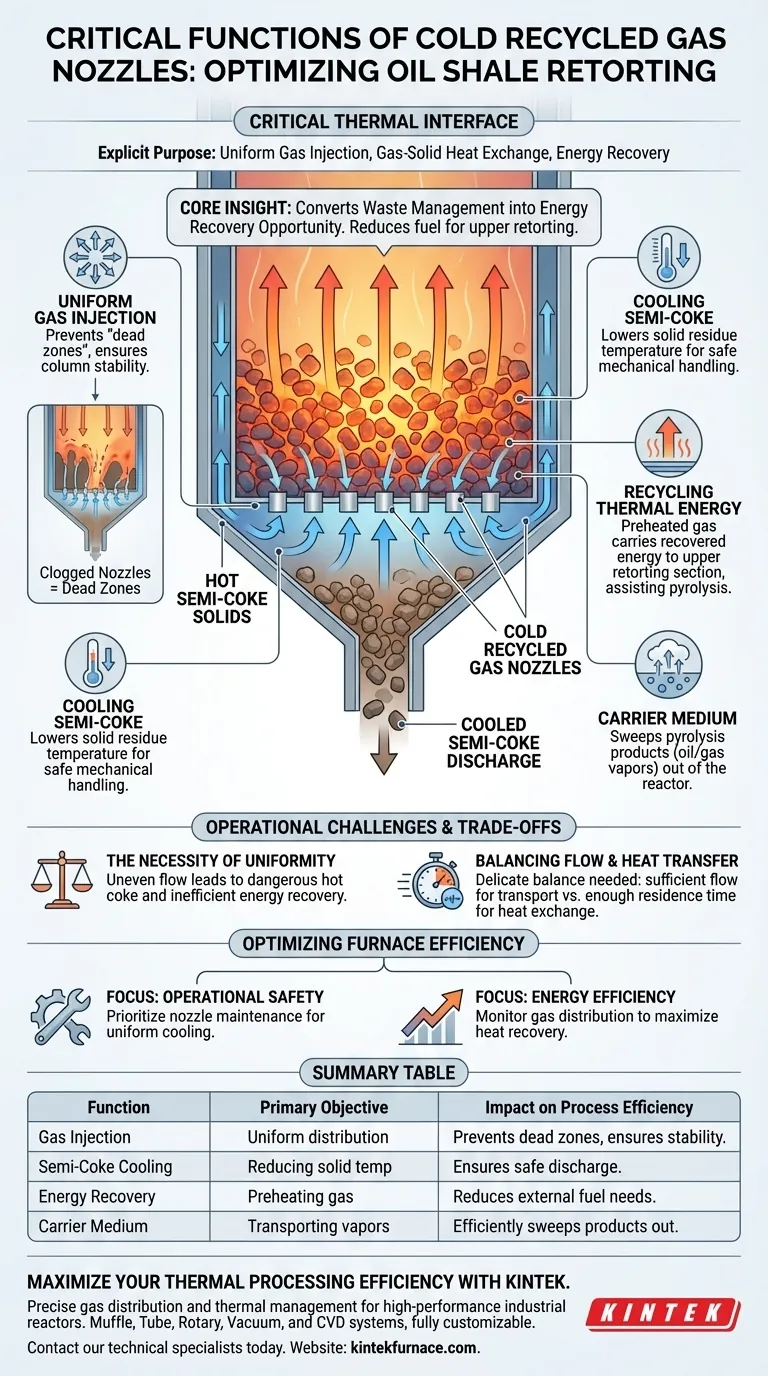

Cold recycled gas nozzles function as the critical thermal interface at the bottom of an oil shale retorting furnace. Their explicit purpose is to uniformly inject gas into the cooling section, facilitating a gas-solid heat exchange that cools semi-coke to a safe discharge temperature while simultaneously recovering thermal energy.

Core Insight: These nozzles convert a waste management step into an energy recovery opportunity. By transferring heat from the exiting solids to the incoming gas, they reduce the fuel required to heat the raw shale in the upper retorting zone.

