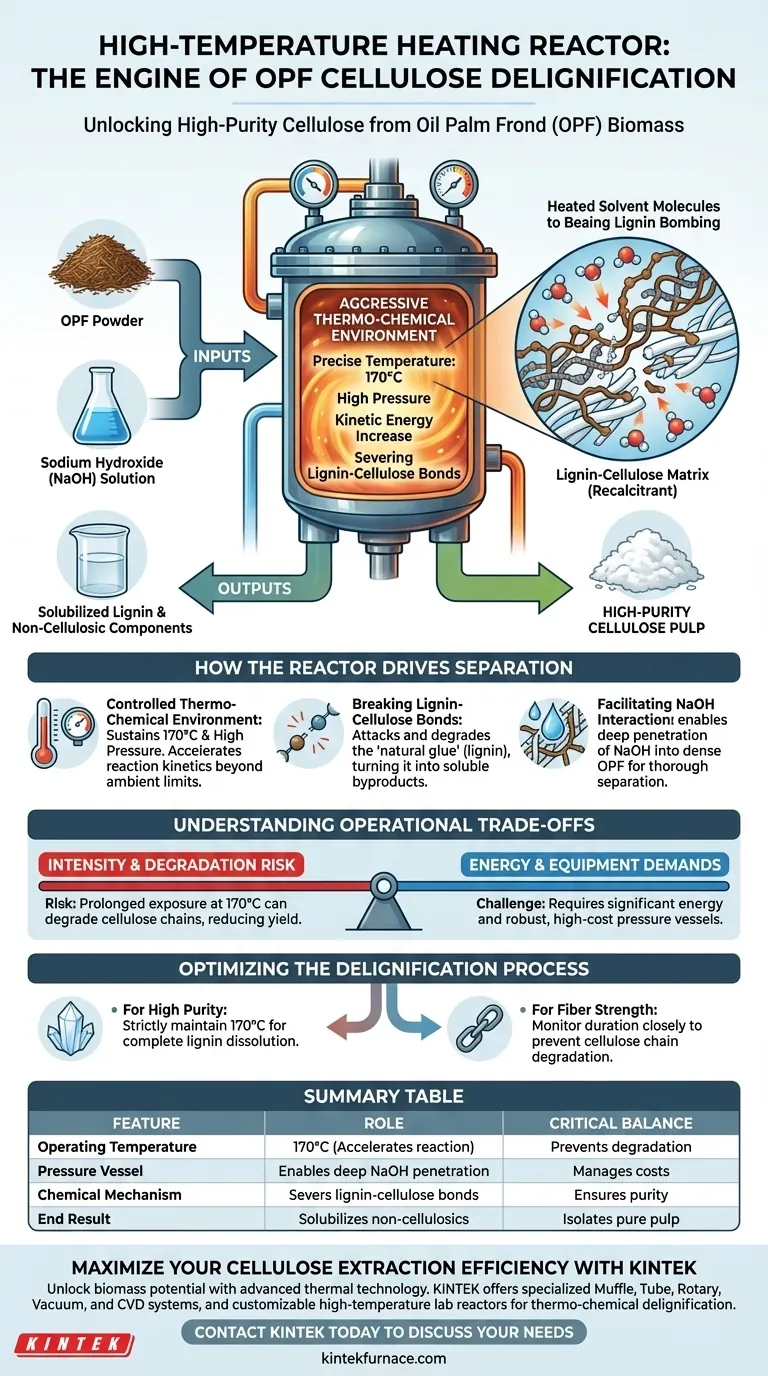

The primary function of a high-temperature heating reactor in this process is to facilitate a rigorous thermo-chemical reaction between Oil Palm Frond (OPF) powder and a sodium hydroxide solution. By maintaining a precise temperature of 170°C under high pressure, the reactor provides the necessary energy to sever the strong chemical bonds linking lignin to cellulose. This aggressive environment allows for the effective solubilization of non-cellulosic components, resulting in the isolation of high-purity cellulose pulp.

The reactor serves as the critical engine for overcoming biomass recalcitrance. By combining high heat and pressure, it forces the chemical breakdown of the protective lignin barrier, unlocking pure cellulose fibers that are otherwise inaccessible.

