At its core, selecting a heat treatment furnace involves choosing between types based on operational scale and the level of atmospheric control required. The main categories include batch furnaces like muffle and retort furnaces, continuous-style tube furnaces, and highly specialized atmosphere and vacuum furnaces, each designed for specific material processing goals in laboratory and industrial settings.

The choice of a heat treatment furnace is not about finding the "best" one, but about precisely matching the furnace's capabilities—particularly its control over the processing atmosphere and its physical configuration—to the specific requirements of your material and desired outcome.

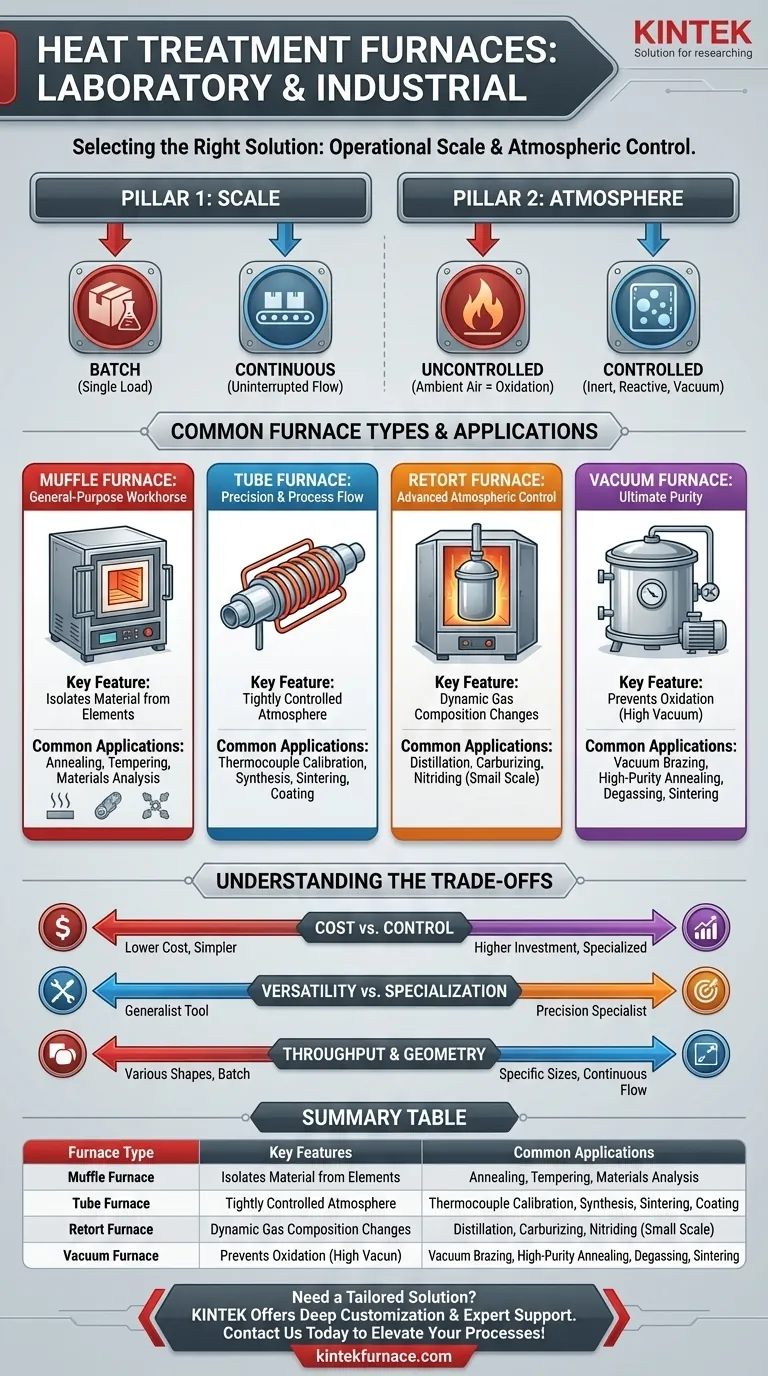

The Two Pillars of Furnace Selection: Scale and Atmosphere

Before diving into specific furnace types, it's essential to understand the two fundamental principles that guide selection: how you process material (scale) and the environment you process it in (atmosphere).

Batch vs. Continuous Processing

A batch furnace processes a single, fixed load of material at a time. This is ideal for research, small production runs, or when process parameters change frequently. Most laboratory furnaces are batch-type.

A continuous furnace processes material in an uninterrupted flow. This design is built for high-volume, standardized industrial production where consistency and throughput are paramount.

