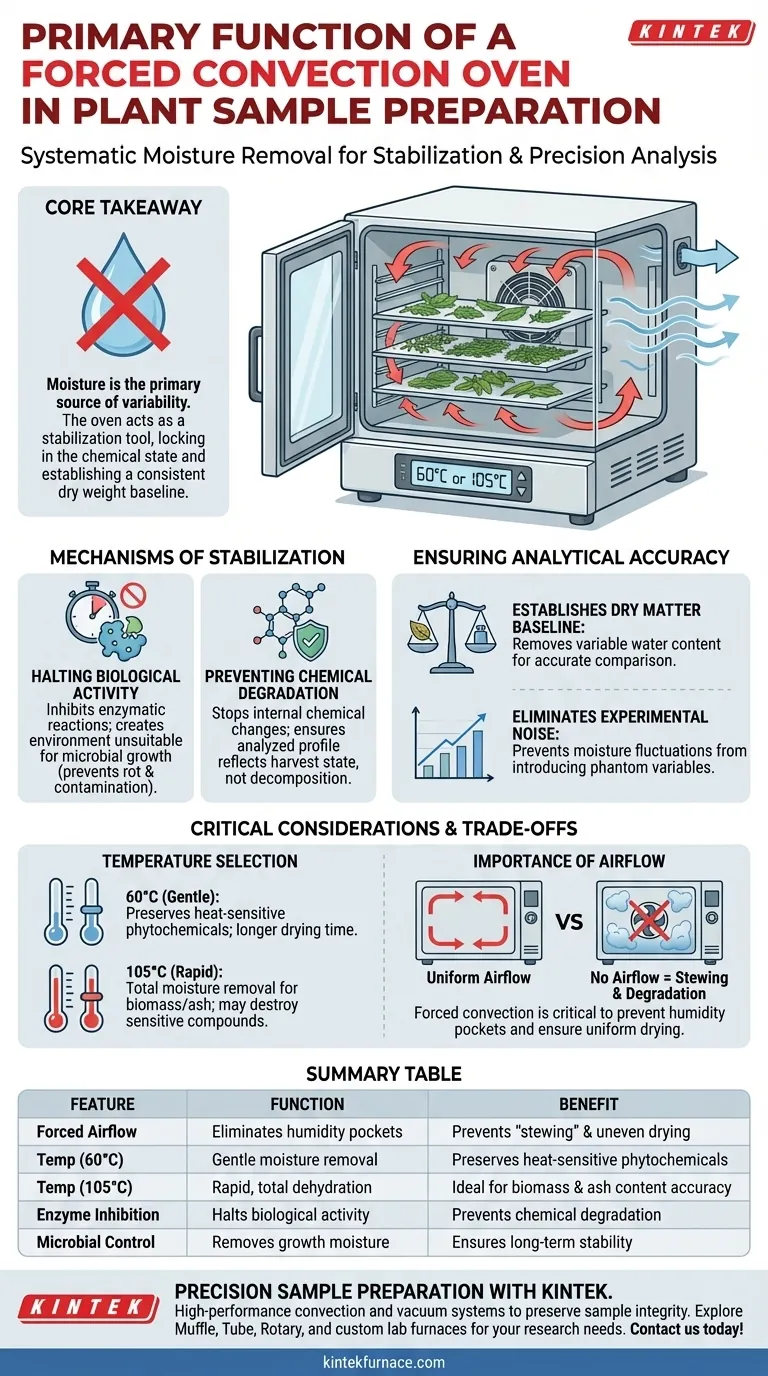

The primary function of a forced convection oven in plant sample preparation is to systematically remove free moisture through continuous, uniform heating. By maintaining specific temperatures—commonly 60°C or 105°C—the oven stabilizes the sample, preventing biological degradation and ensuring precise mass measurements for downstream analysis.

Core Takeaway Moisture is the primary source of variability in plant analysis. The forced convection oven acts as a stabilization tool, locking in the sample's chemical state by halting biological activity and establishing a consistent dry weight baseline to eliminate experimental errors.

The Mechanics of Sample Stabilization

Halting Biological Activity

Fresh plant tissue is biologically active and unstable. The oven’s heat serves to immediately inhibit enzymatic reactions that would otherwise break down the plant's active components. Furthermore, the drying process creates an environment unsuitable for microbial growth, preventing rot and contamination during storage.

