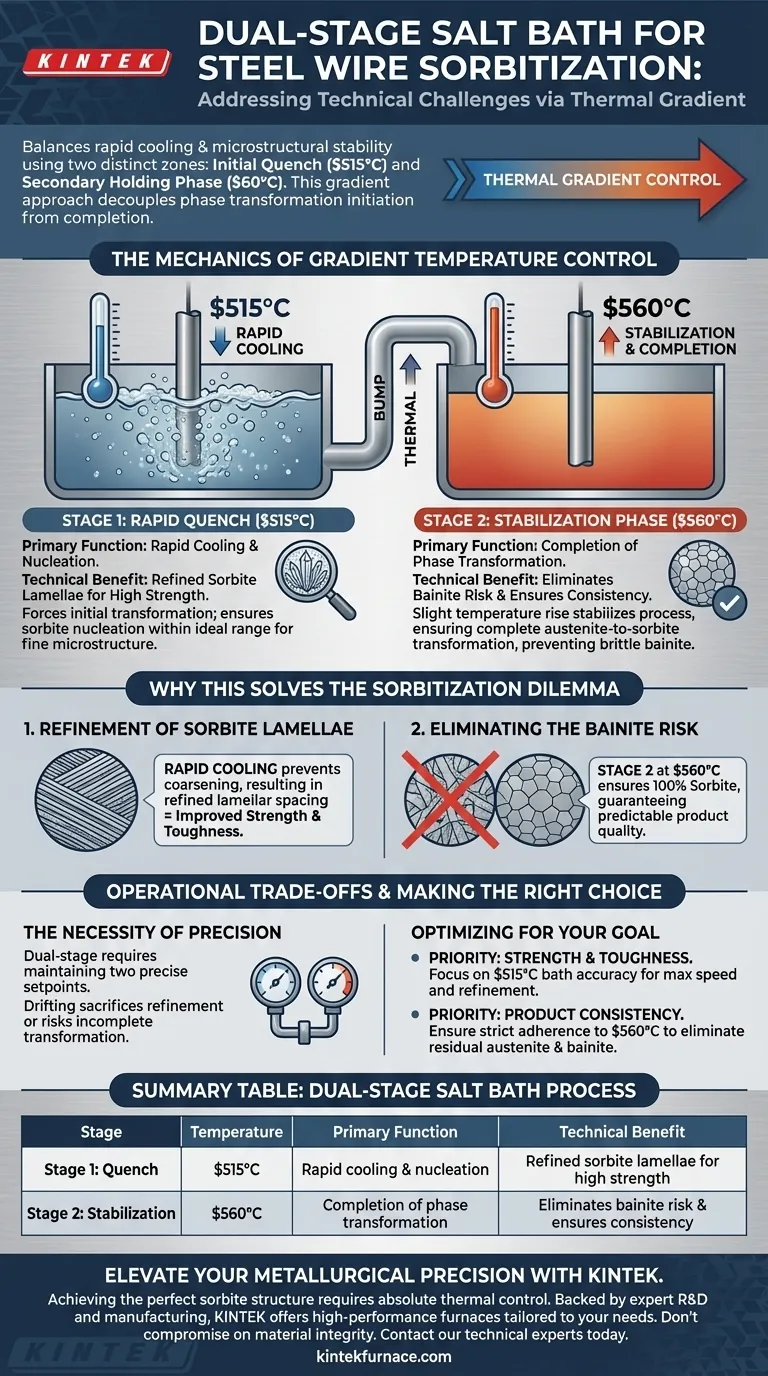

The dual-stage salt bath design addresses the conflicting requirements of rapid cooling and microstructural stability by utilizing two distinct temperature zones: an initial quench at $515^\circ\text{C}$ and a secondary holding phase at $560^\circ\text{C}$.

This gradient approach decouples the initiation of the phase transformation from its completion. The first stage drives rapid cooling to refine the microstructure, while the second stage ensures the steel fully transforms into sorbite rather than undesirable phases.

By managing the thermal profile in steps, this system resolves the trade-off between cooling speed and phase purity, preventing the formation of brittle bainite while maximizing the strength and toughness of the steel wire.

The Mechanics of Gradient Temperature Control

Stage 1: The Rapid Quench ($515^\circ\text{C}$)

The primary challenge in sorbitization is achieving a fine microstructure without inducing defects.

