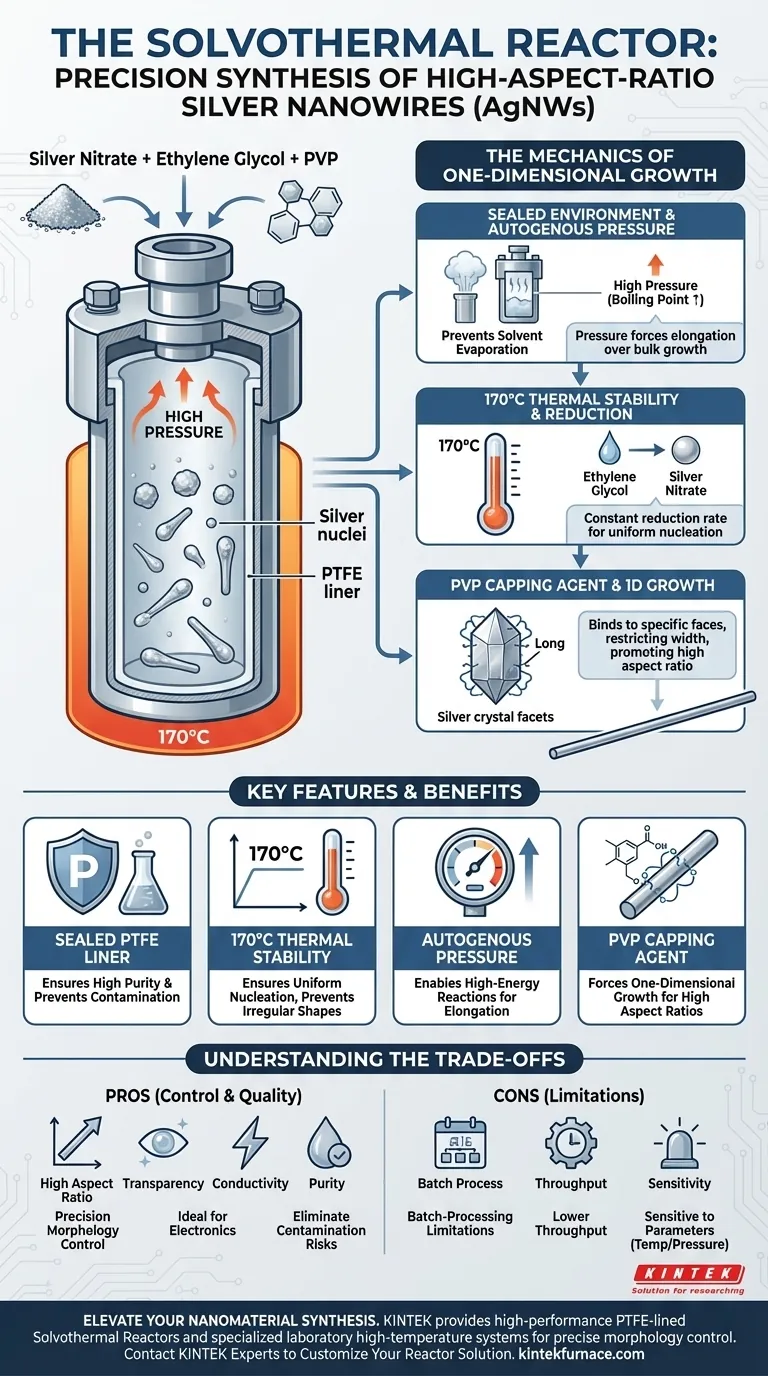

A solvothermal reactor acts as a precision growth chamber that dictates the physical geometry of silver nanostructures. By utilizing a PTFE-lined vessel to seal the reaction, the system allows ethylene glycol to reduce silver nitrate at a sustained 170°C. This creates a high-pressure environment that strictly controls the reaction kinetics, forcing silver nuclei to undergo one-dimensional growth rather than expanding spherically, ultimately yielding high-purity nanowires with high aspect ratios.

The reactor's sealed nature generates the internal pressure and thermal stability required to restrict crystal growth to a single axis, transforming potential silver particles into long, conductive nanowires.

The Mechanics of One-Dimensional Growth

To understand why a solvothermal reactor is superior for this application, one must look beyond the simple application of heat. The reactor creates a specific set of thermodynamic conditions that favor elongation over bulk growth.

The Role of the Sealed Environment

The defining feature of this process is the sealed, closed system. Unlike an open beaker reaction, a solvothermal reactor prevents solvents from evaporating.

