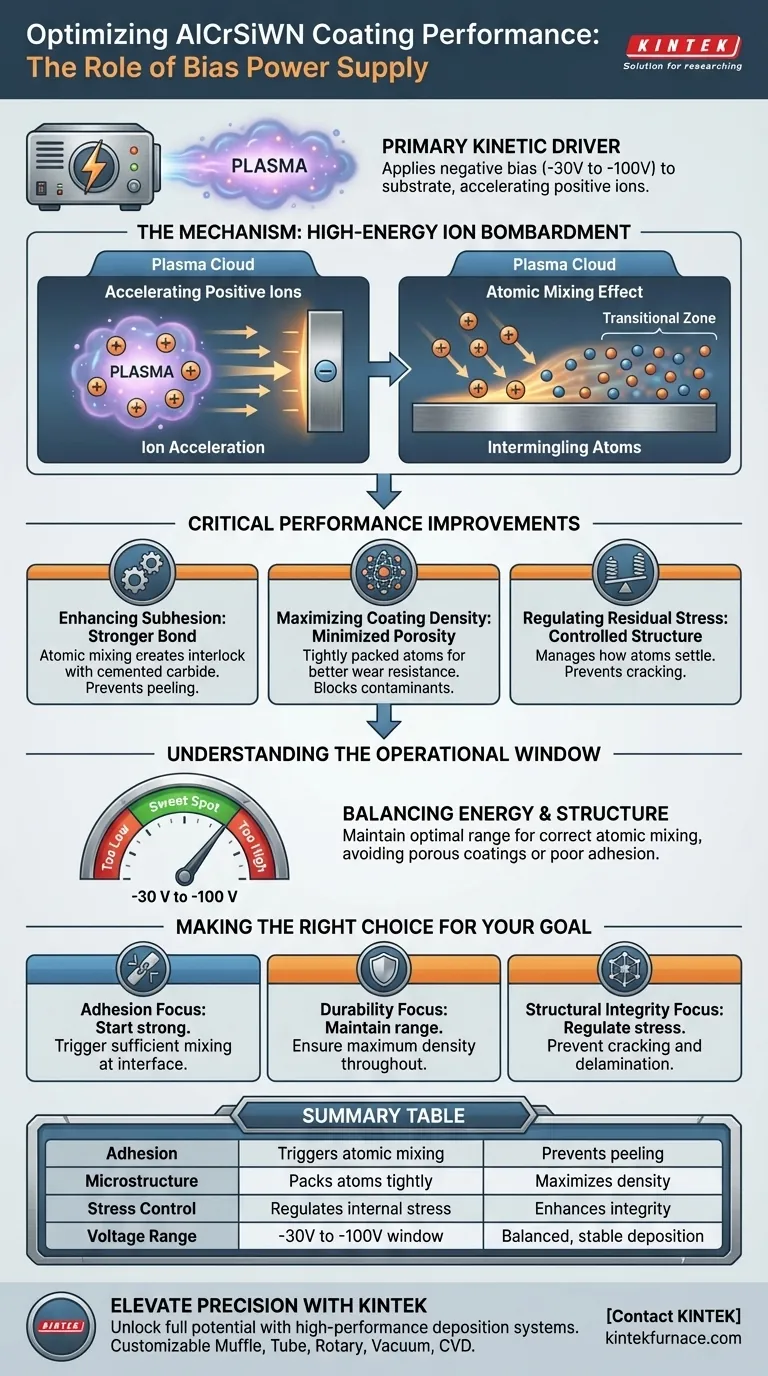

A bias power supply serves as the primary kinetic driver for coating quality during the deposition process. By applying a negative bias voltage—typically between -30 V and -100 V—to the substrate, it accelerates positive ions from the plasma to bombard the tool surface with high energy. This bombardment triggers an atomic mixing effect that is essential for structural integrity.

The bias power supply does not merely deposit material; it actively modifies the coating's microstructure through high-energy ion bombardment. This process is the key to transforming a loose collection of atoms into a dense, highly adherent AlCrSiWN layer with optimized internal stress.

The Mechanism: High-Energy Ion Bombardment

Accelerating Positive Ions

The core function of the bias power supply is to create a controlled electrical potential. By establishing a negative bias on the substrate, it acts as a magnet for positive ions within the plasma cloud.

These ions are accelerated toward the tool surface at high velocities. This kinetic energy is the catalyst for the physical changes in the coating.

The Atomic Mixing Effect

When these accelerated ions impact the surface, they do not just sit on top; they collide with existing atoms. This creates a phenomenon known as atomic mixing.

This intermingling of atoms at the interface is critical. It blurs the distinct line between the substrate and the coating, creating a transitional zone rather than a sharp boundary.

Critical Performance Improvements

Enhancing Subhesion

The atomic mixing effect significantly improves the bond between the AlCrSiWN coating and the cemented carbide substrate.

Without this high-energy bombardment, the coating acts as a distinct layer that can easily peel. The bias creates a mechanical and atomic interlock, ensuring the coating remains fixed under stress.

Maximizing Coating Density

The continuous bombardment during deposition packs the atoms tightly together. This minimizes porosity and voids within the AlCrSiWN structure.

A denser coating translates directly to better wear resistance. It prevents environmental contaminants from penetrating the layer and degrading the tool underneath.

Regulating Residual Stress

Deposition naturally creates stress within a material, which can lead to cracking. The bias power supply plays a vital role in regulating internal residual stress.

By controlling the energy of the arriving ions, the process manages how atoms settle into the lattice. This prevents the buildup of excessive destructive forces inside the coating layer.

Understanding the Operational Window

The Voltage "Sweet Spot"

The benefits of ion bombardment rely on maintaining a specific voltage range, identified in the reference as -30 V to -100 V.

Operating within this window is necessary to achieve the correct level of atomic mixing. If the energy is too low, the ions will lack the momentum required to densify the coating or intermix with the substrate.

Balancing Energy and Structure

The goal is controlled regulation, not aggressive etching. The power supply must provide enough energy to compact the coating and manage stress without disrupting the deposition stability.

Failure to maintain the bias within the optimal range risks producing a coating that is either too porous (low density) or adheres poorly to the cemented carbide substrate.

Making the Right Choice for Your Goal

To maximize the performance of AlCrSiWN coatings, you must view the bias power supply as a tool for microstructural engineering.

- If your primary focus is Adhesion: Ensure the bias is set to trigger sufficient atomic mixing at the start of the process to lock the coating to the cemented carbide.

- If your primary focus is Durability: Maintain the bias within the -30 V to -100 V range throughout deposition to ensure maximum density and minimal porosity.

- If your primary focus is Structural Integrity: Use the bias voltage to actively regulate internal residual stress, preventing premature cracking or delamination.

Ultimately, the bias power supply is the defining factor that separates a superficial surface layer from a robust, industrial-grade protective coating.

Summary Table:

| Feature | Impact of Bias Power Supply | Key Benefit |

|---|---|---|

| Adhesion | Triggers atomic mixing effect at substrate interface | Prevents coating peeling and delamination |

| Microstructure | High-energy ion bombardment packs atoms tightly | Maximizes coating density and minimizes porosity |

| Stress Control | Regulates internal residual stress in the lattice | Prevents cracking and enhances structural integrity |

| Voltage Range | Optimal window of -30 V to -100 V | Ensures balanced energy for stable deposition |

Elevate Your Coating Precision with KINTEK

Unlock the full potential of your AlCrSiWN coatings with high-performance deposition equipment designed for precision. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique thin-film and material science needs.

Whether you are looking to optimize ion bombardment or achieve superior adhesion on cemented carbide substrates, our technical experts are ready to help. Contact KINTEK today to discover how our advanced furnace technology can transform your research and production outcomes.

Visual Guide

References

- Feng Guo. Research on the Performance of AlCrSiWN Tool Coatings for Hardened Steel Cutting. DOI: 10.62051/ijmee.v6n2.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- Why is an industrial-grade drying oven necessary for biomass activation? Ensure Structural Integrity & Yield

- How does the ramp rate affect LDO properties? Master Rapid Thermal Control for 69% More Efficiency

- What is the necessity of the subsequent pyrolysis step in ZnS-CFC preparation? Unlocking High-Performance Carbonization

- How does a high-precision reaction system aid methane CLR research? Unlock Advanced Syngas Insights

- What are the core technical advantages of single-step microwave furnace sintering for SSBSN ceramics?

- Why is precise temperature control necessary in a drying oven for MOF precursors? Ensure Nanopore Integrity

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- What advantages does tilting mirror technology provide for the growth of large-diameter crystals? Achieve Scale & Purity