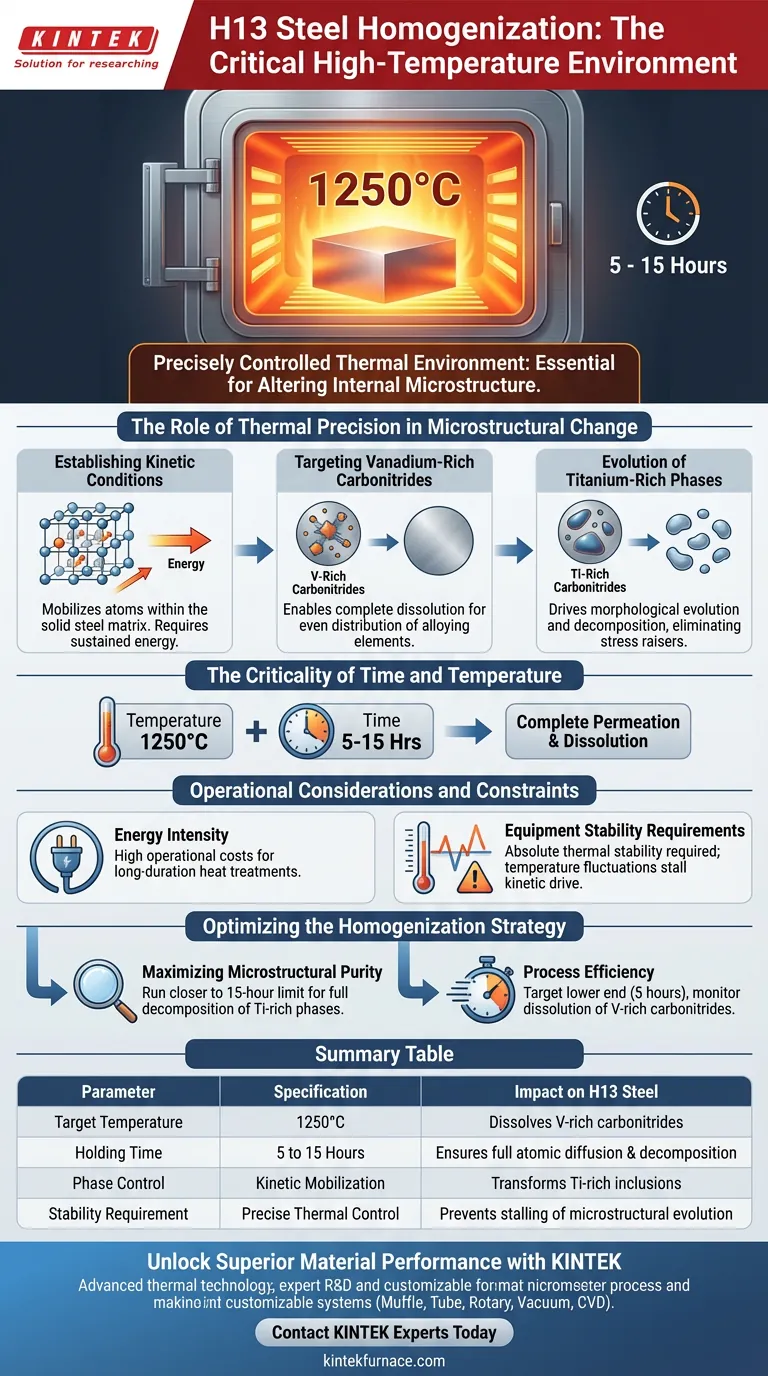

A high-temperature resistance furnace establishes a precisely controlled thermal environment. It creates a constant temperature setting, specifically around 1250°C, which is maintained for extended durations of 5 to 15 hours. This stability provides the essential kinetic conditions required to alter the internal microstructure of H13 steel.

The furnace acts as a catalyst for microstructural change by maintaining a high-energy, stable environment. This specific thermal exposure is critical to dissolving unstable carbonitrides and refining the steel’s composition for optimal performance.

The Role of Thermal Precision in Microstructural Change

To understand why this environment is critical, one must look beyond simple heating. The furnace provides the specific energy state required to manipulate the complex chemistry of H13 steel.

