Spark Plasma Sintering (SPS) fundamentally outperforms traditional diffusion bonding processes by utilizing pulsed DC current to generate heat directly within the material. This method, often combined with mechanical pressure, achieves full atomic diffusion at the interface in a fraction of the time required by conventional external heating methods, significantly lowering overall energy consumption.

The core value of SPS lies in its ability to decouple densification from prolonged thermal exposure. By achieving rapid consolidation at lower effective temperatures, SPS preserves the critical microstructure and properties of the base materials—such as diamond or fine-grain ceramics—that would otherwise degrade under traditional sintering conditions.

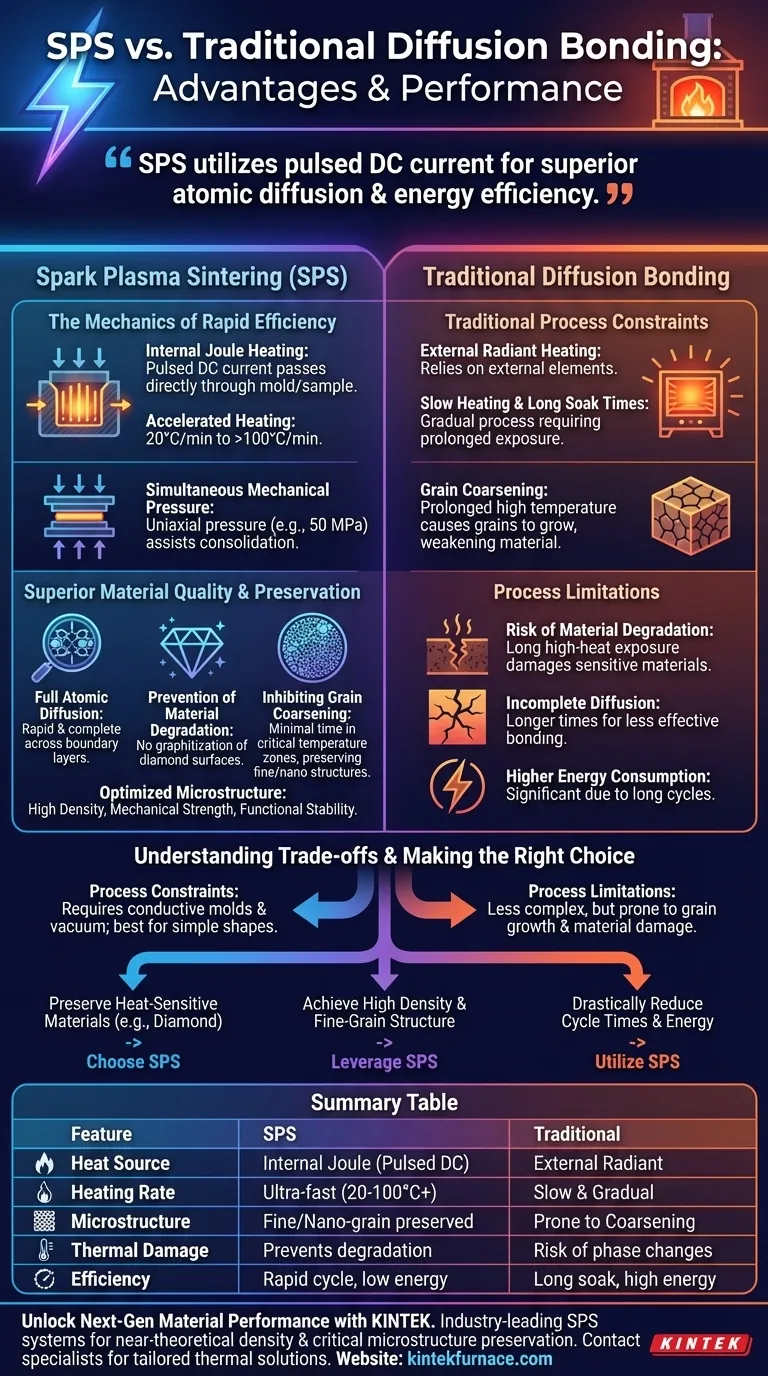

The Mechanics of Rapid Efficiency

Internal Heat Generation

Unlike traditional furnaces that rely on radiant heat from external elements, SPS employs Joule heating. This occurs when a pulsed electric current is passed directly through the mold or the conductive sample itself.

