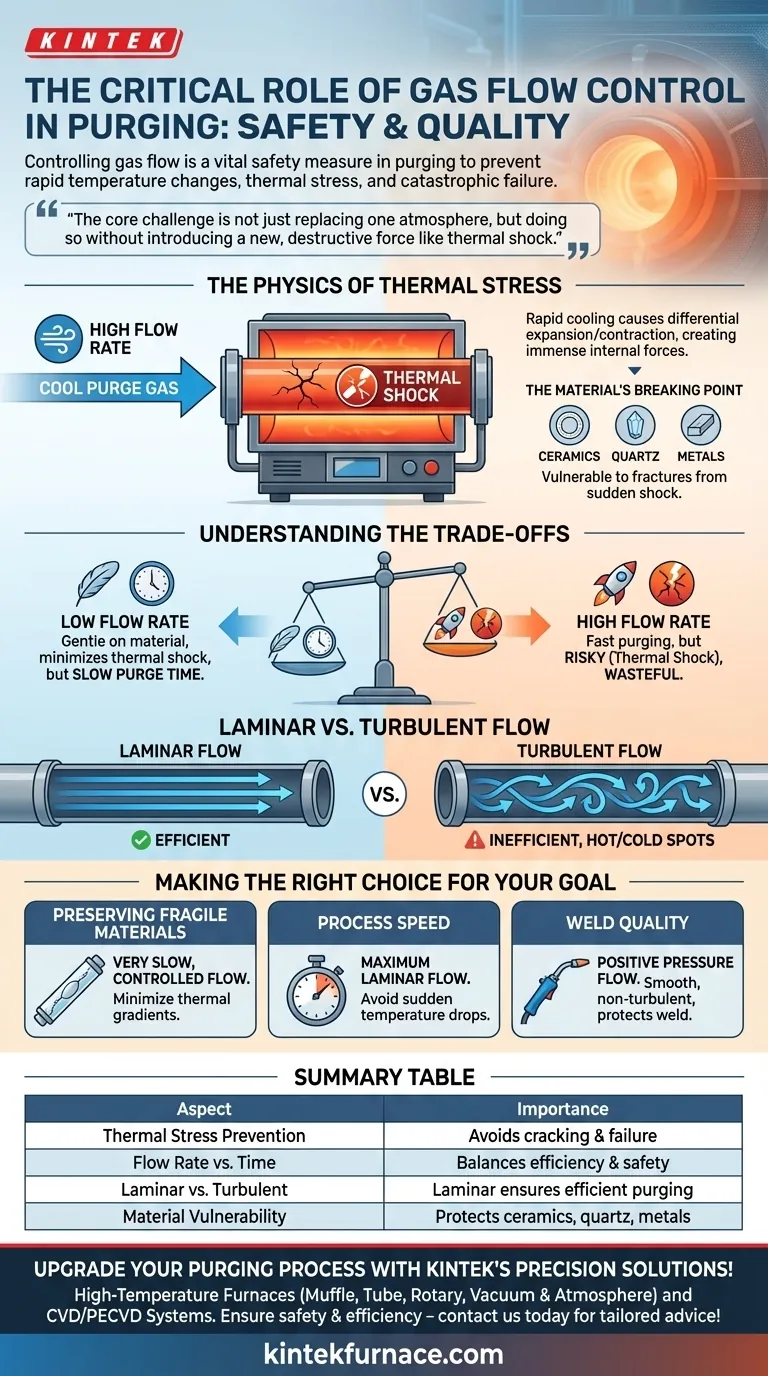

In any purging operation, controlling the gas flow rate is a critical safety and quality measure. The primary reason is to prevent large, rapid temperature differences within the material being purged, which can generate significant internal forces known as thermal stress and ultimately lead to cracking and catastrophic failure.

The core challenge of purging is not just replacing one atmosphere with another, but doing so without introducing a new, destructive force. Uncontrolled gas flow introduces thermal shock, which can compromise the structural integrity of your entire system.

The Physics of Thermal Stress

To understand why flow rate is so crucial, we must first understand the destructive potential of rapid temperature change.

What is Thermal Stress?

