Direct technical consultation serves as a formal validation mechanism that transforms complex research requirements into viable engineering specifications. It provides an in-depth channel for you to articulate unique laboratory needs—such as precise vacuum levels or specialized gas delivery architectures—ensuring the final equipment is technically accurate, traceable, and fully optimized for your specific application.

The consultation process moves beyond simple product selection to create a traceable engineering record. It ensures that every critical variable of your experiment is matched with expert R&D and manufacturing capabilities to guarantee reliability in demanding environments.

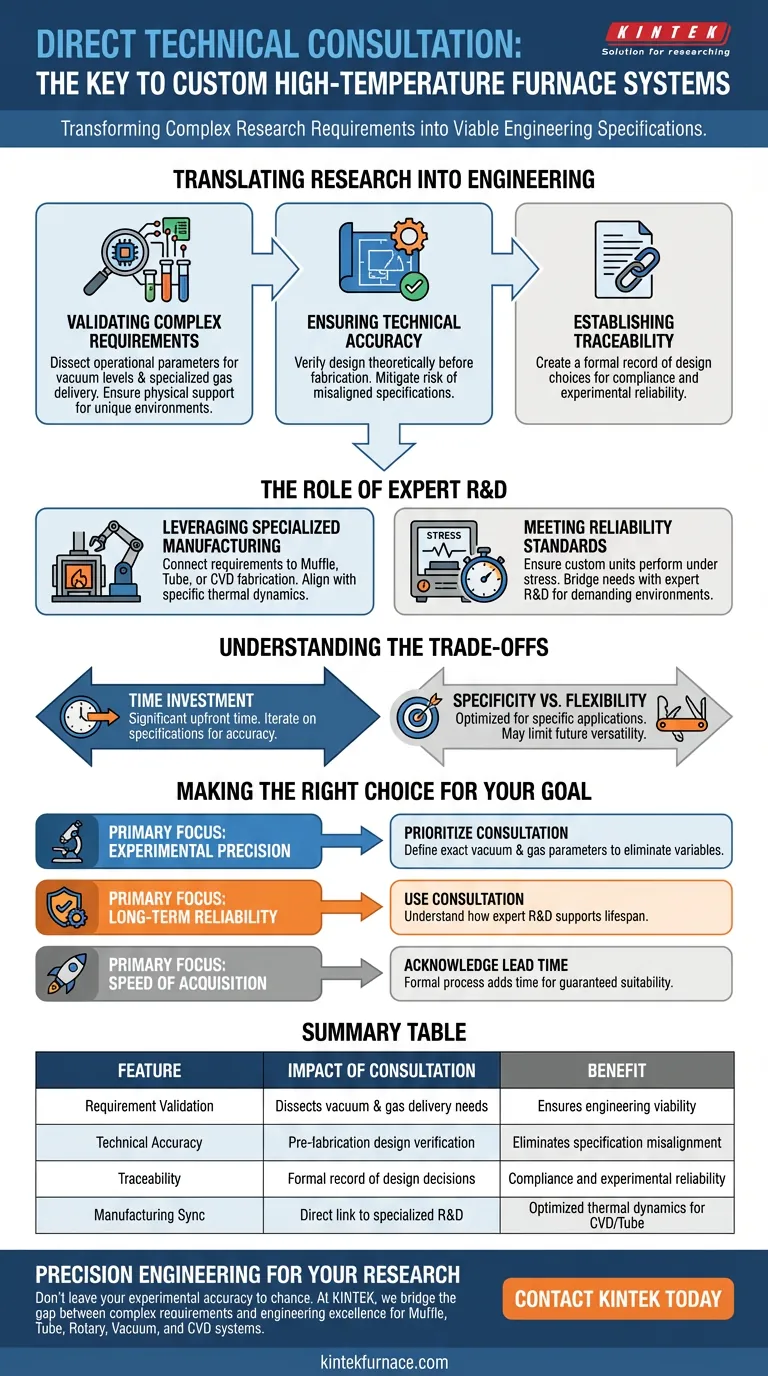

Translating Research into Engineering

Validating Complex Requirements

High-temperature furnace systems often require more than standard off-the-shelf configurations. Direct consultation allows you to dissect complex operational parameters, specifically regarding vacuum levels and gas delivery systems. This ensures that the equipment can physically support the unique chemical and thermal environments your research demands.

