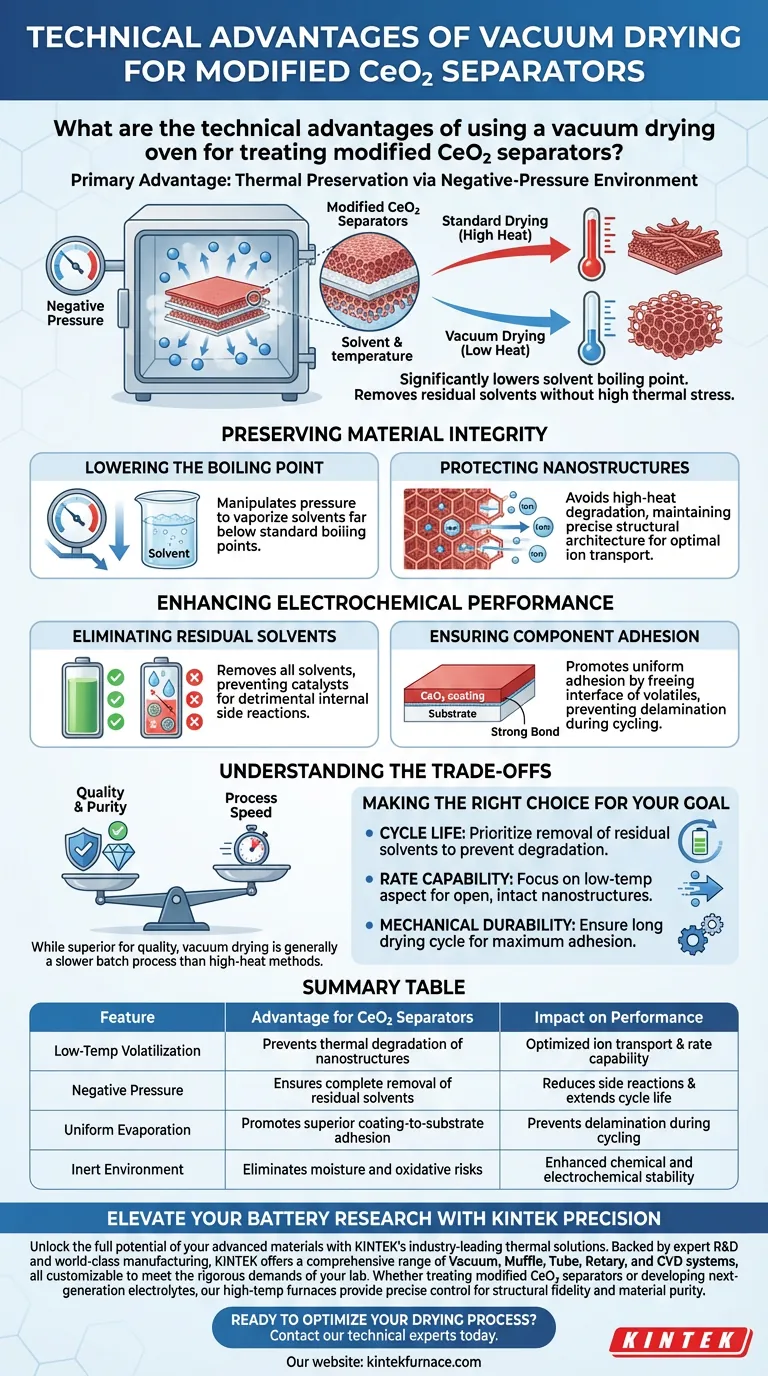

The primary technical advantage is thermal preservation. A vacuum drying oven utilizes a negative-pressure environment to significantly lower the boiling point of solvents, allowing for their complete removal at reduced temperatures. This process is essential for treating modified CeO2 separators because it eliminates residual solvents without subjecting the material to high heat that could degrade its delicate nanostructure.

By decoupling solvent evaporation from high thermal stress, vacuum drying ensures the structural integrity of CeO2 coatings while eliminating the moisture responsible for detrimental electrochemical side reactions.

