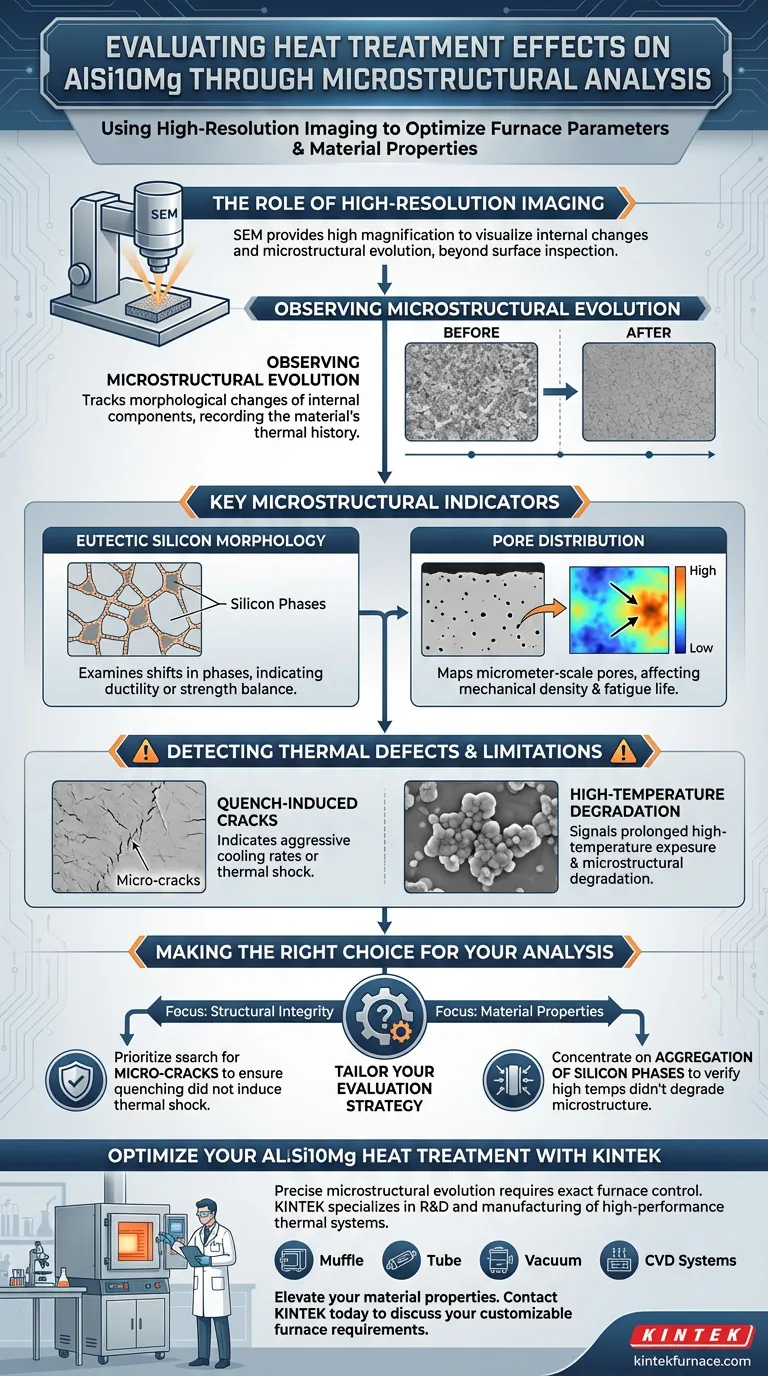

The evaluation of heat treatment effectiveness relies on high-resolution imaging techniques. Specifically, Scanning Electron Microscopy (SEM) is utilized to visualize the internal changes within AlSi10Mg. This method allows for a detailed assessment of how furnace parameters influence eutectic silicon morphology and the distribution of micrometer-scale pores.

Visual evidence determines process quality. Analyzing microstructural evolution is essential to confirm that heat treatment settings optimize material properties rather than inducing thermal shock or degradation.

