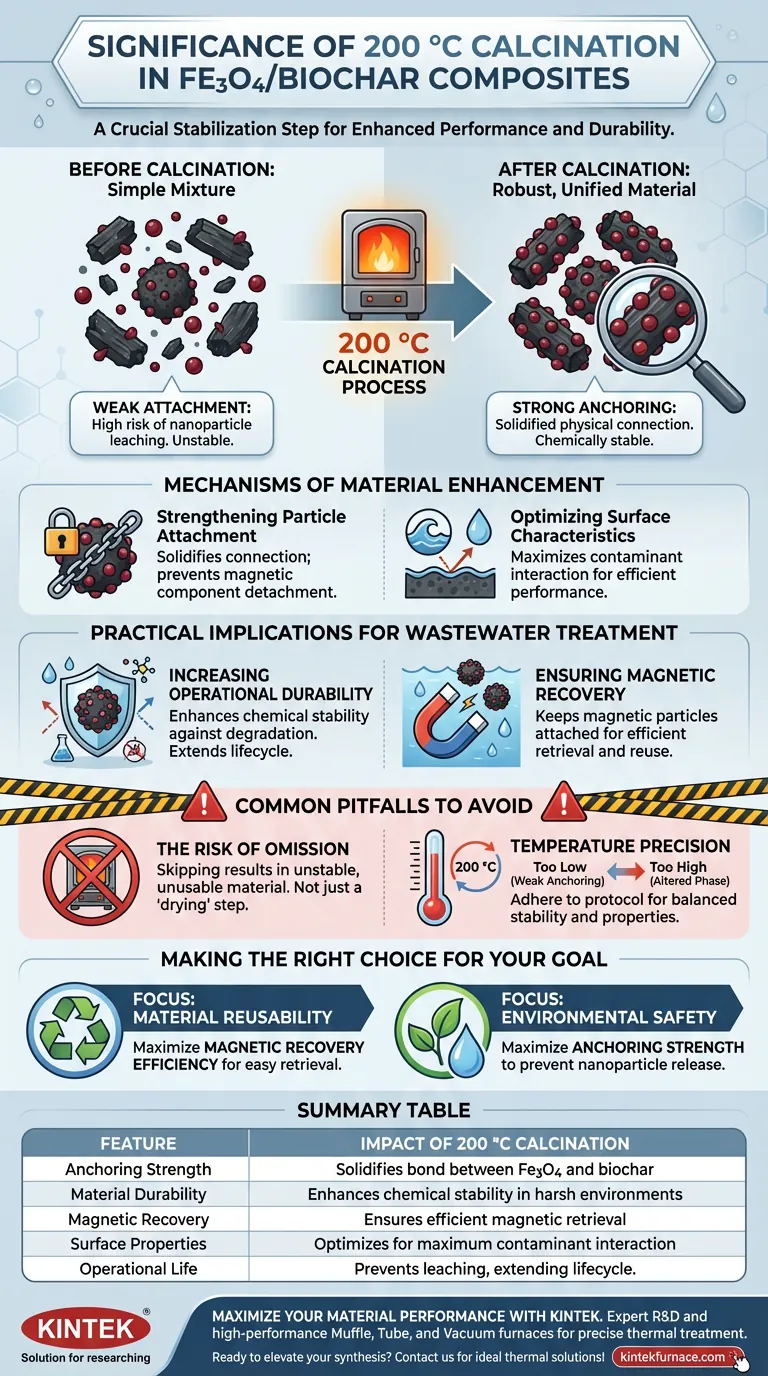

The 200 °C calcination process serves as a critical stabilization step for Fe3O4/biochar composite materials. It is primarily responsible for significantly enhancing the anchoring strength of iron oxide (Fe3O4) nanoparticles onto the biochar matrix, while simultaneously improving the overall chemical stability of the final composite.

The core purpose of this thermal treatment is to transform a simple mixture into a robust, unified material. By subjecting the composite to 200 °C, you optimize surface properties to ensure magnetic particles remain attached during use, directly enabling effective magnetic recovery and long-term durability in wastewater treatment.

Mechanisms of Material Enhancement

Strengthening Particle Attachment

The primary function of the 200 °C calcination is to solidify the physical connection between the magnetic components and the carbon support.

Without this thermal step, the Fe3O4 nanoparticles may only be loosely associated with the biochar. The heating process increases the anchoring strength, effectively locking the nanoparticles onto the biochar matrix. This prevents the magnetic material from detaching or "leaching" out during operation.

Optimizing Surface Characteristics

Beyond simple attachment, this process acts as a surface modification treatment.

Calcination modifies the surface characteristics of the Fe3O4/biochar material. This optimization is essential for maximizing the interaction between the composite and the contaminants it is designed to remove, ensuring the material performs efficiently in its intended environment.

Practical Implications for Wastewater Treatment

Increasing Operational Durability

For a composite material to be viable in industrial applications, it must withstand harsh conditions.

The calcination process significantly improves the durability of the composite. By enhancing chemical stability, the material becomes more resistant to degradation when exposed to wastewater environments. This extends the lifecycle of the material, making it a more practical solution for continuous treatment cycles.

Ensuring Magnetic Recovery

One of the main advantages of Fe3O4 composites is the ability to remove them from water using magnets.

If the anchoring strength is weak, the magnetic particles will separate from the biochar, making magnetic retrieval impossible. The 200 °C treatment ensures the magnetic recovery efficiency remains high by keeping the magnetic iron oxide firmly bonded to the adsorbent biochar.

Common Pitfalls to Avoid

The Risk of Omission

It is a common error to view low-temperature calcination as an optional "drying" step.

Skipping this 200 °C phase does not just result in a wetter material; it results in a chemically unstable composite. Without this specific thermal input, the material lacks the structural integrity required for reuse, leading to rapid performance loss and potential contamination of the water with loose iron particles.

Temperature Precision

While the reference highlights 200 °C, precise control is implied.

Deviating significantly from this temperature could fail to achieve the necessary anchoring (if too low) or potentially alter the chemical phase of the components (if too high). Adhering to the specific 200 °C protocol is necessary to balance stability with the preservation of the material's magnetic properties.

Making the Right Choice for Your Goal

This process is not merely about heating; it is about engineering a material for longevity and recovery.

- If your primary focus is Material Reusability: Ensure the 200 °C calcination is complete to maximize magnetic recovery efficiency, allowing you to easily retrieve and reuse the composite.

- If your primary focus is Environmental Safety: Prioritize this step to maximize anchoring strength, preventing the release of nanoparticles into the treated wastewater.

The 200 °C calcination is the defining factor that transitions Fe3O4/biochar from a laboratory concept to a durable, recoverable tool for real-world water treatment.

Summary Table:

| Feature | Impact of 200 °C Calcination |

|---|---|

| Anchoring Strength | Solidifies the bond between Fe3O4 nanoparticles and biochar matrix |

| Material Durability | Enhances chemical stability for use in harsh wastewater environments |

| Magnetic Recovery | Ensures particles stay attached for efficient magnetic retrieval |

| Surface Properties | Optimizes characteristics for maximum contaminant interaction |

| Operational Life | Prevents nanoparticle leaching, extending the material's lifecycle |

Maximize Your Material Performance with KINTEK

Achieving the perfect 200 °C calcination requires precision and reliability. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnace systems designed to provide the thermal accuracy your research demands. Whether you are developing Fe3O4/biochar composites or advanced catalysts, our customizable lab high-temp furnaces ensure consistent anchoring strength and material stability.

Ready to elevate your material synthesis? Contact KINTEK today to find the ideal thermal solution for your unique laboratory needs!

Visual Guide

References

- Biomass-Derived Magnetic Fe3O4/Biochar Nanoparticles from Baobab Seeds for Sustainable Wastewater Dye Remediation. DOI: 10.3390/ijms26178499

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the effect of 750°C to 950°C on activated carbon? Optimize Pore Structure & Surface Area

- Why is high-precision temperature control of the heating base critical during FTO spray pyrolysis? Maximize Film Quality

- What is the function of a high-precision electric oven in ZnO-CuO synthesis? Expert Thermal Control for Nanosheets

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the function of an inert gas supply system in black liquor pyrolysis? Achieve Precise Atmospheric Control

- Why is an equivalent diffusion combustion heat source term integrated into the furnace temperature field simulation?

- What is the purpose of using nitrogen cylinders and flowmeters? Ensure Superior Carbon Fiber Recovery

- Why is an incubator required for VP-FSCM? Master Curing Controls for Superior Soil Solidification Results