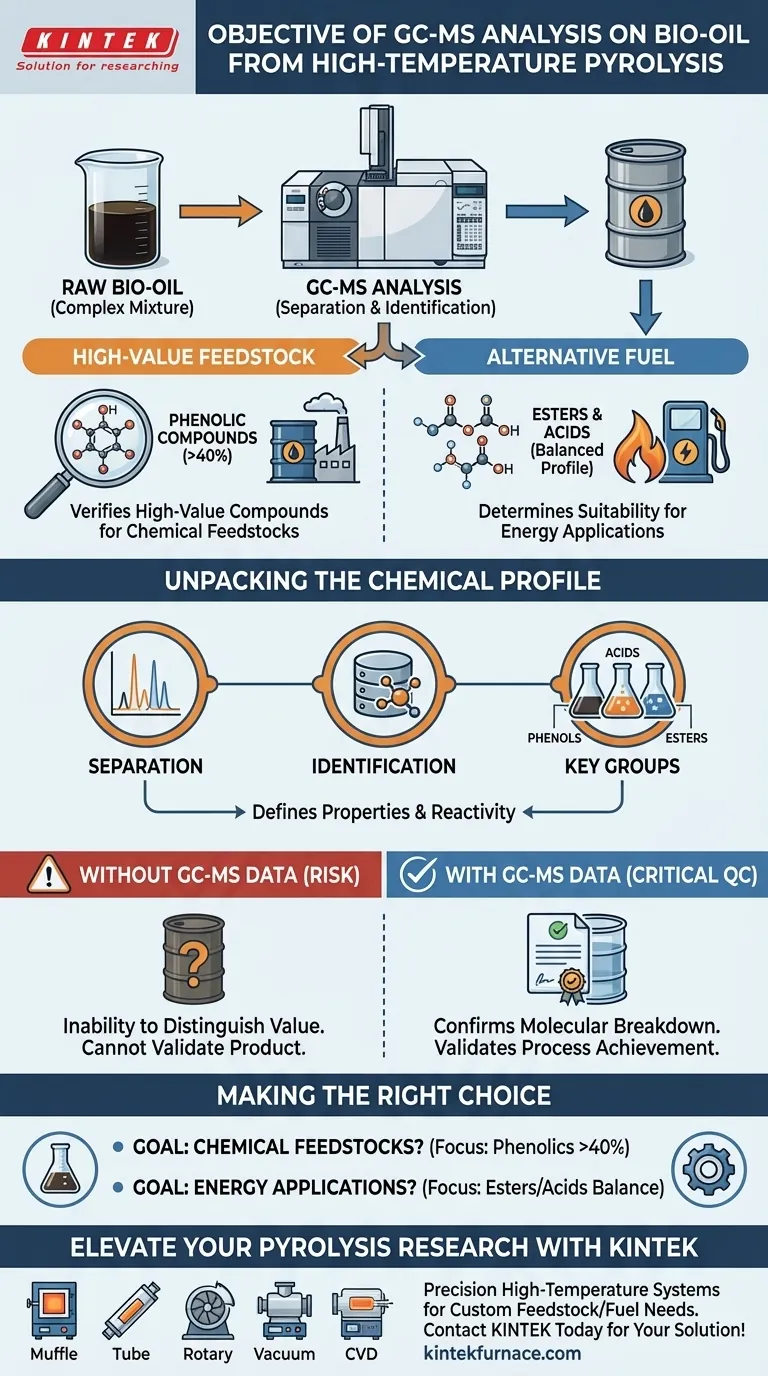

The primary objective of performing Gas Chromatography-Mass Spectrometry (GC-MS) on bio-oil derived from high-temperature furnace pyrolysis is to rigorously separate and identify its complex chemical constituents. This analytical process generates a detailed chemical profile, allowing researchers to verify the presence of high-value compounds and determine the oil's specific industrial utility.

