A nitrogen (N2) purging system is the primary defense against combustion and product loss. It is strictly necessary to displace oxygen within the heat treatment equipment before the process begins and continuously through the cooling phase. By maintaining this inert atmosphere, the system prevents the biomass from catching fire, ensuring it undergoes controlled thermal degradation rather than burning into ash.

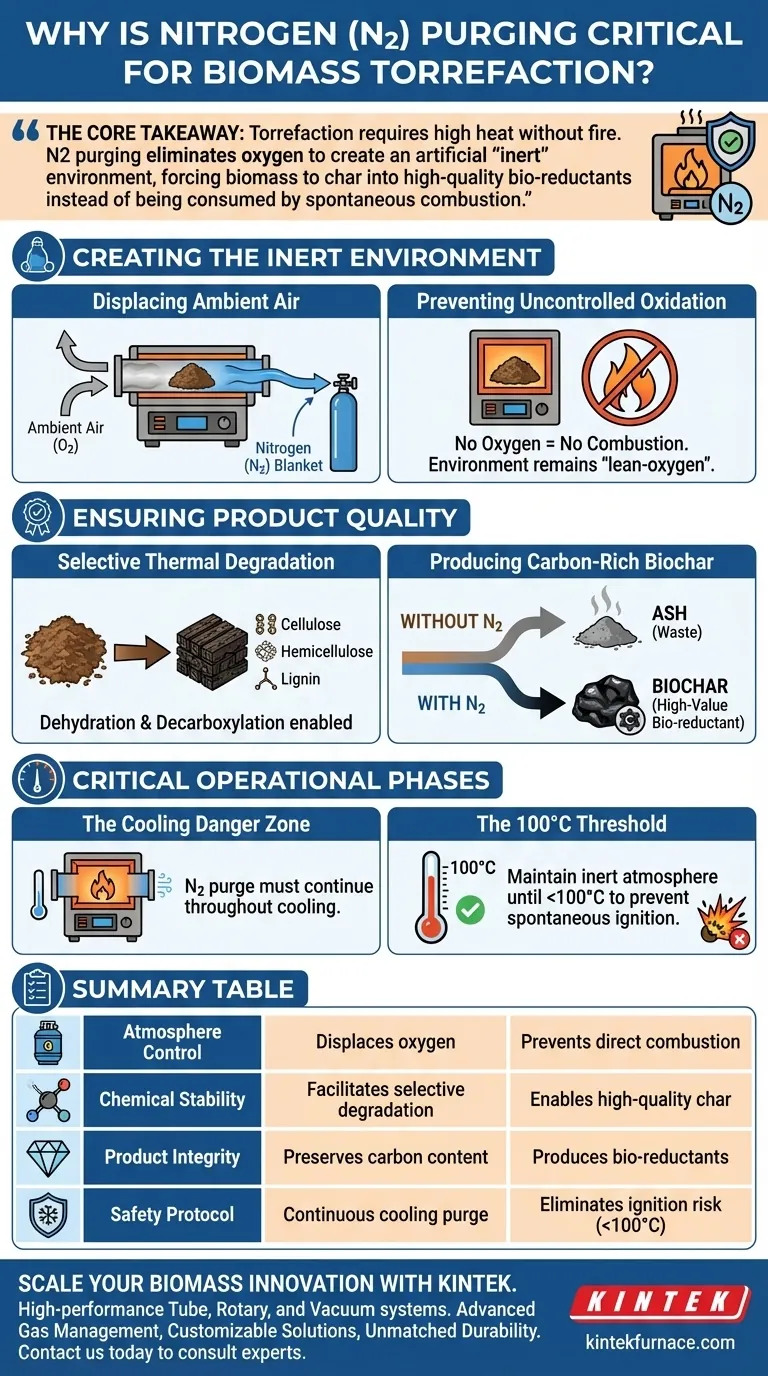

The Core Takeaway Torrefaction requires high heat without fire. Nitrogen purging eliminates oxygen to create an artificial "inert" environment, forcing biomass to char into high-quality bio-reductants instead of being consumed by spontaneous combustion.

Creating the Inert Environment

Displacing Ambient Air

Before the torrefaction process can begin, the heat treatment equipment is naturally filled with ambient air, which contains oxygen.

The nitrogen purging system is introduced specifically to displace this air. This creates a "blanket" around the biomass, removing the oxidant required for fire.

Preventing Uncontrolled Oxidation

Biomass is highly flammable when subjected to the high temperatures required for torrefaction.

Without an oxygen-deficient environment, the heat would trigger direct combustion. Nitrogen ensures that the environment remains "lean-oxygen" or oxygen-free, preventing the material from simply burning up.

