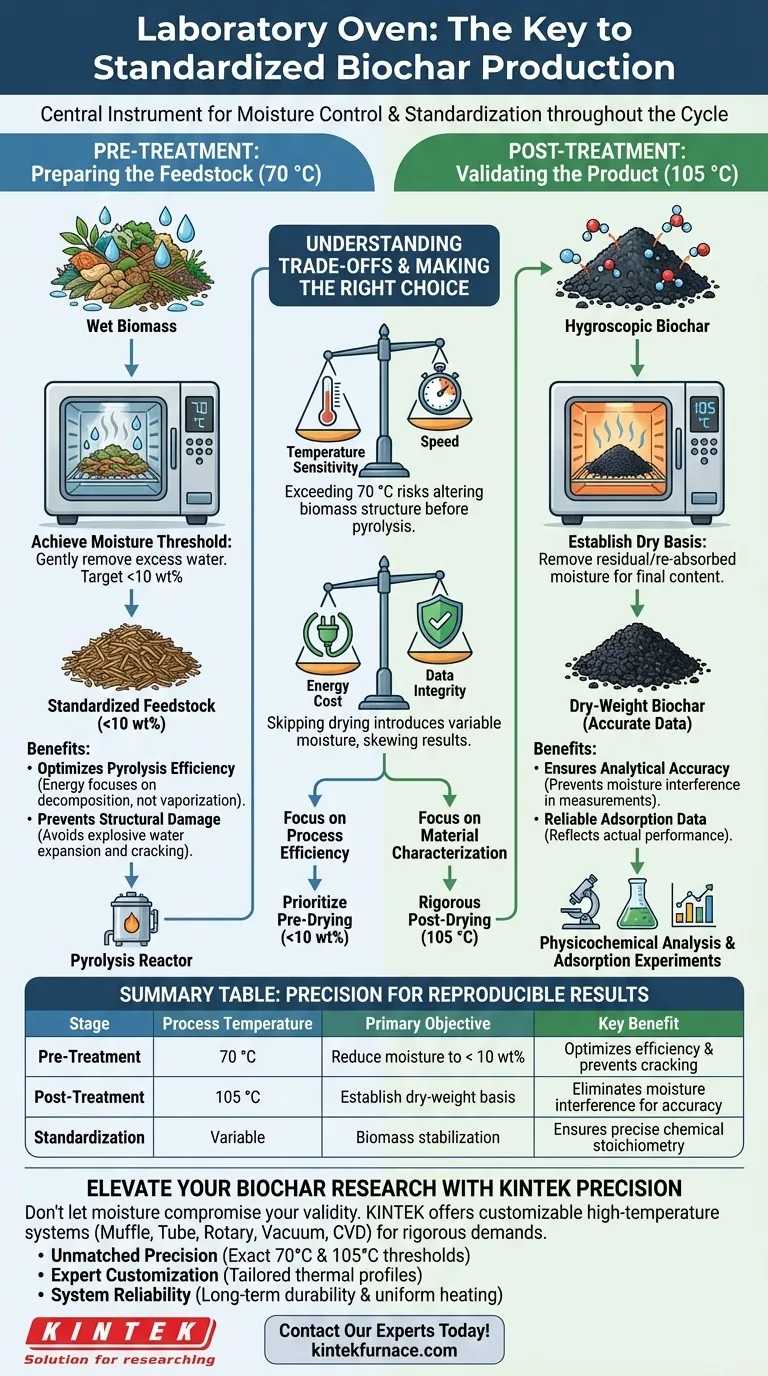

A laboratory oven acts as the central instrument for moisture control and standardization throughout the biochar production cycle. In the pre-treatment phase, it reduces biomass moisture (typically at 70 °C) to below 10 wt% to optimize pyrolysis efficiency, while in the post-treatment phase, it dries the finished biochar (at 105 °C) to eliminate moisture interference during physicochemical analysis and adsorption experiments.

The laboratory oven transforms variable biomass into a standardized feedstock and ensures that final biochar characterization is based on accurate, dry-weight data rather than fluctuating moisture content.

Pre-Treatment: Preparing the Feedstock

Achieving the Moisture Threshold

The primary role of the oven prior to pyrolysis is to stabilize the biomass. By heating the material at 70 °C, the oven gently removes excess water without triggering premature thermal degradation.

The target is to reduce the moisture content to below 10 wt%. This specific threshold is critical for establishing a consistent baseline before the material enters the reactor.

