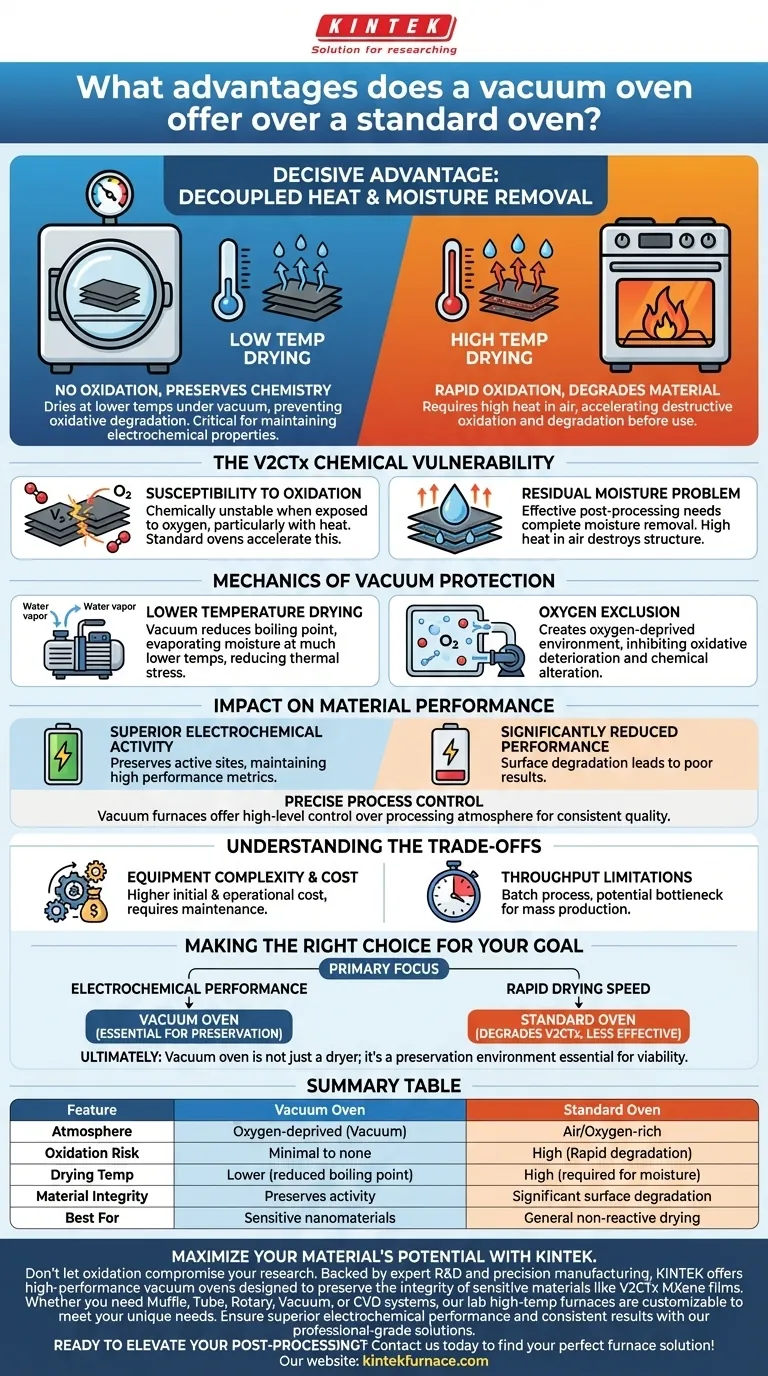

The decisive advantage of a vacuum oven lies in its ability to dry V2CTx MXene films without exposing them to destructive oxidation. Unlike standard ovens, a vacuum oven allows for the removal of residual moisture at significantly lower temperatures within an oxygen-deprived environment, which is critical for preserving the material's electrochemical properties.

By decoupling heat from moisture removal, vacuum ovens prevent the rapid oxidative degradation that occurs when V2CTx is exposed to air at high temperatures. This preservation of chemical integrity is the single most important factor in maintaining the film's superior electrochemical activity.

The Chemical Vulnerability of V2CTx

Susceptibility to Oxidation

V2CTx materials are chemically unstable when exposed to oxygen, particularly during heating.

Standard ovens circulate heated air, which accelerates the oxidation process. This leads to the physical and chemical degradation of the film before it is even put to use.

The Problem with Residual Moisture

Effective post-processing requires the complete removal of residual moisture to stabilize the film.

However, trying to drive off this moisture using high heat in a standard atmosphere often destroys the material structure it is meant to preserve.

Mechanics of Vacuum Protection

Lower Temperature Drying

A vacuum environment reduces the boiling point of water.

This allows the oven to effectively evaporate residual moisture at much lower temperatures than a standard oven would require. This reduces thermal stress on the V2CTx film.

Oxygen Exclusion

The most critical function of the vacuum is the physical removal of the atmosphere.

By creating a vacuum, you eliminate the presence of oxygen. This inhibits oxidative deterioration, ensuring the drying process does not chemically alter the MXene sheets.

Impact on Material Performance

Preserving Electrochemical Activity

The primary reason for selecting V2CTx is often its specific electrochemical capabilities.

Because the vacuum oven prevents oxidation, it helps maintain superior electrochemical activity. A film dried in a standard oven would likely exhibit significantly reduced performance metrics due to surface degradation.

Precise Process Control

Beyond simple drying, vacuum furnaces offer high-level control over the processing atmosphere.

This precision enhances the overall quality of the treated material, ensuring consistent performance across different batches of V2CTx films.

Understanding the Trade-offs

Equipment Complexity and Cost

Vacuum ovens are inherently more complex than standard thermal ovens.

They require reliable vacuum pumps, intricate sealing systems, and regular maintenance to ensure the atmosphere remains compromised. This represents a higher initial investment and operational cost.

Throughput Limitations

Vacuum processing is typically a batch process rather than a continuous one.

If you are moving from laboratory scale to mass production, the time required to pump down the chamber and break the vacuum can create a bottleneck compared to continuous conveyor-style standard ovens.

Making the Right Choice for Your Goal

When processing sensitive nanomaterials like V2CTx, the choice of equipment dictates the final quality of the product.

- If your primary focus is electrochemical performance: You must use a vacuum oven to prevent oxidation and preserve the active sites on the MXene material.

- If your primary focus is rapid drying speed: Recognize that while a standard oven is faster, it will likely degrade the V2CTx, rendering it less effective for high-performance applications.

Ultimately, for V2CTx MXene films, the vacuum oven is not just a drying tool; it is a preservation environment essential for material viability.

Summary Table:

| Feature | Vacuum Oven | Standard Oven |

|---|---|---|

| Atmosphere | Oxygen-deprived (Vacuum) | Air/Oxygen-rich |

| Oxidation Risk | Minimal to none | High (Rapid degradation) |

| Drying Temp | Lower (reduced boiling point) | High (required for moisture) |

| Material Integrity | Preserves electrochemical activity | Significant surface degradation |

| Best For | Sensitive nanomaterials (MXenes) | General non-reactive drying |

Maximize Your Material’s Potential with KINTEK

Don't let oxidation compromise your research. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance vacuum ovens designed to preserve the integrity of sensitive materials like V2CTx MXene films.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique processing needs. Ensure superior electrochemical performance and consistent results with our professional-grade solutions.

Ready to elevate your post-processing? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Reagan A. Beers, Jessica R. Ray. Chemical Intercalant Affects the Structural Properties and Aqueous Stability of V<sub>2</sub>CT<sub>x</sub> MXene. DOI: 10.1002/admi.202500145

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is high-purity argon gas required during the calcination of TiO2/MoSe2 materials? Protect Your Sensor's Integrity

- What is the role of temperature control in MCM-41 synthesis? Master Precision Pore Engineering

- How do chill rings specifically influence the temperature field distribution? Expert Insight into Crystal Casting

- Why is an auxiliary gas supply device required for oil sludge pyrolysis? Ensure Stable Thermal Balance

- What environmental factors can be controlled in a vacuum chamber? Master Pressure, Temperature, Humidity, and Radiation

- What is the critical role of a controlled temperature incinerator in rice husk ash? Mastery of Amorphous Silica

- Why is pre-sintering of Ga2O3 raw material powder required? Unlock Beta-Phase Stability for High-Performance Thin Films

- What are batch catalytic debinding ovens used for? Speed Up MIM/CIM with Low-Temp Debinding