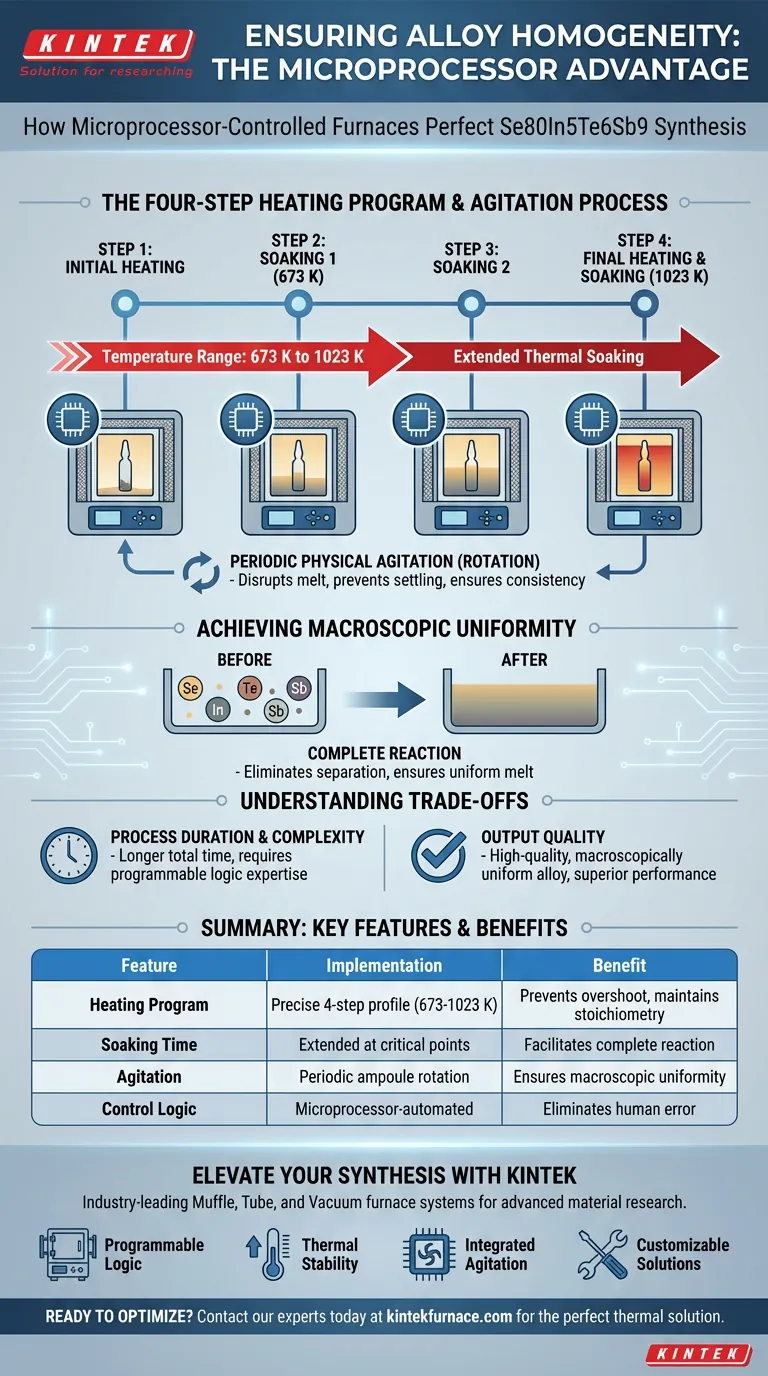

Microprocessor-controlled electric furnaces ensure homogeneity by executing a rigorous, four-step heating program that precisely manages temperatures between 673 K and 1023 K. This automated process combines extended thermal soaking times with periodic physical agitation to force the complete reaction and integration of the constituent elements.

The synergy between precise, multi-stage temperature control and mechanical rotation is critical for complex alloys like Se80In5Te6Sb9. This approach facilitates the complete reaction of chalcogenide elements, eliminating separation and ensuring a macroscopically uniform melt.

The Mechanics of Thermal Control

The Four-Step Heating Program

To synthesize a complex alloy, simple heating is insufficient. The microprocessor executes a precise four-step heating profile, rather than a single linear ramp.

Temperature Range and Regulation

The system manages a rigorous thermal treatment profile, typically operating within a specific range of 673 K to 1023 K. The microprocessor ensures that the temperature remains stable at each specific stage, preventing thermal overshoot that could damage the stoichiometry.

Enabling Complete Reaction

The primary goal of this controlled heating is to facilitate extended soaking times at critical temperature points. This duration allows the chalcogenide elements to undergo a complete reaction, which is essential for the structural integrity of the final alloy.

Achieving Macroscopic Uniformity

Periodic Physical Agitation

Thermal control alone cannot guarantee that the elements mix evenly throughout the container. The furnace incorporates periodic physical agitation or rotation of the ampoule during the heating process.

Enhancing Melt Homogeneity

This mechanical motion disrupts the melt, preventing heavier elements from settling and ensuring the mixture is consistent throughout. The combination of heat and motion significantly enhances the macroscopic homogeneity of the alloy melt.

Understanding the Trade-offs

Process Duration vs. Output Quality

The rigorous nature of a four-step program with extended soaking times inherently increases the total processing time. While this ensures high quality, it significantly reduces the throughput speed compared to simpler, less precise heating methods.

Equipment Complexity

Microprocessor-controlled systems are more complex to operate and maintain than standard furnaces. The necessity for programmable logic to handle precise agitation and multi-stage heating requires a higher level of operator expertise and equipment calibration.

Making the Right Choice for Your Synthesis

To achieve the best results with Se80In5Te6Sb9 or similar chalcogenide glasses, align your process with your specific quality requirements.

- If your primary focus is absolute homogeneity: Prioritize the use of a furnace with integrated, programmable rotation to ensure the melt is physically agitated throughout the heating steps.

- If your primary focus is reaction completeness: Ensure your programming allows for extended soaking times at the upper limits of the temperature range (near 1023 K).

By automating the delicate balance of heat and motion, you transform raw elements into a uniform, high-performance alloy.

Summary Table:

| Feature | Implementation in Se80In5Te6Sb9 Synthesis | Benefit to Alloy Quality |

|---|---|---|

| Heating Program | Precise 4-step profile (673 K to 1023 K) | Prevents thermal overshoot; maintains stoichiometry |

| Soaking Time | Extended duration at critical temperature points | Facilitates complete reaction of chalcogenide elements |

| Agitation | Periodic physical rotation of the ampoule | Prevents element settling; ensures macroscopic uniformity |

| Control Logic | Microprocessor-automated regulation | Eliminates human error in complex thermal profiles |

Elevate Your Material Synthesis with KINTEK

Achieving perfect homogeneity in complex chalcogenide alloys like Se80In5Te6Sb9 requires more than just heat—it requires precision. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems specifically designed for advanced material research.

Backed by expert R&D and manufacturing, our systems offer the programmable logic and thermal stability needed for multi-stage heating and integrated agitation. Whether you need a standard solution or a customizable high-temp furnace tailored to your unique stoichiometry, KINTEK ensures your lab achieves superior melt uniformity and reaction completeness.

Ready to optimize your alloy production? Contact our technical experts today to find the perfect thermal solution for your research.

Visual Guide

References

- Studies on phase change Se80In5Te6Sb9 thin films by -irradiation for optoelectronic devices. DOI: 10.56975/jetir.v12i1.563335

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does precise heating rate control affect nitrogen-doped carbon synthesis? Master Thermal Ramp for Quality Materials

- What is the role of a rotary evaporator in the extraction of isopulegyl acetate? Protect Purity and Stability

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development

- How does a high-sensitivity non-contact microphone assist in detecting cracks during the solidification of molten slag?

- What type of furnace was chosen for annealing silicon-based materials and what were the key requirements? Discover the Ideal Solution for Precise Heat Treatment

- What is the function of placing a Nickel Mesh in a reactor? Maximizing Heat in Nickel-Hydrogen Systems

- What are the benefits of applying secondary artificial aging heat treatment to aluminum alloy parts? Boost Yield Strength

- What is the primary function of a vacuum oven for Mo-based catalyst precursors? Ensure Purity & Pore Integrity