The Dual Role of Cooling and Heating

Facilitating Uniform Gas Injection

The primary mechanical function of these nozzles is to distribute recycled gas evenly across the bottom of the furnace. Uniformity is non-negotiable here.

Without consistent distribution, the furnace develops "dead zones" where solids remain too hot, compromising the stability of the entire column.

Cooling Semi-Coke for Discharge

The immediate operational goal is lowering the temperature of the semi-coke (the solid residue left after retorting).

The cold gas passes through the hot semi-coke bed, absorbing heat through direct contact. This ensures the solids reach a specific target temperature, making them safe for mechanical discharge and handling.

Recycling Thermal Energy

As the gas cools the semi-coke, it is conversely preheated. This nozzle system effectively captures thermal energy that would otherwise be lost with the waste solids.

This preheated gas carries this recovered energy upward into the retorting section. There, it assists in heating the raw oil shale, directly contributing to the efficiency of the pyrolysis process.

Acting as a Carrier Medium

Beyond thermal management, the injected gas serves a crucial transport function.

As it rises through the furnace, the gas acts as a carrier medium. It sweeps up the pyrolysis products—specifically the oil and gas vapors generated in the upper sections—and helps transport them out of the reactor for processing.

Operational Challenges and Trade-offs

The Necessity of Uniformity

The effectiveness of the entire system relies on the nozzle's ability to maintain uniform flow.

If nozzles become clogged or are poorly designed, gas flow becomes channeled. This results in uneven cooling, meaning some semi-coke leaves the furnace dangerously hot while energy recovery becomes inefficient.

Balancing Flow and Heat Transfer

There is a delicate balance between gas velocity and heat exchange time.

The flow must be sufficient to carry pyrolysis products upward and cool the solids. However, the interaction must allow enough residence time for effective gas-solid heat transfer to occur.

Optimizing Furnace Efficiency

To maximize the performance of an oil shale retorting furnace, you must view these nozzles as heat exchangers rather than just outlets.

- If your primary focus is operational safety: Prioritize nozzle maintenance to ensure semi-coke is uniformly cooled to the target temperature before discharge to prevent equipment damage.

- If your primary focus is energy efficiency: Monitor gas distribution patterns to maximize the amount of heat recovered from the semi-coke and transferred to the upper retorting section.

Properly calibrated nozzles ensure the system remains thermally balanced and economically viable.

Summary Table:

| Function | Primary Objective | Impact on Process Efficiency |

|---|---|---|

| Gas Injection | Uniform distribution across furnace base | Prevents dead zones and ensures column stability |

| Semi-Coke Cooling | Reducing solid residue temperature | Ensures safe discharge and mechanical handling |

| Energy Recovery | Preheating gas via gas-solid exchange | Reduces external fuel needs for the pyrolysis zone |

| Carrier Medium | Transporting pyrolysis vapors | Efficiently sweeps oil and gas products out for processing |

Maximize Your Thermal Processing Efficiency with KINTEK

Precise gas distribution and thermal management are vital for high-performance industrial reactors. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other laboratory high-temperature furnaces—all fully customizable to meet your unique oil shale or material processing needs.

Ready to optimize your heat treatment results? Contact our technical specialists today to discover how our advanced furnace solutions can drive your project's success.

Visual Guide

References

- Lixin Zhao, Luwei Pan. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. DOI: 10.3390/sym17071055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does direct technical consultation support the acquisition of customized high-temperature furnace systems? Expert R&D

- What task does a laboratory blast drying oven perform in the preparation of copper oxide precursors? Prevent Clumping

- What technical advantages does a single-channel roller kiln offer? Optimize Your Fast Sintering Cycles

- Why is 800 °C Required for Ln-MoP@C Phosphorization? Unlock Superior Catalyst Engineering

- What function does a high-temperature furnace serve in alumina nanopowder decarbonization? Ensure Purity & Performance

- What are the advantages of the sol-gel nitrate combustion method? Achieve Atomic-Level Purity in Oxide Synthesis

- What heat treatment conditions are required for SDSS2507 solution treatment? Achieve Precise 1100°C Thermal Profiles

- What causes the increase in specific gravity of Moso Bamboo? Master Cellular Densification in Heat Treatment