Accelerated Heating Rates

Because the heat is generated internally, the system achieves rapid temperature increases. While specific rates depend on the material, the process supports heating rates significantly higher than conventional methods, ranging from 20 °C/min to over 100 °C/min.

Simultaneous Mechanical Pressure

The application of uniaxial or axial pressure (e.g., 50 MPa) during the heating phase is a critical differentiator. This pressure assists in the physical consolidation of the powder or bonding interface, allowing densification to occur at lower temperatures.

Superior Material Quality and Preservation

Achieving Full Atomic Diffusion

The primary advantage of SPS in diffusion bonding is the quality of the interface. The combination of heat and pressure facilitates full atomic diffusion across the boundary layers extremely quickly.

Prevention of Material Degradation

Traditional processes often require long "soak" times at high heat, which can damage sensitive materials. SPS minimizes this risk; for example, it effectively prevents the graphitization of diamond surfaces, thereby preserving the thermal properties of the base material.

Inhibiting Grain Coarsening

Prolonged exposure to high temperatures typically causes grains to grow (coarsen), which weakens the material. The high-speed nature of SPS minimizes the time spent in these critical temperature zones, effectively inhibiting grain growth.

Optimized Microstructure

By restricting grain growth, SPS produces materials with fine-grained, nanometer, or micrometer structures. This directly translates to superior physical properties, such as:

- High Density: Near-theoretical density is achieved rapidly.

- Mechanical Strength: Finer grains result in harder, stronger composites (e.g., Mo-Cr-Y or ZnS ceramics).

- Functional Stability: It enhances properties like optical translucency in ceramics and piezoelectric stability in Barium Titanate.

Understanding the Trade-offs

Process Constraints

While SPS offers superior material properties, it is generally a more complex process than atmospheric sintering. It relies heavily on conductive molds (typically graphite) and requires a vacuum or controlled atmosphere to manage the plasma discharge effects effectively.

Geometry Limitations

The requirement for applying high uniaxial pressure during the process generally limits the complexity of the shapes that can be produced. Unlike free-sintering methods, SPS is best suited for simple geometries like discs, cylinders, or flat plates where pressure can be applied uniformly.

Making the Right Choice for Your Project

The decision to use SPS should be driven by the specific sensitivity of your materials and your performance requirements.

- If your primary focus is preserving heat-sensitive materials: Choose SPS to minimize thermal exposure and prevent phase degradation, such as the graphitization of diamond.

- If your primary focus is mechanical or optical performance: Leverage SPS to achieve high density while maintaining a fine-grain structure, which enhances hardness and translucency.

- If your primary focus is process efficiency: Utilize SPS to drastically reduce cycle times through rapid Joule heating and lower overall energy consumption.

SPS is the definitive choice when the structural integrity of the interface and the preservation of microscopic material properties are as critical as the bond itself.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Diffusion Bonding |

|---|---|---|

| Heat Source | Internal Joule Heating (Pulsed DC) | External Radiant Heating |

| Heating Rate | Ultra-fast (20°C/min to 100°C+) | Slow and Gradual |

| Microstructure | Preserves Fine/Nano-grain structures | Prone to Grain Coarsening |

| Thermal Damage | Prevents degradation (e.g. Diamond) | Risk of material phase changes |

| Efficiency | Rapid cycle times & low energy | Long soak times & high energy |

Unlock Next-Gen Material Performance with KINTEK

Don’t let traditional sintering limitations degrade your material’s potential. KINTEK provides industry-leading Spark Plasma Sintering (SPS) systems designed to achieve near-theoretical density while preserving critical microstructures. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your lab's unique high-temperature needs.

Ready to accelerate your research and bonding efficiency?

Contact our specialists today to discover how our tailored thermal solutions can transform your material science outcomes.

Visual Guide

References

- Ying Zhou, Degan Xiong. An Investigation on the Spark Plasma Sintering Diffusion Bonding of Diamond/Cu Composites with a Cr Interlayer. DOI: 10.3390/ma17246026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- What is the role of a laboratory oven in the pretreatment of raw materials? Optimize EBC Powder Flowability

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- What is the purpose of using a vacuum drying oven for coated carbon cloth? Protect Substrates & Optimize Adhesion

- What is the role of industrial thermometers in monitoring thermal stress? Ensure Safety via High-Precision Data

- What performance characteristics are required for a stainless steel tubular autoclave or reactor used in SCWG?

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- What is the importance of transferring freshly deposited CuO films directly into a 125°C oven? Ensure Film Adhesion

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation