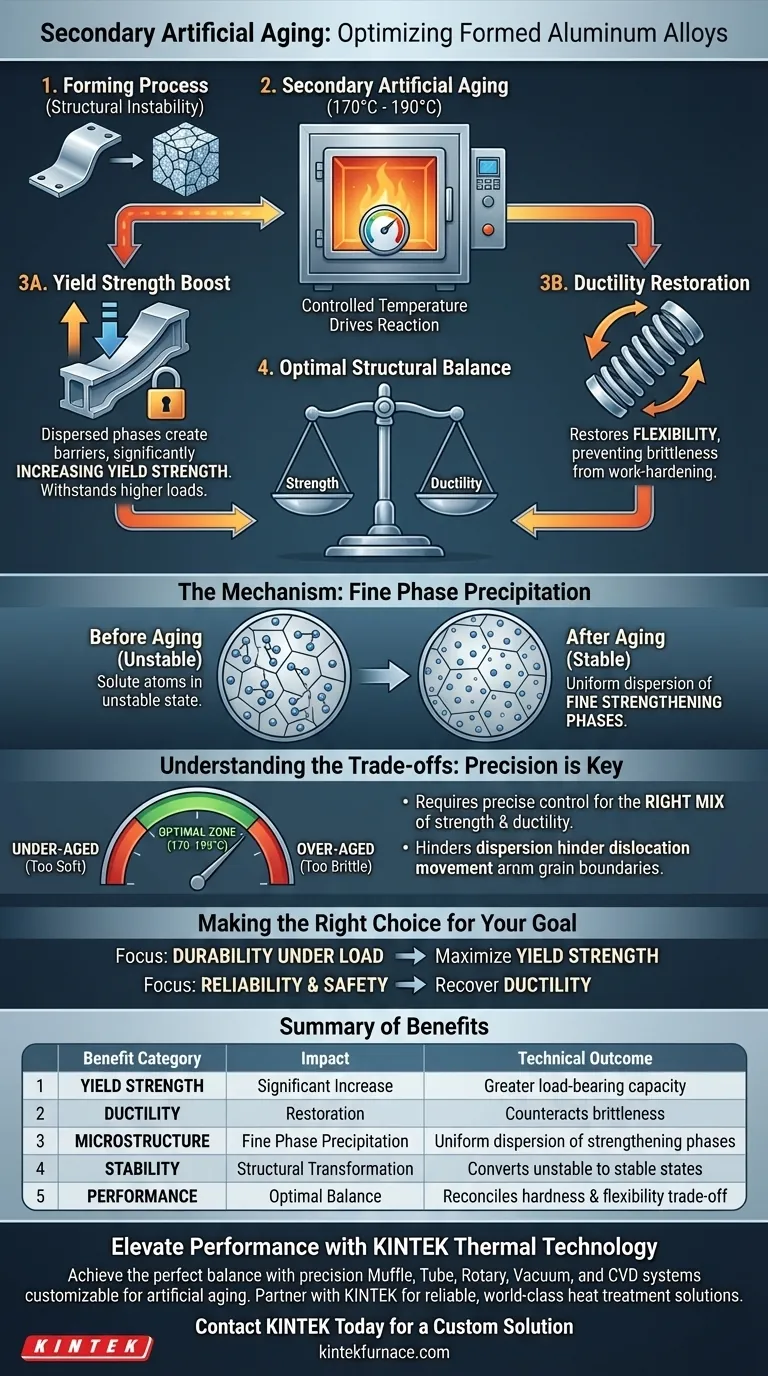

Secondary artificial aging is a critical thermal process designed to optimize the mechanical performance of aluminum alloy parts after they have been formed. By subjecting the material to controlled temperatures, typically between 170°C and 190°C, you leverage the structural instability created during deformation to trigger the precipitation of fine strengthening phases within the metal's matrix.

The core value of this treatment lies in its ability to reconcile conflicting mechanical properties. It utilizes the energy from the forming process to drive a reaction that simultaneously restores lost ductility and significantly boosts yield strength, resulting in a final product with an optimal structural balance.

The Mechanism of Improvement

To understand the benefits, you must first understand how the process manipulates the alloy's internal structure.

