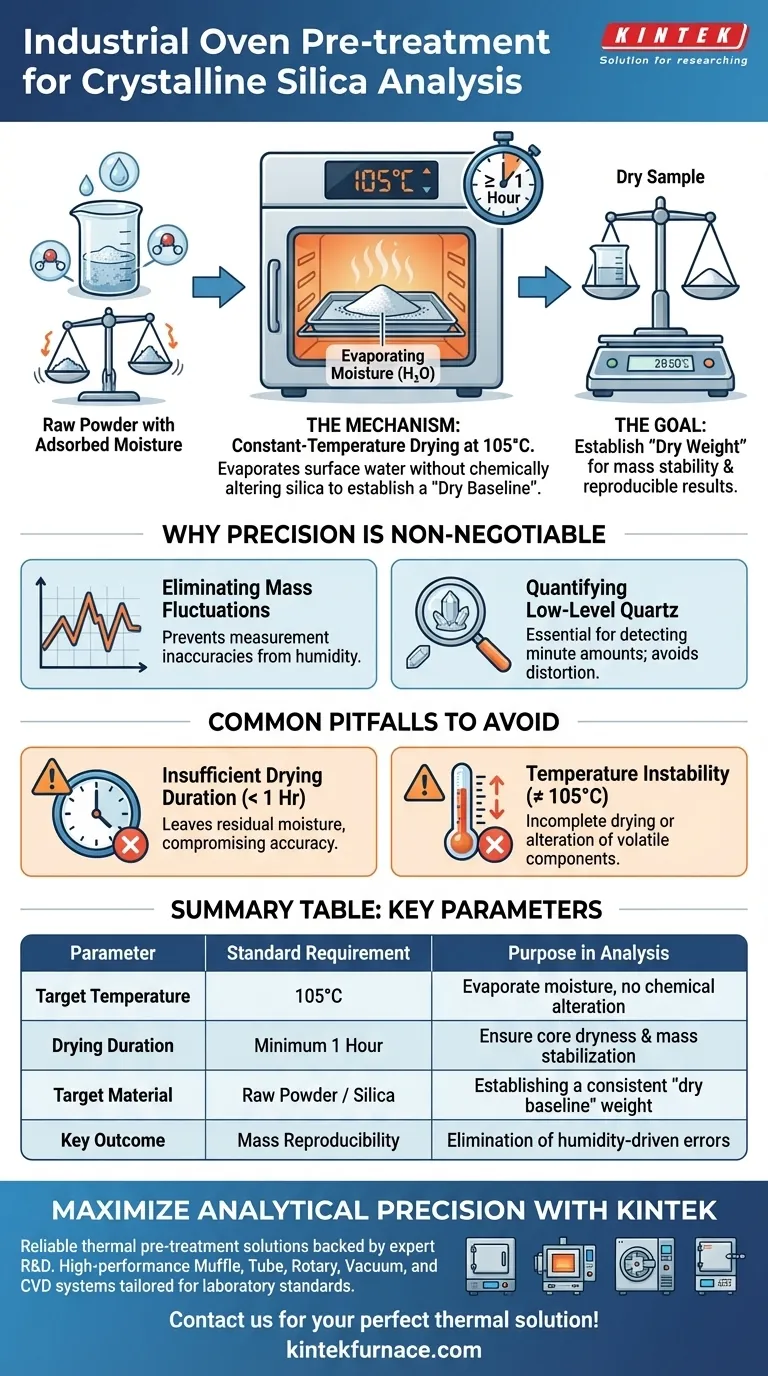

The primary function of an industrial oven in the context of respirable crystalline silica analysis is to stabilize the sample mass by removing adsorbed moisture. By subjecting raw powder materials to constant-temperature drying at 105°C for a minimum of one hour, analysts ensure that subsequent calculations are based on a verifiable, completely dry weight.