Establishing Kinetic Conditions

Homogenization is a diffusion-controlled process that does not happen instantaneously.

The furnace provides the necessary kinetic conditions to mobilize atoms within the solid steel matrix. Without this sustained energy input, the chemical changes required for homogenization would simply not occur.

Targeting Vanadium-Rich Carbonitrides

H13 steel often contains unstable phases that can compromise its mechanical properties.

The constant high-temperature environment enables the complete dissolution of vanadium-rich carbonitrides. By dissolving these precipitates, the furnace ensures the alloying elements are evenly distributed throughout the steel matrix.

Evolution of Titanium-Rich Phases

Titanium-rich inclusions are notoriously difficult to manage in steel processing.

The furnace's environment drives the morphological evolution and decomposition of these titanium-rich carbonitrides. This transformation is essential for eliminating stress raisers and improving the overall quality of the material.

The Criticality of Time and Temperature

Temperature alone is insufficient; the duration of exposure is equally vital.

The furnace maintains the 1250°C setpoint for 5 to 15 hours. This extended window ensures that the dissolution and decomposition processes have sufficient time to permeate the entire cross-section of the steel.

Operational Considerations and Constraints

While the high-temperature resistance furnace is essential for this process, there are inherent trade-offs that must be managed.

Energy Intensity

Maintaining 1250°C for up to 15 hours requires significant energy input.

Operators must balance the need for complete homogenization against the high operational costs associated with such long-duration heat treatments.

Equipment Stability Requirements

The process demands absolute thermal stability.

If the furnace fluctuates significantly below the target temperature, the kinetic drive may stall. This could result in incomplete dissolution of the carbonitrides, rendering the treatment ineffective.

Optimizing the Homogenization Strategy

Achieving the best results with H13 steel requires tailoring the furnace parameters to your specific material requirements.

- If your primary focus is maximizing microstructural purity: Ensure the process runs closer to the 15-hour upper limit to guarantee the full decomposition of stubborn titanium-rich phases.

- If your primary focus is process efficiency: Target the lower end of the time spectrum (5 hours) while strictly monitoring the complete dissolution of the more unstable vanadium-rich carbonitrides.

Precise thermal control is the non-negotiable key to unlocking the full structural potential of H13 steel.

Summary Table:

| Parameter | Specification | Impact on H13 Steel |

|---|---|---|

| Target Temperature | 1250°C | Dissolves vanadium-rich carbonitrides |

| Holding Time | 5 to 15 Hours | Ensures full atomic diffusion & decomposition |

| Phase Control | Kinetic Mobilization | Transforms titanium-rich inclusions |

| Stability Requirement | Precise Thermal Control | Prevents stalling of microstructural evolution |

Unlock Superior Material Performance with KINTEK

Precision is the non-negotiable factor in H13 steel homogenization. KINTEK provides the advanced thermal technology required to achieve perfect microstructural purity. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific lab or industrial high-temperature needs.

Our furnaces ensure the absolute stability required for long-duration heat treatments, helping you reduce energy waste while maximizing material quality. Ready to optimize your heat treatment process?

Visual Guide

References

- Xiaolin Sun, Shuo Zhao. Effects of Ti and N Contents on the Characteristic Evolution and Thermal Stability of MC Carbonitrides Holding at 1250 °C in H13 Die Steel. DOI: 10.3390/met14030317

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does controlled thermal treatment affect delta-MnO2? Optimize Porosity & Surface Area for Better Battery Performance

- What role does a high-performance blast drying oven play in the hydrothermal reaction stage of CoO/CoSe nanoparticles?

- What are the technical advantages of vacuum drying ovens for CeO2 separators? Protect Nanostructures & Boost Stability

- Why is Barium Titanate annealed after SPS? Restore Material Stoichiometry and Electrical Performance

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance

- How do Digital Twin and machine learning improve maintenance? Master High-Temp Equipment Reliability & Efficiency

- What role does a laboratory vacuum drying oven play in the post-treatment process of porous carbon derived from polyethylene terephthalate (PET)? Crucial for preserving material structure.

- What is zirconium dioxide and how is it stabilized for dental use? Discover the Science Behind Durable Dental Ceramics