Improving Pyrolysis Efficiency

Wet biomass is inefficient to process. If the feedstock contains excess water, the pyrolysis reactor must expend significant energy vaporizing that water before carbonization can occur.

Pre-drying the material ensures that the energy applied during pyrolysis is directed immediately toward the thermal decomposition of the organic matter, rather than phase-changing water.

Preventing Structural Damage

Rapid vaporization of internal moisture during high-temperature pyrolysis can be destructive. If water remains in the pores, it expands explosively when heated.

By removing surface and physically adsorbed water in the oven first, you prevent material cracking. This preserves the structural integrity of the biochar and allows for better control over chemical stoichiometry.

Post-Treatment: Validating the Product

Establishing the Dry Basis

Once biochar is produced, it must be characterized. However, biochar is hygroscopic and can re-absorb moisture from the air.

The laboratory oven is used to heat the produced biochar to 105 °C. This removes any residual or re-absorbed moisture, allowing researchers to determine the material's true final moisture content.

Ensuring Analytical Accuracy

Moisture is a major contaminant in data collection. If biochar is not perfectly dry, water molecules will occupy pore sites and add mass.

This interference skews results in component analysis and adsorption experiments. Oven drying ensures that measurements of surface area, porosity, and contaminant removal capacity reflect the biochar's actual performance, not the water it holds.

Understanding the Trade-offs

Temperature Sensitivity vs. Speed

There is often a temptation to increase oven temperatures to speed up drying. However, exceeding recommended temperatures (like the 70 °C pre-treatment standard) risks altering the chemical structure of the biomass before pyrolysis begins.

Energy Cost vs. Data Integrity

Running laboratory ovens for extended periods consumes energy. However, skipping or shortening these drying cycles introduces a variable—moisture—that makes experimental data unreproducible. The energy cost of the oven is the price of scientific validity.

Making the Right Choice for Your Goal

To ensure your biochar production yields reliable data and high-quality material, apply the oven protocols based on your specific objective:

- If your primary focus is Process Efficiency: Prioritize pre-drying feedstock to <10 wt% to minimize energy waste and prevent physical cracking inside the reactor.

- If your primary focus is Material Characterization: rigorous post-drying at 105 °C is mandatory to ensure adsorption data and physicochemical indicators are not skewed by moisture weight.

Precision in thermal pre- and post-treatment is the defining factor between rough estimation and reproducible scientific results.

Summary Table:

| Stage | Process Temperature | Primary Objective | Key Benefit |

|---|---|---|---|

| Pre-Treatment | 70 °C | Reduce moisture to < 10 wt% | Optimizes pyrolysis efficiency & prevents structural cracking |

| Post-Treatment | 105 °C | Establish dry-weight basis | Eliminates moisture interference for accurate adsorption data |

| Standardization | Variable | Biomass stabilization | Ensures reproducible results and precise chemical stoichiometry |

Elevate Your Biochar Research with KINTEK Precision

Don't let moisture interference compromise your experimental validity. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of laboratory ovens and high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your biochar research and production.

Our value to you:

- Unmatched Precision: Achieve the exact moisture thresholds (70°C and 105°C) required for standardized feedstock and accurate characterization.

- Expert Customization: Tailor thermal profiles to your specific biomass types and research goals.

- System Reliability: Ensure long-term durability and uniform heating for reproducible scientific results.

Ready to optimize your thermal processing? Contact our experts today to find your perfect heating solution!

Visual Guide

References

- S. S. Ibrahim, Badr A. Mohamed. Catalyzed biochar from date palm waste for ammonium removal: potential application in poultry farms for ammonia mitigation. DOI: 10.1007/s43621-025-00817-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a high flow rate of synthetic air maintained during magnetite oxidation? Ensure Accurate Kinetic Modeling

- What reaction conditions are provided by stirring and heating equipment? Optimize Non-Aqueous Sol-Gel Synthesis

- What is the function of a laboratory cryofurnace during Co3O2BO3 experiments? Precise Phase Transition Control

- What chemical processes utilize electric furnaces? Achieve Unmatched Precision and Purity

- What is the impact of microwave power on the synthesis of 2D metal oxides? Master High-Speed Material Production

- What is the primary function of the low-temperature pyrolysis process? Ensure Safe Battery Recycling with Pretreatment

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety

- What is the purpose of preheating metal molds? Enhance Fluidity and Quality in Aluminum-Lithium Squeeze Casting