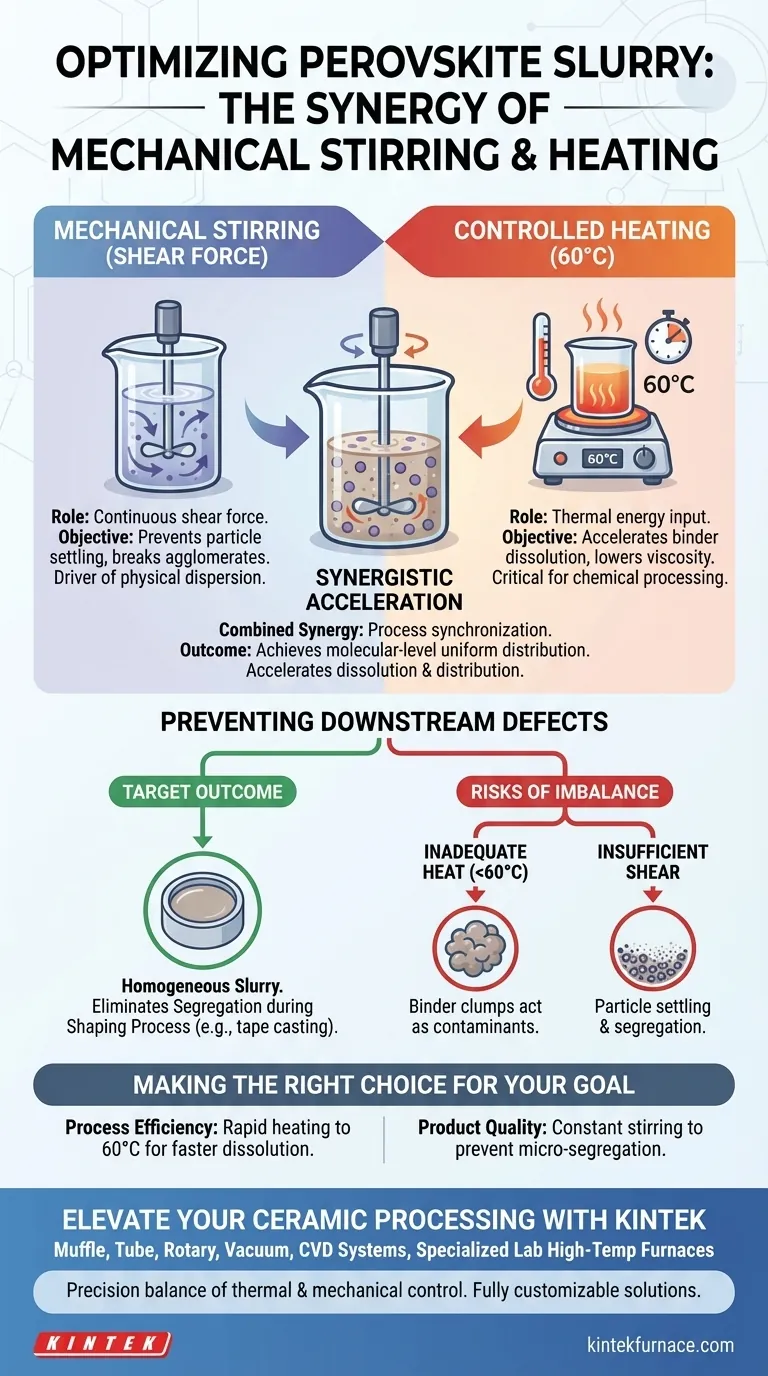

The primary objective of coordinating mechanical stirring with heating is to achieve a molecular-level uniform distribution of components. By applying continuous shear force while maintaining the slurry at approximately 60 °C, you accelerate the dissolution of polymer binders. This simultaneous mechanical and thermal input prevents component segregation, ensuring the slurry is stable and ready for subsequent shaping.

The synergy between mechanical shear and controlled heating is essential for fully dissolving binders and dispersing solid particles, effectively eliminating the risk of segregation during the shaping process.

The Mechanics of Slurry Homogenization

The Role of Continuous Shear Force

Mechanical stirring is the driver of physical dispersion. It provides the necessary shear force to break down agglomerates and keep solid-phase particles suspended.