GC-MS analysis moves bio-oil from a raw, unknown mixture to a defined product. By quantifying specific chemical groups, this analysis provides the decisive data needed to categorize the oil as either a source for high-value chemical feedstocks or a viable alternative fuel.

Unpacking the Chemical Profile

Separation and Identification

Bio-oil produced via high-temperature pyrolysis is a highly complex mixture. GC-MS is utilized to break down this mixture into individual components to understand its exact composition.

Identifying Key Functional Groups

The analysis specifically targets the identification of distinct chemical families. The primary groups of interest include phenols, acids, and esters, which define the oil's chemical properties and potential reactivity.

Determining Commercial Viability

Verifying High-Value Components

A major objective of this analysis is to assess the economic potential of the bio-oil. GC-MS is used to verify the concentration of lucrative chemicals, specifically looking for phenolic compounds exceeding 40%.

Defining the End-Use Case

The chemical profile dictates the final application of the product. Data showing high concentrations of specific compounds supports use as a chemical feedstock, whereas different profiles determines suitability as an alternative fuel.

Understanding the Stakes

The Risk of Lack of Data

The trade-off in skipping or under-utilizing GC-MS analysis is the inability to distinguish value. Without a detailed chemical profile, it is impossible to validate whether the bio-oil is a commodity product or a simple fuel.

Critical Quality Control

Reliance on general physical properties alone is insufficient for high-temperature pyrolysis products. The specific molecular breakdown provided by GC-MS is the only way to confirm that the pyrolysis process achieved the desired chemical transformation.

Making the Right Choice for Your Goal

To maximize the value of your bio-oil analysis, align your interpretation of the GC-MS data with your specific end goals:

- If your primary focus is Chemical Feedstocks: Prioritize the quantification of phenolic compounds to confirm they meet or exceed the 40% concentration threshold.

- If your primary focus is Energy Applications: Analyze the profile for a balance of esters and acids that suggests stability and suitability for combustion as an alternative fuel.

GC-MS analysis provides the essential evidentiary basis required to certify bio-oil for specific industrial applications.

Summary Table:

| Analytical Objective | Key Components Identified | Industrial Outcome |

|---|---|---|

| Chemical Separation | Complex mixture of organic molecules | Detailed chemical fingerprinting |

| Functional Grouping | Phenols, acids, and esters | Definition of chemical reactivity |

| Economic Valuation | High-value chemicals (>40% phenols) | Validation as premium feedstock |

| Application Definition | Esters and volatile organic compounds | Determination as alternative fuel |

Elevate Your Pyrolysis Research with KINTEK

Maximize the potential of your bio-oil production with precision equipment designed for high-performance research. Backed by expert R&D and manufacturing, KINTEK offers high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique chemical feedstock or fuel development needs.

Ready to achieve superior chemical transformation? Contact us today to find your custom lab furnace solution!

Visual Guide

References

- Hussien Elshareef, Yuguang Zhou. Investigation of Bio-Oil and Biochar Derived from Cotton Stalk Pyrolysis: Effect of Different Reaction Conditions. DOI: 10.3390/resources14050075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- What role does a nitrogen curtain protection system play in copper tube welding? Ensure Peak Joint Integrity

- Why is instantaneous heating required for N-GC-X catalyst synthesis? Achieve Superior 2D Nanosheet Morphology

- Why is staged temperature control required in industrial air drying ovens for carbon nanofibers? Key Safety Insights

- Why is a vacuum oven preferred for drying MXene-modified electrodes? Optimize Your Lab's Electrochemical Success

- What role does high-temperature calcination play in the purification of volcanic ash? Achieve Ultra-Pure Silica Results

- Why is encapsulation with hBN or graphene required during TMD annealing? Shielding Your 2D Materials

- What is the synergistic effect of industrial fly ash in beet pulp porous carbons? Enhance 3D Structural Performance

- Why is a heating device required when evaluating HEAs? Unlocking High-Temperature Material Performance