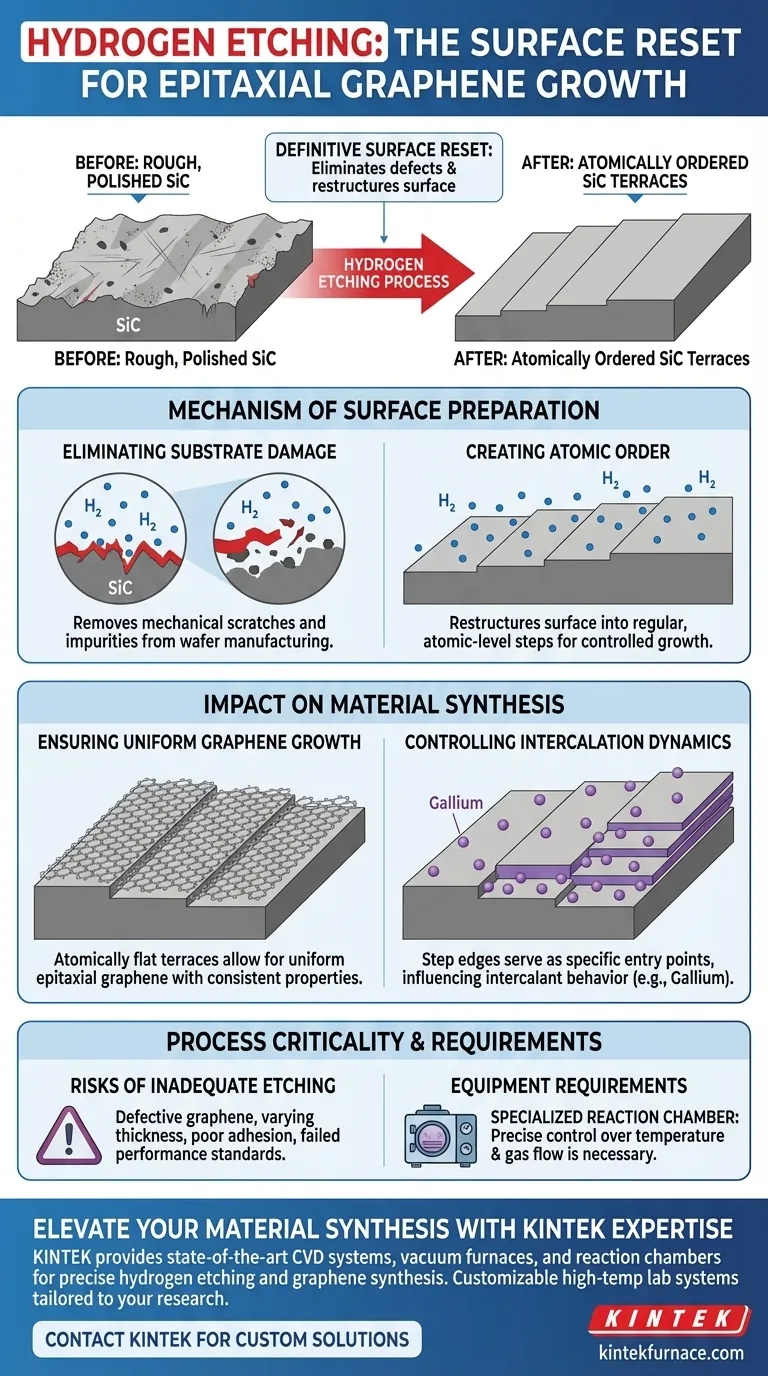

The significance of hydrogen etching lies in its ability to act as a definitive surface reset for Silicon Carbide (SiC) substrates prior to growth. This pre-treatment eliminates physical defects such as scratches and impurities while simultaneously restructuring the surface into regular, atomic-level steps to ensure high-quality material synthesis.

Core Takeaway Achieving a pristine starting surface is the single most critical factor for successful epitaxy. Hydrogen etching transforms a rough, polished substrate into an atomically ordered landscape, which is a prerequisite for growing uniform graphene and controlling the behavior of intercalated atoms like gallium.

The Mechanism of Surface Preparation

Eliminating Substrate Damage

Raw Silicon Carbide (SiC) substrates often arrive with microscopic imperfections.

Mechanical polishing processes used during wafer manufacturing leave behind surface scratches and impurities. Hydrogen etching in a reaction chamber effectively removes these layers, stripping away the damaged material to reveal the pristine crystal underneath.