Leveraging Structural Instability

When an aluminum alloy is formed or deformed, the material enters a state of structural instability.

Secondary artificial aging takes advantage of this state. The treatment does not simply heat the metal; it uses this pre-existing instability to accelerate favorable microstructural changes.

Fine Phase Precipitation

The furnace-driven heat triggers the movement of solute atoms.

These atoms precipitate out of the solution to form fine, dispersed strengthening phases throughout the matrix. This uniform dispersion is the fundamental driver behind the enhanced mechanical performance of the finished part.

Key Performance Benefits

The practical outcome of this microstructural change is a dual improvement in the part's physical capabilities.

Significant Increase in Yield Strength

The primary structural benefit is hardening.

The dispersed phases create barriers to dislocation movement, which significantly increases the yield strength of the part. This ensures the component can withstand higher loads without permanent deformation.

Restoration of Ductility

Forming processes generally reduce a material's ductility, making it brittle.

Secondary aging compensates for this loss. It restores a degree of flexibility to the material, preventing the brittleness often associated with work-hardened parts.

Understanding the Trade-offs

While secondary aging provides significant enhancements, it is defined by the need for balance rather than maximization of a single trait.

The "Optimal Balance" Constraint

The goal of this process is an optimal balance of properties, not necessarily the absolute maximum of one specific metric at the expense of all others.

Achieving the right mix of strength and ductility requires precise temperature control (e.g., 170°C vs. 190°C). Deviating from these parameters could result in a part that is either too brittle (over-aged) or too soft (under-aged).

Making the Right Choice for Your Goal

Deciding to implement secondary artificial aging depends on the performance requirements of your specific component.

- If your primary focus is Durability under Load: This treatment is essential to maximize yield strength and prevent deformation during service.

- If your primary focus is Reliability and Safety: The process is critical for recovering ductility, ensuring the part can absorb energy without fracturing unexpectedly.

Ultimately, secondary artificial aging transforms a formed part from a structurally unstable state into a high-performance component with a unified, stable microstructure.

Summary Table:

| Benefit Category | Impact of Secondary Aging | Technical Outcome |

|---|---|---|

| Yield Strength | Significant Increase | Greater load-bearing capacity without deformation |

| Ductility | Restoration | Counteracts brittleness from forming processes |

| Microstructure | Fine Phase Precipitation | Uniform dispersion of strengthening phases |

| Stability | Structural Transformation | Converts unstable formed states into stable states |

| Performance | Optimal Balance | Reconciles the trade-off between hardness and flexibility |

Elevate Your Aluminum Component Performance

Achieving the perfect balance of yield strength and ductility requires the precision that only industry-leading thermal technology can provide. KINTEK empowers your lab and production line with cutting-edge Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the exacting temperature profiles required for secondary artificial aging.

Backed by expert R&D and world-class manufacturing, we provide the tools you need to transform structurally unstable parts into high-performance materials. Don’t settle for sub-optimal mechanical properties—partner with KINTEK for reliable, precision-engineered heat treatment solutions.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Łukasz Kuczek, Ryszard Sitek. Influence of Heat Treatment on Properties and Microstructure of EN AW-6082 Aluminium Alloy Drawpieces After Single-Point Incremental Sheet Forming. DOI: 10.3390/app15020783

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the objective of coordinating mechanical stirring and heating for perovskite slurries? Achieve Homogeneity

- Why is a laboratory electric blast drying oven necessary for determining the water absorption rate of mortar?

- What is the function of a constant temperature blast drying oven? Achieve Uniform Chemical Activation and Porosity

- What is the role of a fixed-bed reactor in the slow pyrolysis process? Engineering High-Quality Biochar Production

- What is the core role of a high-pressure autoclave in the synthesis of LTA zeolites? Achieve Precise Crystal Growth

- What role does microwave heating equipment play in solder-free VIG? Boost Efficiency with Edge Fusion Technology

- What role does an industrial oven play in the pretreatment of oil palm shell for biochar? Ensure Peak Biomass Quality

- How does the use of carbon dioxide and a flow meter impact the physical activation of biochar? Master Pore Development