This traps the vapors creates autogenous pressure (pressure generated by the solvent itself upon heating). This high pressure significantly increases the boiling point of the solvent, allowing the reaction to proceed at higher energy levels without losing the medium.

Thermal Stability and Reduction

Temperature control is the engine of the synthesis. The primary reference specifies a constant temperature of 170°C.

At this specific thermal plateau, ethylene glycol acts as a reducing agent for the silver nitrate. The stability provided by the reactor ensures the reduction rate is constant, which is critical for uniform nucleation. If the temperature fluctuates, the wires may break or form irregular shapes.

Chemical Stabilization via PVP

While the reactor provides the environment, the chemical mixture directs the shape. Polyvinylpyrrolidone (PVP) is introduced as a stabilizer.

In this high-pressure environment, PVP preferentially binds to specific faces of the growing silver crystal. This "capping" effect stops the crystal from growing wider and forces it to grow longer, resulting in the desired high aspect ratio.

The Function of the PTFE Liner

The reactor typically employs a polytetrafluoroethylene (PTFE) liner.

This creates a non-reactive barrier between the metal reactor walls and the chemical solution. It ensures high purity by preventing metallic impurities from the reactor vessel itself from leaching into the delicate silver solution.

Understanding the Trade-offs

While solvothermal synthesis provides exceptional control over morphology, it is important to recognize the inherent limitations of the process to determine if it fits your production scale.

Batch Process Limitations

Solvothermal reactors are inherently batch-processing tools.

Because the system must be sealed, heated, cooled, and opened, it is difficult to adapt this method for continuous, flow-based manufacturing. This limits the throughput compared to other industrial chemical processes.

Sensitivity to Parameters

The high-aspect-ratio relies on a delicate balance.

Slight deviations in the 170°C set point or leaks in the seal that reduce pressure can lead to the formation of silver nanoparticles (spheres) rather than nanowires. The process requires rigorous equipment calibration.

Making the Right Choice for Your Goal

When deciding on a synthesis method for silver nanomaterials, your specific end-goal dictates the necessity of a solvothermal reactor.

- If your primary focus is conductivity and transparency: Prioritize the solvothermal method, as the high aspect ratio ensures better percolation networks for transparent electrodes.

- If your primary focus is material purity: Rely on the PTFE-lined reactor configuration to eliminate contamination risks during the reduction process.

The solvothermal reactor remains the definitive tool for converting raw silver chemistry into the precise, elongated structures required for modern electronics.

Summary Table:

| Feature | Role in AgNW Synthesis | Benefit to Nanowire Quality |

|---|---|---|

| Sealed PTFE Liner | Prevents evaporation and contamination | Ensures high purity and autogenous pressure |

| 170°C Thermal Stability | Maintains constant reduction rate | Ensures uniform nucleation and prevents irregular shapes |

| Autogenous Pressure | Increases solvent boiling point | Enables high-energy reactions for elongation |

| PVP Capping Agent | Binds to specific crystal faces | Forces one-dimensional growth for high aspect ratios |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise morphology control in silver nanowire production demands equipment that offers uncompromising thermal stability and chemical purity. KINTEK provides high-performance PTFE-lined Solvothermal Reactors and specialized laboratory high-temperature systems designed to meet the rigorous kinetics of one-dimensional crystal growth.

Backed by expert R&D and manufacturing, our range—including Muffle, Tube, Rotary, Vacuum, and CVD systems—is fully customizable to your unique research or production needs. Ensure the highest aspect ratios and conductivity for your materials today.

Contact KINTEK Experts to Customize Your Reactor Solution

Visual Guide

References

- Bernadeta Ayu Widyaningrum, Heri Septya Kusuma. Chitosan-Reinforced Carbon Aerogels from Oil Palm Fronds for Enhanced Oil Absorption and Silver Nanowires Loaded as Antimicrobial Activity. DOI: 10.21203/rs.3.rs-7269305/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What roles does a laboratory oven play in biochar production? Enhance Efficiency and Accuracy in Thermal Processing

- What is the function of a high-temperature heating reactor in OPF delignification? Unlock High-Purity Cellulose

- What is the importance of controlling gas flow rates during purging? Prevent Thermal Stress and Equipment Failure

- What role does a high-power graphite resistance furnace play in SiC ceramic treatment? Achieve Perfect Crystallization

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- How do industrial furnaces and quenching tanks affect TiCp/Fe composites? Optimize Heat Treatment Performance

- Why is a vacuum desiccator used for the preservation of extracted fruit peel extracts? Protect Bioactive Compounds

- Why is it necessary to dry Industrial EAF slag before hydrogen reduction? Crucial Safety and Accuracy Prep