Ensuring Technical Accuracy

Customization introduces complexity, increasing the risk of misaligned specifications. A formal consultation ensures that the resulting system is technically accurate relative to your stated goals. This process verifies that the design theoretically works before metal is cut or heating elements are installed.

Establishing Traceability

For advanced research, the "why" behind a design decision is as important as the "what." Consultation provides a traceable record of design choices. This allows you to verify that the customized equipment is perfectly suited to your specialized applications and meets all compliance standards.

The Role of Expert R&D

Leveraging Specialized Manufacturing

The consultation process connects your requirements directly to specialized manufacturing processes. Whether you require Muffle, Tube, or CVD (Chemical Vapor Deposition) configurations, expert input ensures the fabrication aligns with the specific thermal dynamics of that furnace type.

Meeting Reliability Standards

Custom systems must still perform reliably under stress. Through expert Research and Development (R&D), manufacturers ensure that your custom unit meets rigorous performance and reliability standards. This bridge between your needs and their R&D team is critical for demanding laboratory and industrial environments.

Understanding the Trade-offs

The Time Investment

Engaging in deep technical consultation requires a significant investment of time upfront. Unlike purchasing a standard unit, you must be prepared to iterate on specifications to ensure the technical accuracy of the design.

Specificity vs. Flexibility

Highly customized systems are often designed for a very specific set of applications. While this optimizes performance for your current research, it may limit the versatility of the furnace for general-purpose tasks in the future.

Making the Right Choice for Your Goal

To determine how heavily you should rely on technical consultation, consider your project's primary constraints:

- If your primary focus is experimental precision: Prioritize consultation to define exact vacuum and gas delivery parameters, ensuring the system eliminates variables in your research.

- If your primary focus is long-term reliability: Use the consultation to understand how expert R&D and manufacturing processes will support the lifespan of your custom configuration.

- If your primary focus is speed of acquisition: Acknowledge that a formal, in-depth consultation process will add lead time to the project in exchange for guaranteed suitability.

The value of direct consultation lies in mitigating the risk that your specialized equipment fails to meet the physical demands of your research.

Summary Table:

| Feature | Impact of Consultation | Benefit |

|---|---|---|

| Requirement Validation | Dissects vacuum & gas delivery needs | Ensures engineering viability |

| Technical Accuracy | Pre-fabrication design verification | Eliminates specification misalignment |

| Traceability | Formal record of design decisions | Compliance and experimental reliability |

| Manufacturing Sync | Direct link to specialized R&D | Optimized thermal dynamics for CVD/Tube |

Precision Engineering for Your Research

Don’t leave your experimental accuracy to chance. At KINTEK, we bridge the gap between complex laboratory requirements and engineering excellence. Backed by expert R&D and specialized manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your exact specifications.

Our technical consultation ensures that every furnace we build—whether customized or standard—is optimized for your unique thermal and chemical environments. Contact KINTEK today to discuss your project needs and discover how our expert-led customization process can enhance your lab’s reliability and efficiency.

Visual Guide

References

- Cu‐Content Engineering in FeCoNiCuAl High‐Entropy Alloy Precursors: A Pathway to Advanced HEA‐Derived Sulfide Electrocatalysts for Efficient Oxygen Evolution Reaction. DOI: 10.1002/cctc.202500147

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a constant temperature incubator required for 10-week fungal testing of Moso Bamboo? Ensure Testing Accuracy

- Why is a silicone oil bath preferred for T5 aging of HPDC magnesium alloys? Precision Heat for Peak Strength

- What is the primary function of a forced convection oven in plant sample preparation? Ensure Accurate Data Every Time

- How does a rotary evaporator contribute to the concentration phase of TiO2 and ZrO2 pastes? Achieve Precision Viscosity

- How does a PID intelligent segmented temperature control system impact diamond tools? Precision Sintering Explained

- What is the impact of using a vacuum drying oven on CDI electrodes? Optimize Stability and Conductivity

- Why is niobium foil wrapped around niobium cavity flanges? Protect Your UHV Seals During Heat Treatment

- What role do high-temperature industrial furnaces play in the pretreatment of spodumene for lithium extraction?