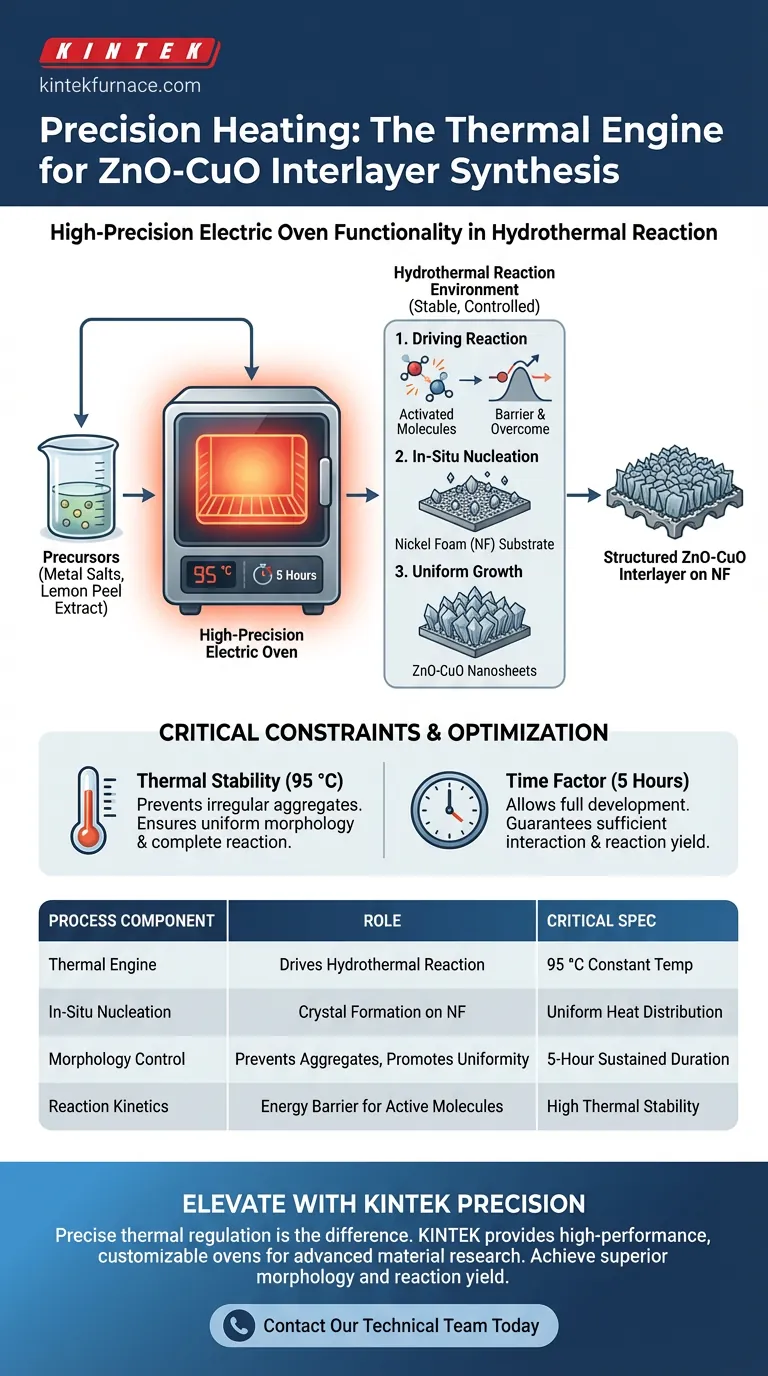

A high-precision electric oven serves as the stable thermal engine required to drive the hydrothermal reaction for ZnO-CuO synthesis. It creates a controlled environment where metal salts and active molecules from Lemon Peel Extract (LPE) interact at a constant 95 °C for a duration of 5 hours. This specific thermal regulation is vital for the in-situ nucleation and growth of uniform nanosheets on Nickel Foam (NF) substrates.

The oven’s primary function is to maintain strict thermal stability over a sustained period. This consistency is what transforms a chaotic mixture of precursors into structured, uniform nanosheets rather than irregular aggregates.

The Role of Controlled Thermal Energy

To understand the oven's importance, one must look at how it influences the chemical dynamics of the synthesis.

Driving the Chemical Reaction

The electric oven provides the energy activation barrier needed to initiate the reaction between the metal salts in the precursor solution and the active molecules in the Lemon Peel Extract.

Without this sustained heat, the precursors would remain inert or react too slowly to form the desired compound.

Facilitating In-Situ Nucleation

The process relies on in-situ nucleation, meaning the crystals begin to form directly on the Nickel Foam substrate rather than precipitating randomly in the solution.

The mild, uniform heating provided by the oven encourages these nuclei to attach to the NF lattice, serving as the foundation for subsequent crystal growth.

Promoting Uniform Growth

Once nucleation occurs, the oven ensures the continuous growth of ZnO-CuO nanosheets.

By keeping the temperature constant, the rate of crystal growth remains steady, resulting in nanosheets that are uniform in size and thickness.

Understanding the Constraints

While the concept of heating is simple, the requirement for "high precision" highlights specific operational constraints.

The Importance of Thermal Stability

A standard oven may fluctuate significantly around the set point, but this synthesis requires a constant 95 °C.

Significant deviations in temperature could alter the reaction kinetics, potentially leading to uneven nanosheet distribution or incomplete reactions.

The Time Factor

The process requires this specific temperature to be held for exactly 5 hours.

This duration is critical to allow the reaction to reach completion, ensuring that the nanosheets fully develop and cover the Nickel Foam substrate adequately.

Optimizing the Synthesis Process

To achieve the best results in fabricating ZnO-CuO interlayers, you must prioritize the stability of your reaction environment.

- If your primary focus is Morphology: Ensure the oven is calibrated to maintain exactly 95 °C, as fluctuations will disrupt the uniformity of the nanosheets.

- If your primary focus is Reaction Yield: Strictly adhere to the 5-hour duration to guarantee sufficient interaction between the metal salts and the LPE.

Precision heating is the bridge between a raw precursor solution and a structured, functional nanomaterial.

Summary Table:

| Process Component | Role in Synthesis | Critical Specification |

|---|---|---|

| Thermal Engine | Drives hydrothermal reaction between metal salts & LPE | 95 °C Constant Temp |

| In-Situ Nucleation | Ensures crystal formation directly on Nickel Foam (NF) | Uniform Heat Distribution |

| Morphology Control | Prevents irregular aggregates; promotes nanosheet uniformity | 5-Hour Sustained Duration |

| Reaction Kinetics | Provides energy barrier for active molecule interaction | High Thermal Stability |

Elevate Your Material Synthesis with KINTEK Precision

Precise thermal regulation is the difference between chaotic aggregates and structured nanosheets. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, and Vacuum systems—including customizable high-precision electric ovens—tailored for hydrothermal synthesis and advanced material research.

Ready to achieve superior morphology and reaction yield? Contact our technical team today to discover how our customizable high-temperature lab furnaces can optimize your ZnO-CuO interlayer fabrication and beyond.

Visual Guide

References

- Muhammad Ali Bhatti, Zafar Hussain Ibupoto. Advanced NiCo2O4 /ZnO-CuO/NF composite for high-performance asymmetric supercapacitor and efficient oxygen evolution reaction applications. DOI: 10.1007/s42114-025-01238-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is the importance of transferring freshly deposited CuO films directly into a 125°C oven? Ensure Film Adhesion

- How does a bias power supply influence AlCrSiWN coatings? Master Ion Bombardment for Superior Durability

- Why is 10^-6 mbar pressure required for CZTS PLD? Ensure Pure, High-Efficiency Thin Film Deposition

- What is the primary role of a vacuum drying oven in WO3 nanostructure preparation? Achieve Perfect Morphology

- How is the pore structure of EN-LCNF characterized? Advanced BET and DFT Analysis of Carbon Nanosheets

- What is the purpose of mixing aluminum and iron powders at a specific atomic ratio? Optimize Al-Fe Alloy Phases

- How does a precision pressure-controlled oxidation device increase carbon chain yield? Optimize Your Annealing Process

- What advantages does a vacuum oven offer over a standard oven for V2CTx MXene films? Protect Your Material Quality