Variability in moisture content is a major source of error in gravimetric analysis. This thermal pre-treatment creates a standardized "dry baseline," ensuring that mass measurements reflect only the sample material and not the environmental humidity it has absorbed.

The Mechanism of Constant-Temperature Drying

Targeting Adsorbed Moisture

Raw powder materials naturally hold water molecules on their surface, known as adsorbed moisture. This moisture adds variable weight to the sample depending on the humidity of the storage environment.

The 105°C Standard

To effectively drive off this moisture without chemically altering the silica, the industrial oven is set to a constant temperature of 105°C. This temperature is sufficient to evaporate water while maintaining the integrity of the inorganic sample.

Establishing the Dry Weight

The ultimate goal is to reach a state of "dry weight." By removing the water variable, the mass percentages calculated during analysis become consistent and reproducible.

Why Precision is Non-Negotiable

Eliminating Mass Fluctuations

If a sample is weighed while holding moisture, the resulting data will be skewed. The pre-treatment eliminates measurement inaccuracies caused by these fluctuations, allowing for a true comparison of sample mass.

Quantifying Low-Level Quartz

Precision becomes even more vital when analyzing samples with low concentrations of target material. For the quantification of low-level quartz, even minute amounts of retained moisture can significantly distort the final percentage results.

Common Pitfalls to Avoid

Insufficient Drying Duration

The process requires a minimum duration of one hour to be effective. Shortening this timeframe may leave residual moisture in the center of the sample, compromising the accuracy of the entire analysis.

Temperature Instability

The oven must maintain a constant temperature. Fluctuations below 105°C may fail to fully dry the powder, while excessive heat could potentially alter other volatile components in a mixed sample matrix.

Ensuring Analytical Accuracy

To achieve reliable results in crystalline silica analysis, strict adherence to the pre-treatment protocol is essential.

- If your primary focus is Reproducibility: Ensure the oven maintains a stable 105°C to standardize the condition of every sample regardless of external humidity.

- If your primary focus is Sensitivity: Strictly adhere to the minimum one-hour duration to remove all traces of moisture that could mask low-level quartz detection.

Standardizing your drying process is the single most effective step to ensure your mass calculations represent the true composition of your material.

Summary Table:

| Parameter | Standard Requirement | Purpose in Analysis |

|---|---|---|

| Target Temperature | 105°C | Evaporate adsorbed moisture without chemical alteration |

| Drying Duration | Minimum 1 Hour | Ensure core dryness and mass stabilization |

| Target Material | Raw Powder / Silica | Establishing a consistent "dry baseline" weight |

| Key Outcome | Mass Reproducibility | Elimination of humidity-driven measurement errors |

Maximize Your Analytical Precision with KINTEK

Don't let moisture fluctuations compromise your crystalline silica results. At KINTEK, we understand that accuracy starts with reliable thermal pre-treatment. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for rigorous laboratory standards.

Whether you need a specialized industrial oven for sample drying or a custom high-temperature furnace for advanced material research, our solutions are engineered for stability and uniformity. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Tapani Tuomi, Jussi Lyyränen. Measuring Respirable Crystalline Silica (Quartz) from Powdery Materials through Sedimentation and X-ray Diffractometry. DOI: 10.3390/toxics12040241

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the "Flux Melting" process in MOF glass preparation utilize heating equipment? Low-Temp MOF Vitrification

- How does environmental control equipment assist in assessing CMS membranes? Unlock Precision in Physical Aging Tests

- Why is a high-pressure digestion tank essential for ZnO/rGO hydrothermal synthesis? Achieve superior interfacial coupling

- Why is immediate water quenching required for CuAlMn alloys? Master Phase Retention in Shape Memory Alloys

- What is the role of temperature control equipment in 60Si2CrV steel processing? Ensure Hardness and Longevity

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield

- Why is a final drying step necessary when restructuring adsorbents? Ensure Chemical Bonding & Industrial Safety

- What is the basic principle of a sintering furnace? Transform Powder into Dense, Strong Components