Preserving Material Integrity

Lowering the Boiling Point

The fundamental mechanism of a vacuum drying oven is the manipulation of pressure. By creating a negative-pressure environment, the system allows solvents to vaporize at temperatures far below their standard boiling points.

Protecting Nanostructures

Modified CeO2 separators often rely on specific nanostructures to function effectively. High-temperature drying methods risk collapsing or altering these microscopic features.

Vacuum drying mitigates this risk entirely. It ensures the separator is dried thoroughly while maintaining the precise structural architecture required for optimal ion transport.

Enhancing Electrochemical Performance

Eliminating Residual Solvents

Any solvent left within the separator can be catastrophic once the battery is assembled. Residual moisture or chemicals often act as catalysts for internal side reactions.

These reactions can degrade the electrolyte or the electrode materials over time. Vacuum drying provides the most efficient method for removing these residues completely, stabilizing the internal chemistry of the cell.

Ensuring Component Adhesion

Mechanical stability is just as critical as chemical stability. The vacuum drying process promotes a stronger bond between the CeO2 coating and the separator substrate.

By ensuring the interface is completely free of volatiles, the coating adheres more uniformly. This prevents delamination during the charge-discharge cycles, which is a common failure point in coated separators.

Understanding the Trade-offs

Process Speed vs. Quality

While vacuum drying is superior for quality, it is generally a batch process that may be slower than continuous, high-heat drying methods.

Equipment Complexity

Maintaining a consistent negative-pressure environment requires more complex hardware than standard convection ovens. You must ensure the vacuum seals and pumps are regularly maintained to prevent pressure leaks that could compromise the drying consistency.

Making the Right Choice for Your Goal

To maximize the benefits of vacuum drying for your specific application, consider the following:

- If your primary focus is Cycle Life: Prioritize the removal of residual solvents to prevent the internal side reactions that degrade battery longevity.

- If your primary focus is Rate Capability: Focus on the low-temperature aspect to ensure the CeO2 nanostructures remain open and intact for efficient ion flow.

- If your primary focus is Mechanical Durability: Ensure the drying cycle is long enough to maximize adhesion between the coating and the substrate.

Vacuum drying is the definitive choice when material purity and structural fidelity outweigh the need for rapid, high-heat processing.

Summary Table:

| Feature | Advantage for CeO2 Separators | Impact on Performance |

|---|---|---|

| Low-Temp Volatilization | Prevents thermal degradation of nanostructures | Optimized ion transport & rate capability |

| Negative Pressure | Ensures complete removal of residual solvents | Reduces side reactions & extends cycle life |

| Uniform Evaporation | Promotes superior coating-to-substrate adhesion | Prevents delamination during cycling |

| Inert Environment | Eliminates moisture and oxidative risks | Enhanced chemical and electrochemical stability |

Elevate Your Battery Research with KINTEK Precision

Unlock the full potential of your advanced materials with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, Rotary, and CVD systems, all customizable to meet the rigorous demands of your lab. Whether you are treating modified CeO2 separators or developing next-generation electrolytes, our high-temp furnaces provide the precise control necessary for structural fidelity and material purity.

Ready to optimize your drying process? Contact our technical experts today to find the perfect customizable furnace for your unique research needs.

Visual Guide

References

- Hao Xiao, Dan Sun. MOF-Derived CeO2 Nanorod as a Separator Coating Enabling Enhanced Performance for Lithium–Sulfur Batteries. DOI: 10.3390/molecules29081852

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What unique advantages does microwave heating equipment provide for iron-containing dust reduction? Boost Recovery Rates

- Why must Sm:YAG ceramics undergo air annealing? Restoring Optical Clarity and Restructuring Defects

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- Why is a reaction vessel with pressure control necessary for Ru nanoparticle synthesis? Achieve Precision Morphology

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- What are the characteristics of a Batch Reactor for plastic pyrolysis? A Guide to Versatile Waste Processing

- What is the purpose of using an Argon protective atmosphere during the casting of H13 steel? Boost Purity and Strength

- Why is precise sample loading critical in CO2 capture experiments? Avoid Bed Effects and Ensure Data Integrity