Materials expand when heated and contract when cooled. Thermal stress occurs when one part of an object tries to expand or contract at a different rate than another part.

This differential creates internal tension and compression forces. If these forces exceed the material's strength, it will crack or deform.

How Uncontrolled Flow Creates Stress

Purging often involves introducing a gas at ambient temperature into a system that is hot, such as a tube furnace or a freshly welded pipe.

A high, uncontrolled flow rate acts like a blast of cold air. It rapidly cools the interior surface of the tube while the bulk of the material remains hot.

This extreme temperature gradient—hot on the outside, cold on the inside—causes the inner surface to contract violently while the outer material resists, generating immense internal stress.

The Material's Breaking Point

Materials like ceramics, quartz, and certain metals are particularly vulnerable to thermal stress, especially when they are already at high temperatures. The sudden shock from a high flow of cool purge gas can easily be the breaking point, causing fractures that compromise the process and the equipment.

Understanding the Trade-offs

Properly managing purge gas flow is a balancing act between efficiency and safety. Ignoring the trade-offs can lead to failed processes or damaged equipment.

Flow Rate vs. Purge Time

A very low flow rate will be gentle on the material and minimize thermal shock, but it may take an impractically long time to fully displace the existing atmosphere.

Conversely, a high flow rate purges the volume quickly but dramatically increases the risk of thermal shock and cracking. It can also be wasteful, using more gas than necessary.

Laminar vs. Turbulent Flow

The ideal purge uses laminar flow, where gas moves in smooth, parallel layers. This efficiently and predictably displaces the unwanted atmosphere from the bottom up or one end to the other.

High flow rates create turbulent flow, where the gas swirls chaotically. Turbulence is not only inefficient at purging but can also create localized hot and cold spots, exacerbating thermal stress. For welding, turbulence can even pull atmospheric contaminants back into the inert environment.

Making the Right Choice for Your Goal

Your optimal flow rate depends entirely on your specific process and priorities.

- If your primary focus is preserving fragile materials (like quartz tubes): Use a very slow, controlled flow rate and allow for a longer purge time to minimize thermal gradients.

- If your primary focus is process speed: Determine the maximum flow rate that maintains laminar flow and does not cause a sudden, significant temperature drop in your system.

- If your primary focus is weld quality: Use a flow rate just high enough to provide positive pressure and displace oxygen, ensuring a smooth, non-turbulent flow that protects the weld pool without causing contamination or thermal shock.

Mastering your process begins with mastering control over every variable, especially gas flow.

Summary Table:

| Aspect | Importance |

|---|---|

| Thermal Stress Prevention | Avoids cracking and failure from rapid temperature changes |

| Flow Rate vs. Purge Time | Balances efficiency and safety; low flow is gentle but slow, high flow is fast but risky |

| Laminar vs. Turbulent Flow | Laminar flow ensures efficient, predictable purging; turbulent flow causes stress and inefficiency |

| Material Vulnerability | Protects ceramics, quartz, and metals from thermal shock during purging |

Upgrade your purging process with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique needs. Ensure safety and efficiency—contact us today for tailored advice!

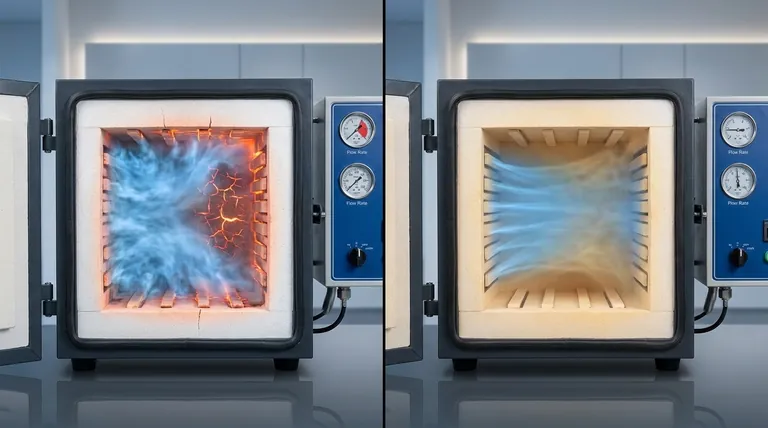

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control