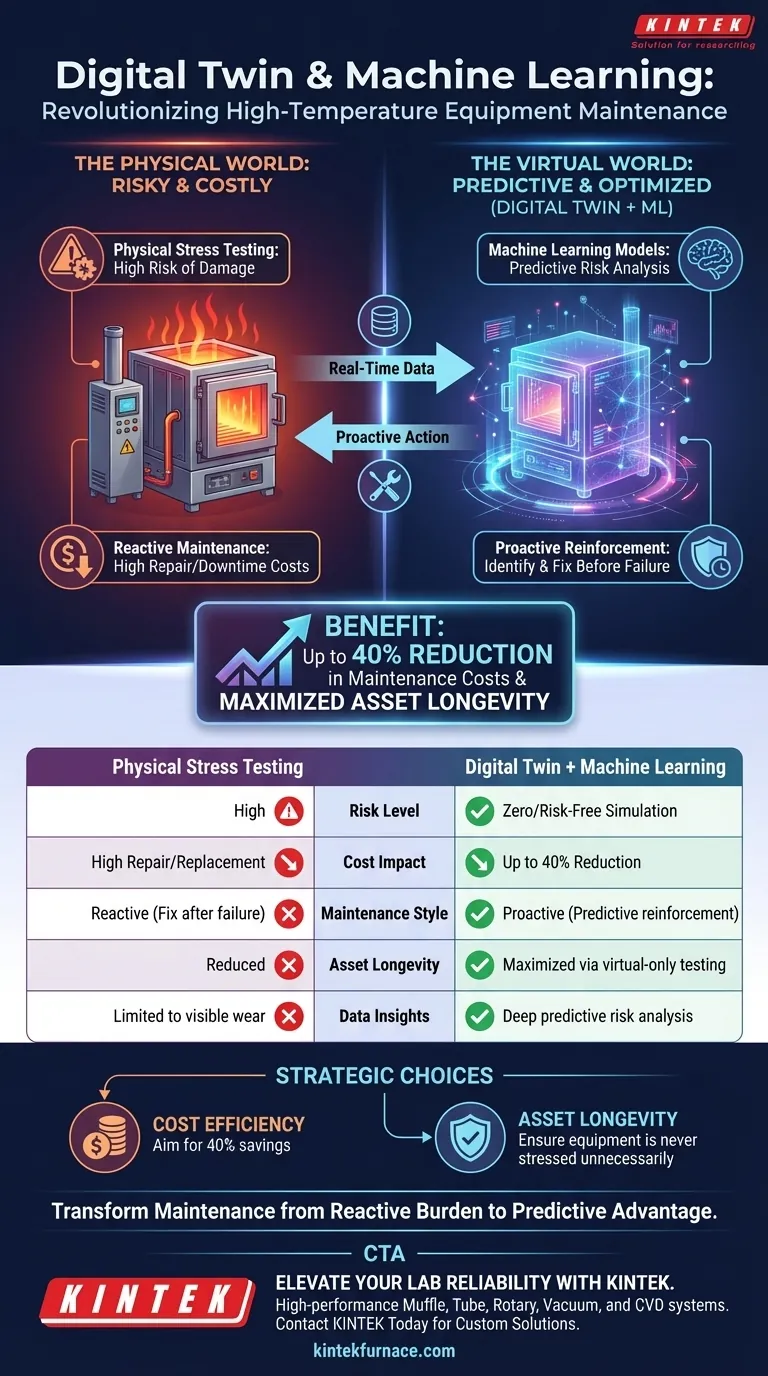

Digital Twin technology revolutionizes maintenance strategies by constructing a virtual mirror of complex assets to safely simulate extreme operational scenarios. When paired with machine learning, this system predicts failure points and enables teams to reinforce vulnerable components proactively, ensuring reliability without subjecting the physical equipment to dangerous stress tests.

By shifting stress testing from the physical world to a high-fidelity virtual environment, organizations can identify risks early and reduce overall maintenance costs by up to 40%.

The Mechanics of Virtual Simulation

Creating a Risk-Free Testing Environment

The primary challenge with high-temperature equipment, such as industrial furnaces, is the danger associated with stress testing. Digital Twin technology solves this by creating a virtual replica of the physical asset.

Simulating Extreme Scenarios

This digital environment allows engineers to run simulations of various extreme operating conditions. Because the testing happens virtually, the system can undergo rigorous stress tests without the risk of damaging the actual physical hardware.

The Role of Machine Learning

Predictive Risk Analysis

Within the virtual replica, machine learning models analyze performance data to perform risk predictions. These algorithms identify potential points of failure that might be missed during standard physical inspections.

Proactive Component Reinforcement

Once the machine learning model identifies a vulnerable component, maintenance teams can take immediate action. This allows for the proactive reinforcement of parts before they fail in the real world, preventing costly unplanned downtime.

Understanding the Strategic Value

Significant Cost Reductions

Implementing this simulation-based approach has a measurable impact on the bottom line. By optimizing maintenance schedules and preventing failures, organizations can reduce maintenance costs by 40%.

Asset Preservation

Traditional stress testing often degrades the very equipment it is meant to protect. Digital Twins eliminate this paradox, ensuring that the physical asset remains untouched and operational while the virtual model absorbs the stress of testing.

Making the Right Choice for Your Goal

To maximize the benefits of Digital Twin technology and machine learning, align your strategy with your specific operational needs.

- If your primary focus is cost efficiency: Leverage machine learning predictions to optimize maintenance schedules, aiming for the potential 40% reduction in maintenance expenses.

- If your primary focus is asset longevity: Utilize the virtual replica for all stress testing to ensure the physical equipment is never exposed to unnecessary damaging scenarios.

Adopting a virtual simulation strategy transforms maintenance from a reactive burden into a predictive advantage.

Summary Table:

| Feature | Physical Stress Testing | Digital Twin + Machine Learning |

|---|---|---|

| Risk Level | High (Potential for damage) | Zero (Risk-free simulation) |

| Cost Impact | High repair/replacement costs | Up to 40% reduction in maintenance costs |

| Maintenance Style | Reactive (Fix after failure) | Proactive (Predictive reinforcement) |

| Asset Longevity | Reduced due to testing stress | Maximized via virtual-only testing |

| Data Insights | Limited to visible wear | Deep predictive risk analysis |

Elevate Your Lab Reliability with KINTEK

Don’t let unplanned downtime stall your progress. KINTEK combines world-class manufacturing with the latest technological insights to provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable solutions tailored to your unique research needs, our expert R&D team is here to support you.

Ready to optimize your thermal processes? Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the temperature field provided by a High-Temperature Reaction Furnace promote pore development? 700-800°C Mastery

- What is the function of an industrial resistance furnace in HPDC magnesium melting? Master Thermal Precision

- What is the significance of the 200 °C calcination for Fe3O4/biochar? Enhancing Stability and Magnetic Recovery

- What role does physical homogenization via planetary ball milling play in LFP precursors? Maximize Your Battery Quality

- What are the equipment requirements for high-temperature furnaces during magnetic biochar synthesis? Find the key specs.

- Why is specialized dewaxing and annealing necessary for glass-to-metal seals? Ensure Hermeticity and Clarity

- Why are nitrogen cylinders and flow meters necessary during biomass pyrolysis? Control Atmosphere for Peak Yields

- Why is a laboratory vacuum drying oven essential for the swelling-encapsulation-shrinkage method? Lock-in Film Quality