Without this continuous motion, denser perovskite particles would naturally settle. The shear force combats gravity and inter-particle attraction, forcing the solids to remain suspended within the liquid medium.

The Function of Controlled Heating

Heating equipment is used to maintain the slurry at a specific target temperature, typically around 60 °C. This thermal energy is not arbitrary; it is critical for the chemical processing of the organic components.

Elevated temperatures lower the viscosity of the liquid medium and increase the solubility of the polymer binders and dispersants. This thermal environment allows these binders to dissolve more rapidly and completely than they would at room temperature.

Synergistic Acceleration

When shear force and heat are combined, the preparation process becomes significantly more efficient. The heat softens and dissolves the binder, while the stirring immediately disperses that dissolved binder throughout the mix.

This synergy accelerates the entire dissolution process. It ensures that the binder coats the solid particles evenly, creating a consistent network structure throughout the slurry.

Preventing Downstream Defects

Eliminating Component Segregation

The ultimate goal of this coordination is to prevent component segregation. Segregation occurs when the solid particles separate from the liquid or binder matrix, leading to weak spots or density gradients in the final ceramic.

By achieving a molecular-level uniform distribution, the slurry becomes a cohesive unit. This uniformity is vital for the "shaping process," where the slurry is formed into its final geometry (such as in tape casting or spin coating).

Understanding the Risks of Imbalance

The Consequence of Inadequate Heat

If the temperature drops significantly below 60 °C, the polymer binders may fail to dissolve completely.

This results in a heterogeneous mixture where binder clumps effectively act as contaminants rather than stabilizing agents.

The Consequence of Insufficient Shear

Even with perfect heating, a lack of mechanical shear allows gravity to take over.

The solid particles will begin to settle or segregate from the liquid phase. Once segregation begins, it is difficult to reverse, often rendering the slurry unsuitable for high-precision ceramic manufacturing.

Making the Right Choice for Your Goal

To ensure the quality of your perovskite ceramic slurry, you must view stirring and heating as inseparable variables.

- If your primary focus is Process Efficiency: Ensure your heating equipment can rapidly reach and stabilize at 60 °C to minimize the time required for binder dissolution.

- If your primary focus is Product Quality: prioritize constant, uninterrupted mechanical stirring to prevent even micro-levels of particle segregation prior to the shaping phase.

Success depends on the precise synchronization of thermal energy to dissolve binders and mechanical energy to distribute them.

Summary Table:

| Parameter | Role in Slurry Preparation | Key Objective |

|---|---|---|

| Mechanical Stirring | Continuous shear force | Prevents particle settling & breaks agglomerates |

| Controlled Heating (60°C) | Thermal energy input | Accelerates binder dissolution & lowers viscosity |

| Combined Synergy | Process synchronization | Achieves molecular-level uniform distribution |

| Target Outcome | Homogeneous slurry | Eliminates segregation during the shaping process |

Elevate Your Ceramic Processing with KINTEK

Precision in perovskite preparation requires the perfect balance of thermal and mechanical control. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique research or production needs.

Ready to eliminate component segregation and ensure superior material stability? Contact our technical experts today to find the ideal heating and mixing solution for your laboratory.

Visual Guide

References

- Mathias Pein, Christian Sattler. Thermochemical Oxygen Pumping with Perovskite Reticulated Porous Ceramics for Enhanced Reduction of Ceria in Thermochemical Fuel Production. DOI: 10.1002/aenm.202304454

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do thermal systems reveal anti-spalling mechanisms in CDE concrete? Explore Advanced Material Resilience

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- Why is it necessary to use a vacuum drying oven for porous graphene cathodes? Ensure Peak Battery Performance

- Why is a drying oven with precise temperature control necessary for NiO-CGO anode supports? Ensure Cell Integrity

- What causes large-scale MgO·Al2O3 inclusions in superalloys? Expert Guide to Formation & Prevention

- How does nano-MgO particle size influence sulfur doping in activated carbon? Optimize Doping for High-Performance Lab Materials

- What are the advantages of Spark Plasma Sintering (SPS) for diffusion bonding? Precision in Atomic Diffusion

- What is the function of a forced air drying oven for biochar? Optimize Moringa Oleifera Shell Pre-treatment