Ensuring Product Quality

Selective Thermal Degradation

The goal of torrefaction is not to burn the material, but to chemically alter it.

Nitrogen allows for the selective thermal degradation of specific biomass components: cellulose, hemicellulose, and lignin. This occurs through dehydration and decarboxylation, processes that require heat but cannot function correctly in the presence of oxygen.

Producing Carbon-Rich Biochar

If oxygen is present, carbon reacts with it to form ash and gases.

By excluding oxygen, the nitrogen atmosphere preserves the carbon content within the solid material. This guarantees the production of high-quality carbonized solid products (bio-reductants) rather than waste ash.

Critical Operational Phases

The Cooling Danger Zone

The risk of fire does not end when the heating cycle finishes.

The primary reference explicitly states that the nitrogen purge must continue throughout the cooling phase. The biomass remains hot enough to ignite if suddenly exposed to fresh air during this time.

The 100°C Threshold

The system must maintain the inert atmosphere until the equipment and material temperature drops below 100°C.

Stopping the nitrogen flow before reaching this temperature creates an immediate risk of spontaneous combustion, potentially destroying the batch you just processed.

Understanding the Trade-offs

Consumable Costs vs. Product Value

Using a nitrogen system introduces an ongoing operational cost for the gas supply.

However, this cost is unavoidable; without it, the yield drops significantly as valuable biomass turns to ash. The expense of the gas is a trade-off for the high yield of the final carbonized product.

Process Complexity

Implementing this system requires precise control over gas flow and equipment sealing.

You must ensure the furnace or tube is sealed well enough to maintain the atmosphere. Leaks that allow oxygen ingress will degrade the quality of the biochar regardless of how much nitrogen is pumped in.

Making the Right Choice for Your Goal

To optimize your torrefaction process, align your purging strategy with your specific objectives:

- If your primary focus is safety: Rigorously automate the purging cycle to continue until the internal temperature is strictly below 100°C to prevent downstream fires.

- If your primary focus is product quality: Monitor the dew point and purity of the nitrogen supply to ensure efficient dehydration and maximum preservation of the carbon structure.

Proper nitrogen management is the single most critical factor in converting raw biomass into a high-value industrial fuel.

Summary Table:

| Feature | Role of Nitrogen Purging | Benefit to Torrefaction |

|---|---|---|

| Atmosphere Control | Displaces oxygen and ambient air | Prevents direct combustion and material loss |

| Chemical Stability | Facilitates dehydration/decarboxylation | Enables selective degradation of lignin and cellulose |

| Product Integrity | Preserves carbon content | Produces high-value bio-reductants instead of ash |

| Safety Protocol | Continuous cooling purge (<100°C) | Eliminates risk of spontaneous ignition during discharge |

Scale Your Biomass Innovation with KINTEK

Don't let oxygen-related product loss compromise your torrefaction yields. KINTEK provides high-performance, precision-engineered Tube, Rotary, and Vacuum systems designed specifically for sensitive thermal processes like biochar production.

Our equipment offers:

- Advanced Gas Management: Integrated N2 purging systems for airtight oxygen displacement.

- Customizable Solutions: R&D-backed designs tailored to your specific temperature and atmospheric requirements.

- Unmatched Durability: Industrial-grade manufacturing to withstand rigorous heating and cooling cycles.

Ready to optimize your lab or production facility? Contact us today to consult with our experts on the perfect high-temperature furnace for your needs.

Visual Guide

References

- Richard Deutsch, Gernot Krammer. Characteristics of High-Temperature Torrefied Wood Pellets for Use in a Blast Furnace Injection System. DOI: 10.3390/en18030458

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a secondary calcination furnace required after ball milling? Unlock High-Purity Hydroxyapatite Synthesis

- What is the objective of GC-MS analysis on bio-oil? Unlock Chemical Value and Industrial Utility

- Why is a high flow rate of synthetic air maintained during magnetite oxidation? Ensure Accurate Kinetic Modeling

- Why use nitrogen and flow meters in sludge pyrolysis? Ensuring Superior Biochar Quality and Anaerobic Integrity

- What is the function of a drying oven in the post-treatment process of Ni and Zn-doped MgO nanoparticles?

- How does plasma nitriding equipment improve the performance of titanium alloys in seawater? Boost Marine Durability

- How does a high-power microwave reactor facilitate the thermal treatment of zinc clinker? Rapid Phase Transformation

- What type of furnace was chosen for annealing silicon-based materials and what were the key requirements? Discover the Ideal Solution for Precise Heat Treatment