Preventing Chemical Degradation

The integrity of your data depends on the integrity of the sample. By stopping internal chemical changes, the oven prevents the degradation of the specific active components you intend to study. This ensures that the chemical profile you analyze later reflects the state of the plant at the time of harvest, not a decomposed version of it.

Ensuring Analytical Accuracy

Establishing a Dry Matter Baseline

Water content in plants fluctuates significantly based on environmental conditions and harvest time. To compare samples accurately, you must eliminate this variable. The oven removes moisture to establish a stable baseline weight, allowing you to calculate results based on "dry matter" rather than total fresh weight.

Eliminating Experimental Noise

If moisture is not removed, it introduces phantom variables into your data. Fluctuations in humidity or incomplete drying can look like differences in sample mass or concentration. The forced convection process eliminates these errors, ensuring that observed differences between samples are real and not artifacts of water retention.

Critical Considerations and Trade-offs

Temperature Selection vs. Sample Integrity

While the primary reference notes temperatures of 60°C and 105°C, the choice involves a trade-off. 105°C is highly effective for rapid, total moisture removal for biomass determination. However, this high heat can destroy heat-sensitive compounds. 60°C is often a safer compromise for preserving active chemical constituents, though it requires a longer drying time.

The Importance of Airflow

The "forced convection" aspect is critical. Relying solely on heat without airflow can lead to pockets of humidity. If the oven is overloaded or airflow is blocked, samples may stew rather than dry, potentially leading to the very degradation or microbial growth you are trying to avoid.

Optimizing Your Preparation Protocol

To ensure the highest quality results, align your temperature settings with your specific analytical goals:

- If your primary focus is determining total biomass or ash content: Use 105°C to ensure rapid and complete removal of all moisture for the most accurate weight measurement.

- If your primary focus is analyzing heat-sensitive active components: Use 60°C to gently dry the sample, preserving delicate phytochemicals while still stabilizing the tissue.

Ultimately, proper drying is the foundational step that ensures your data is both reproducible and scientifically valid.

Summary Table:

| Feature | Function in Plant Preparation | Benefit to Analysis |

|---|---|---|

| Forced Airflow | Eliminates humidity pockets & uniform heat | Prevents sample "stewing" & uneven drying |

| Temperature (60°C) | Gentle moisture removal | Preserves heat-sensitive phytochemicals |

| Temperature (105°C) | Rapid, total dehydration | Ideal for biomass & ash content accuracy |

| Enzyme Inhibition | Halts biological/metabolic activity | Prevents chemical degradation of samples |

| Microbial Control | Removes moisture required for growth | Ensures long-term sample stability & storage |

Precision Sample Preparation with KINTEK

Don't let moisture variability compromise your research results. As a leader in laboratory heating solutions, KINTEK provides high-performance convection and vacuum systems designed to preserve the integrity of your most sensitive samples.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all customizable for your unique research needs. Whether you are drying biomass for energy calculations or preserving delicate plant compounds for pharmaceutical study, our equipment ensures the stabilization and uniformity your data demands.

Ready to elevate your lab's efficiency? Contact us today to find the perfect drying solution!

Visual Guide

References

- Janet Mbaluka Kivuva, Sebastian Chakeredza. Nutritional profiles and phytochemicals of sausage tree (Kigelia Africana) and moringa (Moringa oleifera) at Africa University, Zimbabwe. DOI: 10.22271/27893065.2025.v5.i2a.131

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What role does Thermogravimetric Analysis (TGA) play in determining the calcination parameters for manganese phosphate?

- Why is a pressurized environment necessary for HMF synthesis? Ensure Liquid Phase Stability at High Temperatures

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency

- Why is a high-precision blast drying oven used for Ni-Co/Ca catalyst preparation? Ensure Structural Integrity

- How does substrate preheating equipment affect the formation and distribution of the Laves phase in Inconel 718?

- Why is the base vacuum level of a magnetron co-sputtering system critical for Ru50Mo50(0001) alloy thin films?

- Why is a constant temperature blast drying oven necessary for biomass carbon impregnation? Optimize Material Structure

- What is the purpose of an industrial oven for powder pre-treatment? Ensure Accurate Silica Analysis