The Role of High-Resolution Imaging

Leveraging Scanning Electron Microscopy (SEM)

To accurately gauge the impact of furnace parameters, engineers must look beyond surface-level inspection. SEM provides the high magnification necessary to observe the evolution of the material's microstructure. This level of detail is required to capture subtle changes that indicate whether the treatment was successful.

Observing Microstructural Evolution

The primary focus of this analysis is observing how the material changes over time under heat. By comparing images before and after treatment, analysts track the morphological changes of the alloy's internal components. This evolution serves as a direct record of the thermal history the part has experienced.

Key Microstructural Indicators

Monitoring Eutectic Silicon Morphology

One of the most critical indicators of heat treatment effects is the state of the silicon within the alloy. Analysts examine the eutectic silicon morphology to understand how the phases have shifted. Changes here can indicate whether the material has achieved the desired ductility or strength balance.

Analyzing Pore Distribution

Heat treatment can alter the internal void structure of the material. Evaluations must map the distribution of micrometer-scale pores throughout the sample. A shift in pore distribution can affect the mechanical density and fatigue life of the component.

Detecting Thermal Defects and Limitations

Identifying Quench-Induced Cracks

A critical trade-off in heat treatment is the risk of thermal shock during rapid cooling. Microstructural analysis specifically looks for micro-cracks caused by quenching. The presence of these cracks indicates that the cooling rate was too aggressive for the material's geometry.

Recognizing High-Temperature Degradation

Excessive heat exposure can be just as damaging as rapid cooling. Analysts look for the aggregation of silicon phases, which occurs due to prolonged high-temperature exposure. This aggregation acts as visual evidence of microstructural degradation, signaling that the furnace parameters may have exceeded the optimal thermal window.

Making the Right Choice for Your Analysis

To ensure the reliability of your AlSi10Mg components, you must tailor your evaluation strategy to the specific risks of your heat treatment cycle.

- If your primary focus is Structural Integrity: Prioritize the search for micro-cracks to ensure the quenching process did not induce thermal shock.

- If your primary focus is Material Properties: Concentrate on the aggregation of silicon phases to verify that high temperatures have not degraded the microstructure.

Ultimately, the goal is to use visual data to validate that furnace settings improve the material without compromising its internal architecture.

Summary Table:

| Evaluation Indicator | Analysis Technique | Impact of Furnace Parameters |

|---|---|---|

| Eutectic Silicon Morphology | SEM Imaging | Determines material ductility and strength balance |

| Pore Distribution | Micrometer-scale Mapping | Affects mechanical density and component fatigue life |

| Quench-Induced Cracks | High-Resolution Inspection | Indicates excessive cooling rates or thermal shock |

| Phase Aggregation | Microstructural Comparison | Signals degradation due to prolonged high-temperature exposure |

Optimize Your AlSi10Mg Heat Treatment with KINTEK

Precise microstructural evolution requires exact furnace control. At KINTEK, we specialize in the R&D and manufacturing of high-performance thermal systems designed for the rigorous demands of advanced metallurgy.

Whether you need Muffle, Tube, Vacuum, or CVD systems, our laboratory high-temperature furnaces provide the thermal stability necessary to prevent phase aggregation and quenching defects.

Ready to elevate your material properties? Contact KINTEK today to discuss your customizable furnace requirements.

Visual Guide

References

- Busisiwe J. Mfusi, Ntombi Mathe. Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. DOI: 10.3390/met14030292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do elliptical mirrors function to create a horizontal temperature field in an optical Floating-Zone furnace?

- What role does a vacuum oven play in the post-treatment of nano-hydroxyapatite coatings? Ensure Crack-Free Integrity

- Why is aluminum foil used during selenization and carbonization? Unlock Superior ZnSe Nanoparticle Synthesis

- Why is a high-precision constant temperature drying oven required for biochar? Protect Delicate Pore Structures

- What is the significance of rapid quenching equipment in verifying the reaction pathway of BiFeO3? Capturing Intermediate Phases

- Why is the drying step using an industrial electric oven critical in catalyst preparation? Ensure Structural Integrity

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- What is the operating principle of a vacuum freeze-dryer in the fabrication of carbon aerogels? Master Sublimation