Creating Atomic Order

Beyond simple cleaning, this process fundamentally restructures the surface morphology.

The etching creates regular, atomic-level steps across the substrate. This transition from a random, rough surface to an ordered, terraced structure is the physical foundation required for controlled epitaxial growth.

Impact on Material Synthesis

Ensuring Uniform Graphene Growth

The quality of epitaxial graphene is directly dependent on the quality of the underlying SiC surface.

Without the regular step structure provided by hydrogen etching, graphene growth would be disjointed and irregular. The atomically flat terraces allow the carbon atoms to arrange themselves into a uniform epitaxial graphene layer with consistent electronic properties.

Controlling Intercalation Dynamics

For advanced applications involving the insertion of other elements between layers, the surface structure is a control mechanism.

The primary reference notes that this process directly influences the intercalation dynamics of gallium atoms. The step edges created during etching serve as specific entry points or pathways, allowing for precise control over how foreign atoms interact with the graphene-substrate interface.

Understanding the Process Criticality

The Risks of Inadequate Etching

Skipping or shortening this pre-treatment step is a common point of failure.

If the surface retains scratches or lacks defined atomic steps, the subsequent graphene layer will likely suffer from defects, varying thickness, or poor adhesion. The result is a material that fails to meet electronic performance standards.

Equipment Requirements

This process cannot be performed loosely; it requires a specialized reaction chamber.

Precise control over temperature and gas flow is necessary to etch the SiC without degrading the crystal quality. This highlights that hydrogen etching is not merely a cleaning wipe, but a sophisticated thermodynamic process.

Making the Right Choice for Your Goal

When planning your epitaxial growth recipe, consider how hydrogen etching aligns with your specific targets:

- If your primary focus is Material Uniformity: Ensure the etching duration is sufficient to fully remove polishing damage and establish clear atomic terraces.

- If your primary focus is Intercalation (e.g., Gallium): Optimize the step morphology during etching, as the step edges will define how effectively the intercalant penetrates the interface.

Mastering the hydrogen etching phase is the non-negotiable first step toward achieving reproducible, high-performance epitaxial graphene devices.

Summary Table:

| Feature | Impact of Hydrogen Etching |

|---|---|

| Substrate Surface | Removes mechanical scratches, impurities, and polished damage. |

| Morphology | Restructures the surface into regular, atomic-level terraces. |

| Graphene Quality | Ensures uniform layer growth and consistent electronic properties. |

| Intercalation | Defines pathways for foreign atoms like Gallium to enter the interface. |

| Process Role | Acts as a definitive 'surface reset' for SiC substrates. |

Elevate Your Material Synthesis with KINTEK Expertise

Achieving the perfect atomic landscape for epitaxial growth requires precision-engineered equipment. KINTEK provides state-of-the-art CVD systems, vacuum furnaces, and specialized reaction chambers designed to handle the rigorous demands of hydrogen etching and graphene synthesis.

Our solutions are backed by expert R&D and manufacturing, offering fully customizable high-temp lab systems tailored to your unique research needs. Whether you are focused on material uniformity or complex intercalation dynamics, KINTEK ensures your laboratory is equipped for success.

Ready to optimize your epitaxial growth process? Contact KINTEK today to discuss your custom solution.

Visual Guide

References

- Emanuele Pompei, Stefano Veronesi. Novel Structures of Gallenene Intercalated in Epitaxial Graphene. DOI: 10.1002/smll.202505640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why Use a Vacuum Oven for Cu-Cu2O/g-C3N4 Catalysts? Preserve Purity and Structural Integrity

- Why is a high-purity argon flow control system essential? Ensure Precision in Metallurgy Simulations

- How does a solvothermal reactor contribute to silver nanowires synthesis? Precision Growth for High-Aspect-Ratio AgNWs

- What are the limitations of PVD coating? Overcome Challenges for Optimal Surface Engineering

- How does a sputtering system contribute to the preparation of electrodes? Enhance Bismuth Telluride Characterization

- How does a high vacuum deposition system ensure thin film quality? Purity Through Advanced Pumping

- What critical environment does a high-temp furnace provide for H13 steel? Mastering Microstructural Homogenization

- What is the function of a laboratory hot air drying oven in TiO2 treatment? Ensure Uniform Nanoparticle Quality