The first bath is set to $515^\circ\text{C}$ to create a high temperature differential between the hot wire and the cooling medium.

This "thermal shock" forces the initial phase transformation to occur rapidly. By keeping the temperature lower during this phase, the system ensures the nucleation of sorbite happens within the ideal range, setting the foundation for high strength.

Stage 2: The Stabilization Phase ($560^\circ\text{C}$)

The secondary challenge is handling the "tail end" of the transformation process.

If the wire remains at the lower $515^\circ\text{C}$ temperature for too long, or cools further, there is a risk that the remaining austenite will transform into bainite.

The second bath at $560^\circ\text{C}$ raises the temperature slightly to stabilize the process. This thermal bump ensures that any residual austenite transforms completely into sorbite, securing the integrity of the material.

Why This Solves the Sorbitization Dilemma

Refinement of Sorbite Lamellae

Strength in steel wire is largely dictated by the fineness of its internal structure, specifically the sorbite lamellae.

The rapid cooling in the first stage prevents the crystal structure from growing too large (coarsening).

This results in a refined lamellar spacing, which directly translates to improved mechanical properties, specifically higher strength and toughness.

Eliminating the Bainite Risk

Bainite is a lower-performance microstructure that creates inconsistency in steel wire products.

The dual-stage design specifically targets the elimination of bainite by moving the process to $560^\circ\text{C}$ before bainite can form.

This guarantees that the final product is composed entirely of sorbite, ensuring stable and predictable quality across the entire production run.

Understanding the Operational Trade-offs

The Necessity of Precision

While a single-stage bath is simpler to operate, it lacks the flexibility to optimize both nucleation and growth simultaneously.

The dual-stage system introduces complexity, as it requires maintaining two precise temperature setpoints ($515^\circ\text{C}$ and $560^\circ\text{C}$).

Drifting from the $515^\circ\text{C}$ setpoint in the first stage sacrifices structure refinement, while failing to maintain $560^\circ\text{C}$ in the second stage risks incomplete transformation.

Making the Right Choice for Your Goal

To maximize the benefits of this dual-stage design, focus on the specific role of each bath:

- If your primary focus is Strength and Toughness: Prioritize the accuracy of the $515^\circ\text{C}$ bath to maximize the speed of the initial quench and lamellar refinement.

- If your primary focus is Product Consistency: Ensure strict adherence to the $560^\circ\text{C}$ setpoint in the second stage to eliminate residual austenite and prevent bainite formation.

The dual-stage salt bath is not just a cooling method; it is a precision tool for locking in the exact mechanical properties required for high-performance steel wire.

Summary Table:

| Stage | Temperature | Primary Function | Technical Benefit |

|---|---|---|---|

| Stage 1: Quench | 515°C | Rapid cooling & nucleation | Refined sorbite lamellae for high strength |

| Stage 2: Stabilization | 560°C | Completion of phase transformation | Eliminates bainite risk & ensures consistency |

Elevate Your Metallurgical Precision with KINTEK

Achieving the perfect sorbite structure requires absolute thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique steel treatment needs.

Don't compromise on material integrity. Our advanced heating solutions provide the stability and accuracy necessary to eliminate bainite and maximize toughness in your production line.

Ready to optimize your heat treatment process? Contact our technical experts today to find the perfect furnace for your laboratory or industrial application.

Visual Guide

References

- Jun Li, Jieyu Zhang. A Novel Design of a Molten Salt Bath Structure and Its Quenching Effect on Wire Transformation from Austenite to Sorbite. DOI: 10.3390/met14040483

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- What happens during the sintering process? Transform Powder into Dense, High-Strength Components

- What is the function of a gas-phase catalytic reaction system? Evaluate Carbon-Metal Nanocomposites with Precision

- Why is vacuum degassing necessary for ZIF-8 impregnation? Achieve Uniform Macroporous Material Synthesis

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation

- Why is high-purity argon gas used to purge the furnace? Ensure Precision in TGA Oxidation Kinetic Tests

- How can I improve my vacuum pump performance? Optimize Your System for Deeper Vacuum & Faster Pump-Down

- What are the advantages of PVD coating? Achieve Precision, Purity, and Eco-Friendly Performance