How the Reactor Drives Separation

To understand the reactor's role, we must look beyond simple heating. It acts as a pressurized vessel that enables the chemical solvent to penetrate the dense structure of the OPF biomass.

Creating a Controlled Thermo-Chemical Environment

The reactor is designed to reach and sustain a specific operating temperature of 170°C.

At this temperature, the kinetic energy of the molecules increases significantly. This accelerates the reaction rate between the biomass and the solvent far beyond what is possible at ambient temperatures.

Breaking the Lignin-Cellulose Bonds

Lignin acts as a natural glue, binding cellulose and hemicellulose together in a rigid structure.

The combination of high heat and pressure within the reactor attacks the chemical bonds holding this structure together. This "thermo-chemical action" effectively degrades the lignin and hemicellulose, turning them into soluble byproducts while leaving the cellulose intact.

Facilitating Sodium Hydroxide Interaction

The reactor creates the optimal conditions for the sodium hydroxide solution to do its work.

Under high pressure, the solution can penetrate deep into the OPF powder. The heat ensures that the sodium hydroxide reacts efficiently with the lignin, ensuring a thorough separation process rather than a superficial surface treatment.

Understanding the Operational Trade-offs

While the high-temperature reactor is essential for delignification, the process involves specific constraints that must be managed to ensure success.

Balancing Intensity and degradation

The aggressive environment of 170°C is necessary to remove lignin, but it presents a risk to the cellulose itself.

If the reaction conditions are uncontrolled or prolonged, the heat can begin to degrade the cellulose chains. This would reduce the yield and quality of the final pulp.

Energy and Equipment Demands

Maintaining high pressure and high temperature requires significant energy input.

Furthermore, the reactor vessel must be robust enough to withstand these conditions safely. This adds to the operational complexity and capital cost compared to low-temperature or atmospheric extraction methods.

Optimizing the Delignification Process

To achieve the best results with OPF cellulose extraction, you must align your operational parameters with your specific output goals.

- If your primary focus is high purity: Strictly maintain the 170°C temperature setpoint to ensure the complete dissolution of lignin and hemicellulose.

- If your primary focus is preserving fiber strength: Monitor the reaction duration closely to prevent the thermo-chemical action from degrading the cellulose chains after the lignin has been removed.

Mastering the reactor's environment is the single most important factor in converting raw agricultural waste into valuable industrial cellulose.

Summary Table:

| Feature | Role in Delignification Process |

|---|---|

| Operating Temperature | 170°C (Accelerates thermo-chemical reaction rate) |

| Pressure Vessel | Enables deep penetration of NaOH into dense OPF fibers |

| Chemical Mechanism | Severs bonds between lignin and cellulose fibers |

| End Result | Solubilizes non-cellulosic components for pure pulp isolation |

| Critical Balance | Prevents cellulose chain degradation while removing lignin |

Maximize Your Cellulose Extraction Efficiency

Unlock the full potential of your biomass research with KINTEK’s advanced thermal technology. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature lab reactors designed to handle the rigorous demands of thermo-chemical delignification.

Whether you are processing Oil Palm Frond or other complex biomass, our systems provide the precise temperature control and pressure stability needed to isolate high-purity cellulose while preserving fiber integrity.

Ready to optimize your lab's high-temperature processes? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Bernadeta Ayu Widyaningrum, Heri Septya Kusuma. Chitosan-Reinforced Carbon Aerogels from Oil Palm Fronds for Enhanced Oil Absorption and Silver Nanowires Loaded as Antimicrobial Activity. DOI: 10.21203/rs.3.rs-7269305/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are the effects of heat treatment furnace parameters on AlSi10Mg evaluated? Master Microstructural Analysis

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- Why is a mixture of Argon (Ar) and Hydrogen (H2) required during beryl heat treatment? Master Color Transformation

- What is the core role of a high-pressure autoclave in the synthesis of LTA zeolites? Achieve Precise Crystal Growth

- What is the significance of high vacuum base pressure in MoS2 sputtering? Ensuring Film Purity and Stoichiometry

- How does a vacuum pressure impregnation tank achieve deep treatment? Master Advanced Wood Modification Methods

- How do MFCs and Precursor Bottles Work in AP-ALD? Master Precision Vapor Draw for Atomic Coatings

- Why is precise control of carrier gas flow rates required for hydrochar activation? Optimize Carbon Yield & Purity