The Critical Role of the Atmosphere

The "atmosphere" inside the furnace is the gaseous environment surrounding the material being heated. Controlling this is often the most critical factor in a heat treatment process.

An uncontrolled atmosphere (like ambient air) will cause oxidation and other unwanted chemical reactions at high temperatures. Specialized furnaces are designed to replace the air with inert gases, reactive gases, or a vacuum to achieve a specific result.

Common Furnace Types and Their Applications

With the concepts of scale and atmosphere in mind, we can now examine the specific furnace types commonly used in labs and specialized industrial facilities.

Muffle Furnaces: The General-Purpose Workhorse

A muffle furnace is defined by its design, which uses a chamber (the "muffle") to isolate the material being heated from the heating elements. This prevents contamination from combustion byproducts or electrical discharge.

These furnaces are the versatile backbone of many labs. They are excellent for general-purpose applications like annealing, tempering, and materials analysis where a clean heating environment in ambient air or a simple gas purge is sufficient.

Tube Furnaces: For Precision and Process Flow

A tube furnace uses a cylindrical chamber, typically made of ceramic or alloy, around which heating elements are placed. Their shape makes them exceptionally versatile for handling small or uniquely shaped samples.

The key advantage of a tube furnace is its suitability for creating a tightly controlled atmosphere. The tube can be easily sealed and purged with inert or reactive gases. This makes them indispensable for thermocouple calibration, materials synthesis, sintering, and coating applications.

Retort Furnaces: For Advanced Atmospheric Control

A retort furnace takes atmospheric control a step further. It features a sealed container (the "retort") that holds the material, which is then placed inside the heated furnace chamber.

This separation allows for extremely precise control over the atmosphere, including the ability to change gas compositions during a single heating cycle. They are primarily used for complex processes like the distillation of substances, carburizing, or nitriding on a smaller scale.

Vacuum Furnaces: For Ultimate Purity

A vacuum furnace is the ultimate solution for preventing atmospheric contamination. By removing the air to create a vacuum, it eliminates the possibility of oxidation and other gas-phase reactions.

This makes them essential for high-temperature processes involving reactive metals and advanced materials. Common applications include vacuum brazing, high-purity annealing, degassing, and the sintering of specialty ceramics and powdered metals.

Understanding the Trade-offs

Choosing a furnace involves balancing capability with complexity and cost. There is no single solution that fits all needs.

Cost vs. Control

The level of atmospheric control directly impacts cost and complexity. A simple muffle furnace is relatively inexpensive and easy to operate. In contrast, a high-vacuum furnace is a significant investment requiring specialized knowledge and maintenance.

Versatility vs. Specialization

A muffle furnace is a generalist tool, capable of handling many different tasks adequately. A retort or vacuum furnace is a specialist, designed to perform a narrower range of tasks with exceptional precision.

Throughput and Geometry

The physical design of the furnace dictates the size, shape, and quantity of material you can process. A box-style muffle furnace can handle various shapes, while a tube furnace is better suited for powders, wires, or small, uniform parts that can fit within the tube's diameter.

Making the Right Choice for Your Goal

Your final decision must be driven by the specific demands of your process.

- If your primary focus is general-purpose lab heating and analysis: A muffle furnace provides the best balance of simplicity, cost, and a clean heating environment.

- If your primary focus is process versatility with controlled atmospheres: A tube furnace is the ideal choice for its ability to handle various processes from synthesis to testing.

- If your primary focus is preventing all oxidation and contamination at high temperatures: A vacuum furnace is the only technology that can meet this requirement.

- If your primary focus is complex processes requiring dynamic atmospheric changes: A retort furnace offers the specialized control needed for these advanced applications.

Ultimately, understanding the interplay between your material, your process, and the furnace's capabilities is the key to making an informed and effective decision.

Summary Table:

| Furnace Type | Key Features | Common Applications |

|---|---|---|

| Muffle Furnace | General-purpose, clean heating, batch processing | Annealing, tempering, materials analysis |

| Tube Furnace | Cylindrical chamber, controlled atmosphere, versatile | Thermocouple calibration, synthesis, sintering |

| Retort Furnace | Sealed retort, dynamic atmosphere control, precise | Distillation, carburizing, nitriding |

| Vacuum Furnace | Vacuum environment, prevents oxidation, high purity | Vacuum brazing, annealing, degassing |

Struggling to select the perfect heat treatment furnace for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements, enhancing efficiency and results. Contact us today to discuss how our tailored furnace solutions can elevate your processes—reach out via our contact form for expert guidance and support!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis