Tilting mirror technology fundamentally improves crystal growth by introducing asymmetric heat input to the melt zone. This thermal manipulation allows operators to actively reshape the solid-liquid interface, directly solving the limitations of internal cracking and size constraints in large-diameter production.

By shifting the solid-liquid interface from a problematic convex shape to a more ideal profile, tilting mirrors stabilize internal convection. This capability is the specific mechanism that enables the production of larger, crack-free crystals with superior internal uniformity.

Controlling Thermal Dynamics

To understand the advantages of tilting mirrors, you must first understand how they alter the physics of the molten zone.

Asymmetric Heat Input

Standard optical floating-zone systems often apply heat symmetrically. Tilting mirrors, however, allow for the introduction of asymmetric heat input parameters. This capability breaks the rigid thermal symmetry that can limit process control.

Modifying Convection Patterns

The introduction of thermal asymmetry changes the fluid dynamics within the melt. It directly modifies the internal convection patterns, changing how material flows and mixes before it solidifies.

Optimizing the Solid-Liquid Interface

The most critical advantage of this technology is its ability to dictate the geometry of the freezing front.

Correcting Convex Interfaces

In traditional large-diameter growth, the solid-liquid interface tends to form a convex shape. This curvature is often unstable and prone to inducing stress.

Achieving an Ideal Profile

Tilting mirrors regulate the shape of this interface, transforming it from convex to a more ideal profile. This geometric correction is the foundational requirement for stable growth at larger scales.

Tangible Outcomes for Production

The physical changes to heat and convection translate into specific, high-value improvements in the final product.

Mitigating Internal Cracking

Large-diameter crystals are notoriously prone to fracturing during cooling. By precisely controlling the interface curvature, this technology effectively addresses internal cracking issues.

Increasing Uniformity and Size

Stability at the interface leads to consistency in the lattice. This results in significantly higher crystalline uniformity throughout the boule. Furthermore, it increases the maximum achievable diameter, allowing for the growth of crystals that were previously impossible to stabilize.

Understanding the Operational Trade-offs

While the benefits are significant, introducing this technology adds a layer of complexity to the growth process.

Dependency on Precision

The benefits of this system are not automatic; they require precise control over the interface curvature. Mismanagement of the mirror tilt can fail to correct the convex shape or potentially introduce new instabilities.

Parameter Complexity

Moving from symmetric to asymmetric heat inputs increases the number of variables an operator must manage. You are trading the simplicity of a static system for the dynamic regulation required to maintain an ideal interface profile.

Making the Right Choice for Your Goal

Determining whether to implement tilting mirror technology depends on the specific limitations of your current crystal growth process.

- If your primary focus is Scaling Up: This technology is essential for increasing the maximum achievable diameter by stabilizing the melt where traditional methods fail.

- If your primary focus is Material Integrity: Use this method to regulate interface curvature, which is the primary lever for eliminating internal cracking and ensuring structural uniformity.

Mastering the shape of the solid-liquid interface is the definitive step toward high-yield, large-diameter crystal growth.

Summary Table:

| Feature | Advantage | Impact on Crystal Growth |

|---|---|---|

| Heat Input | Asymmetric thermal manipulation | Breaks rigid symmetry for better process control |

| Interface Shape | Corrects convex profiles to ideal geometry | Enables stable growth of larger diameters |

| Convection | Stabilizes internal fluid dynamics | Improves material mixing and internal uniformity |

| Integrity | Precision stress management | Mitigates internal cracking and structural defects |

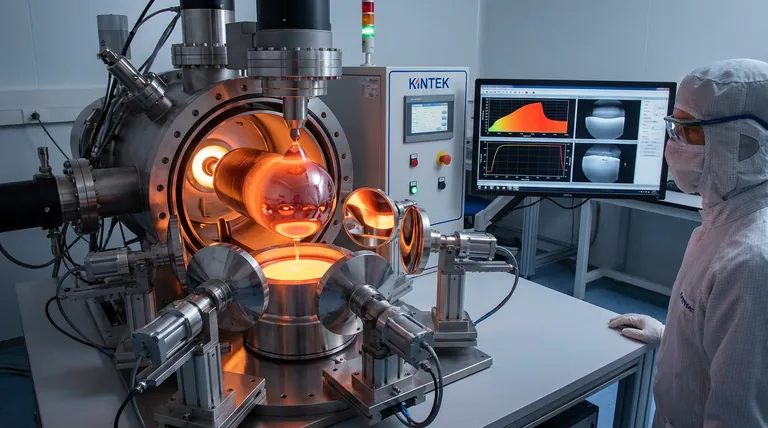

Unlock High-Precision Crystal Growth Today

Struggling with internal cracking or diameter limits in your Floating-Zone processes? KINTEK provides the advanced high-temperature solutions you need to master the solid-liquid interface.

Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for your unique laboratory requirements. Our specialized equipment is designed to help you achieve superior crystalline uniformity and scale your production efficiently.

Ready to optimize your thermal dynamics? Contact our experts at KINTEK today to find the perfect high-temperature furnace for your research!

References

- Naoki Kikugawa. Recent Progress of Floating-Zone Techniques for Bulk Single-Crystal Growth. DOI: 10.3390/cryst14060552

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do thermal systems reveal anti-spalling mechanisms in CDE concrete? Explore Advanced Material Resilience

- How does a high-precision temperature control system assist in evaluating the thermal management capabilities of phosphor materials? Pinpoint Performance for Solar Cells.

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- What is the purpose of using a vacuum dryer for PU and AlN composite sheets? Enhance Thermal & Structural Integrity

- Why is a slow heating rate utilized for rice husk biochar? Optimize Pore Structure and Adsorption Performance

- What role does temperature control play in biomass pyrolysis for biochar? Achieve Optimal Pore Structure & Yield

- What happens during the recovery stage of the annealing process? Unlock Stress Relief and Material Restoration

- What are the critical functions of cold recycled gas nozzles? Optimize Oil Shale Retorting and Energy Recovery